Method and apparatus for generating gas pulses

A gas pressure pulse and gas technology, which is applied in the direction of cleaning methods, cleaning methods and utensils, and combustion methods using gas flow, which can solve problems such as difficulty in implementing inner surfaces, hardening of dust, and erosion of pipe surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

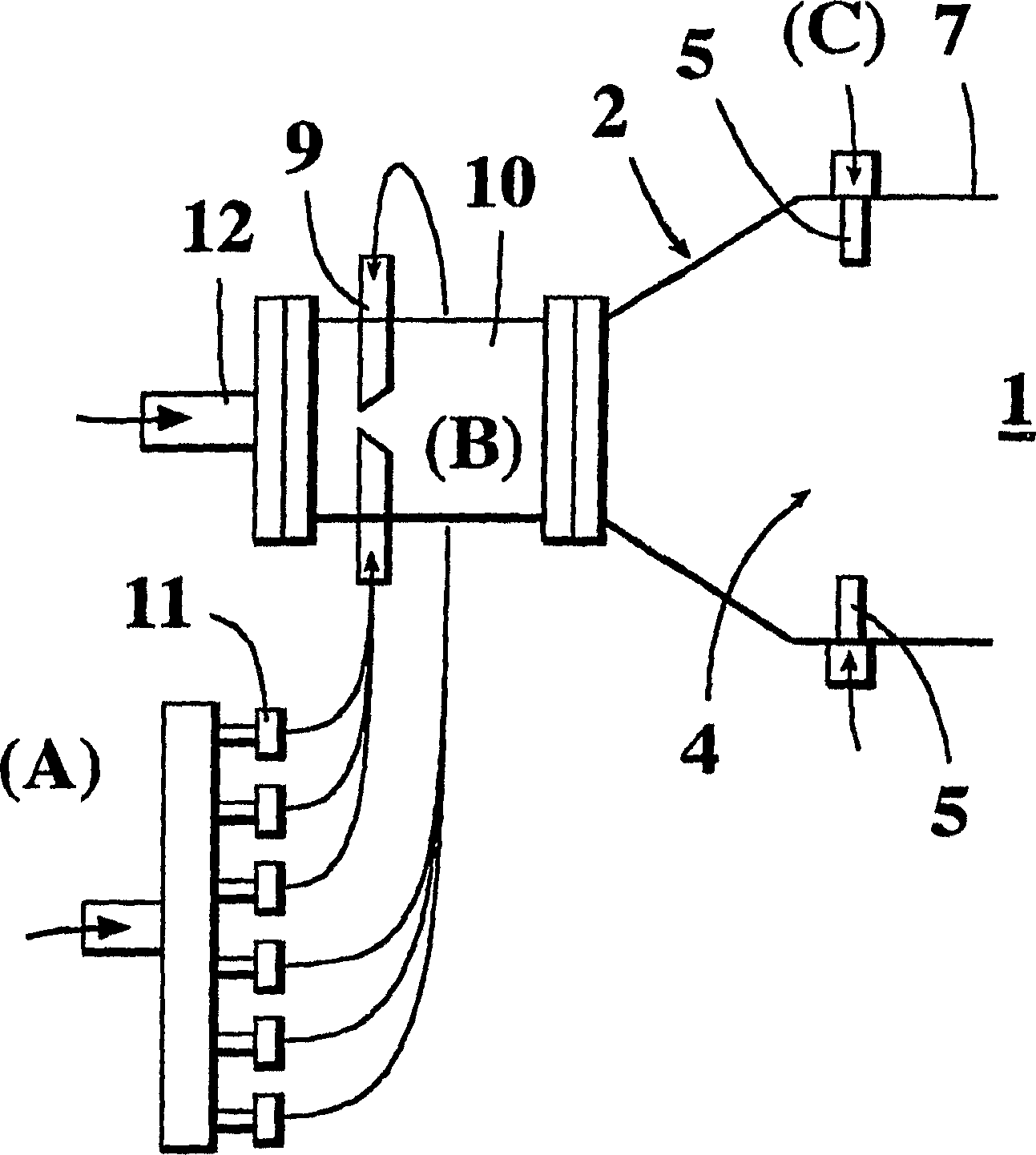

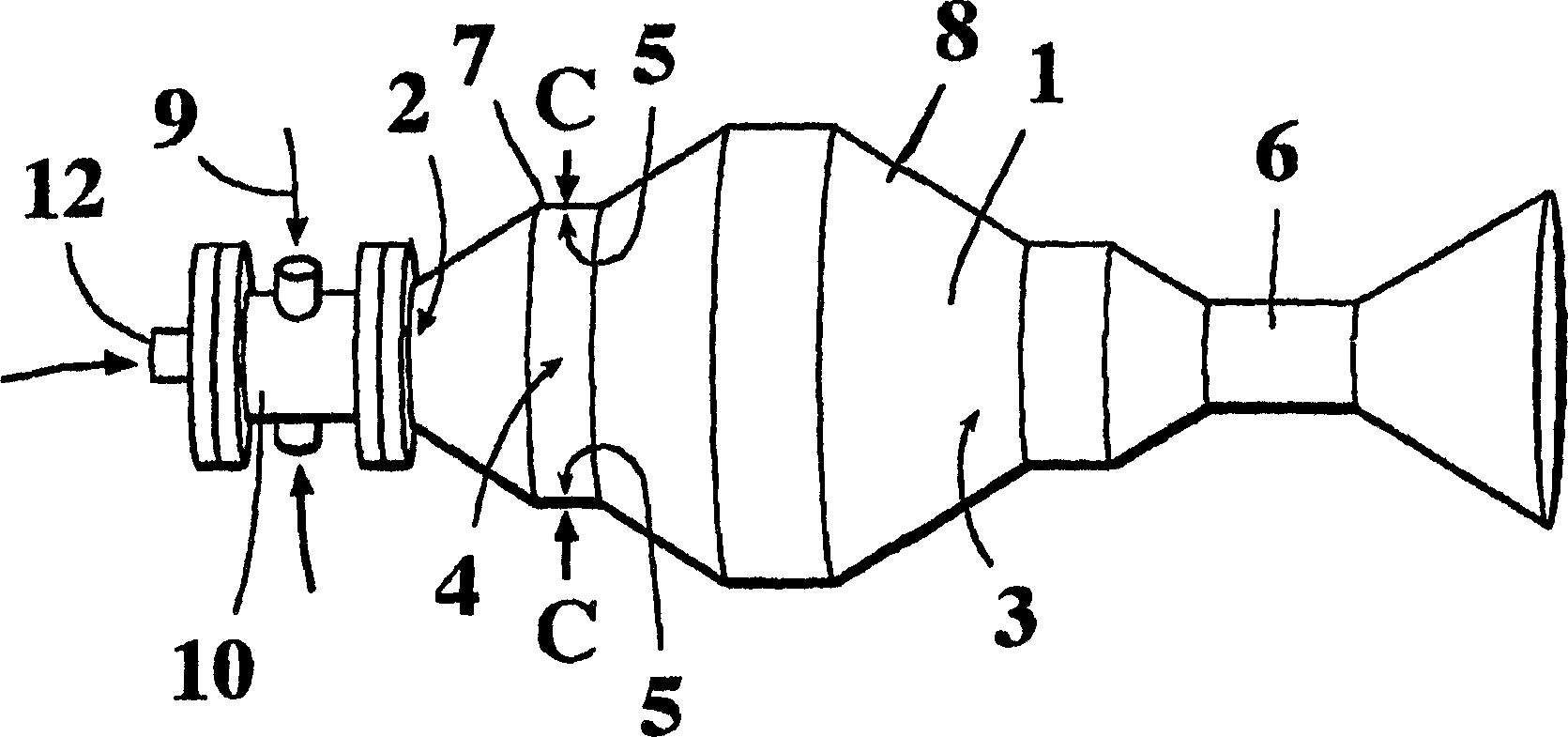

[0049] have as figure 2 The combustion chamber of the configuration shown has a length of 560 mm, a diameter of 168 mm in the cylindrical part and a minimum diameter of 66 mm where the horn begins to open. The spark plug (3) is located at a distance from the round end ( figure 1 C) 84 mm, symmetrically arranged along the periphery of the combustion chamber, forming an angle of 120 degrees with each other. The overall length of the horn is 1340mm and it is provided with two different cones, the first 40mm-250mm and the second 250mm-350mm.

[0050] The combustible gas (driver gas) used is propane, which is mixed with air, and at an operating frequency of 10 Hz, a sound level of 170 decibels can be achieved by burning only 370 milligrams of propane per explosion.

[0051] In contrast, during earlier tests using a different combustion chamber with an elongated, substantially all the way cylindrical shape, 2000 mg of propane was burned per detonation to obtain the same acoustic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com