Antistatic decorative slice for suppressing bend whitening

An antistatic agent and sheet technology, which can be used in static electricity, household refrigeration devices, manufacturing tools, etc., can solve the problems of secondary processing obstacles, lack of sustainability of effects, and damage to the appearance of decorative sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

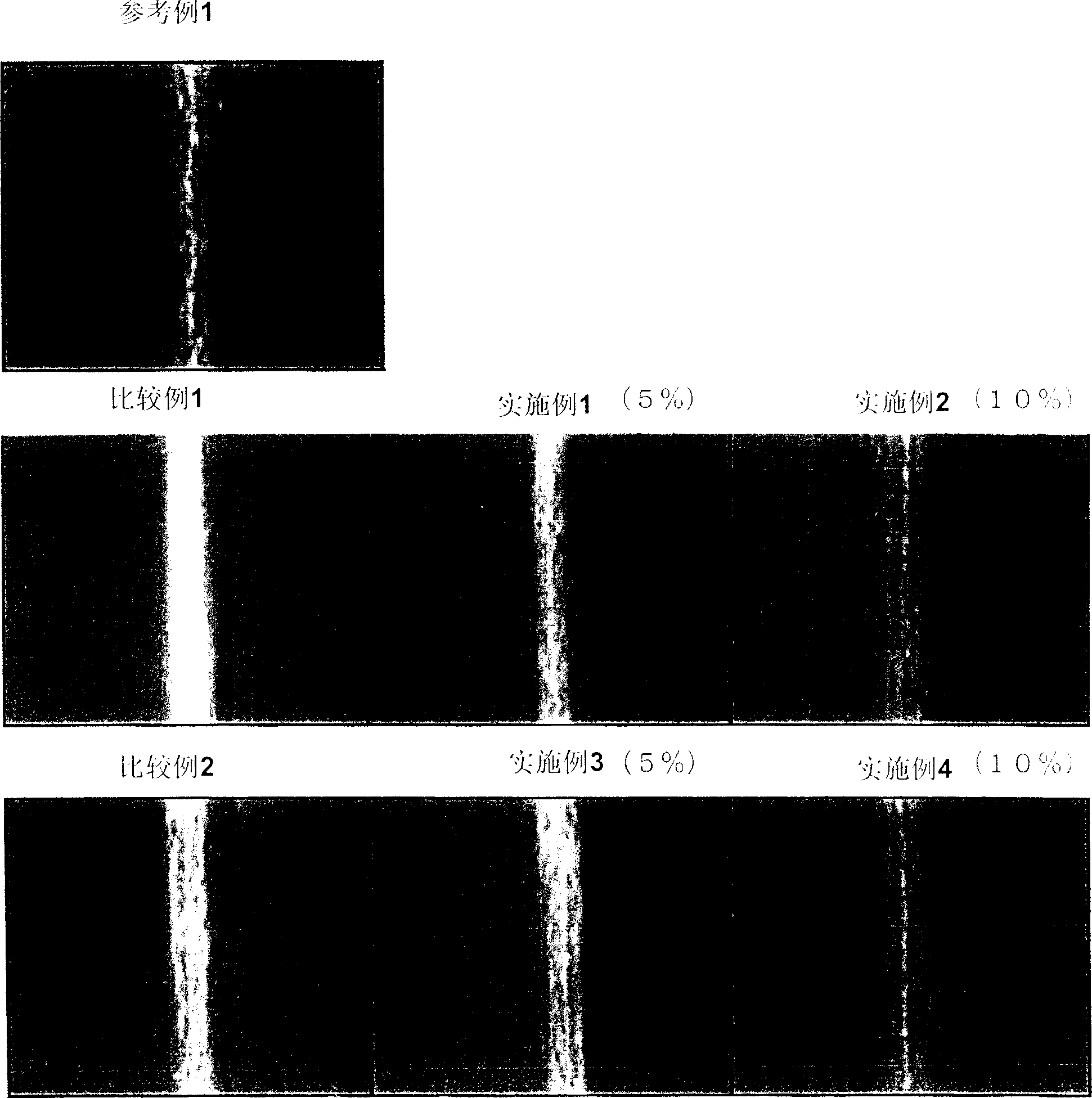

Embodiment 1

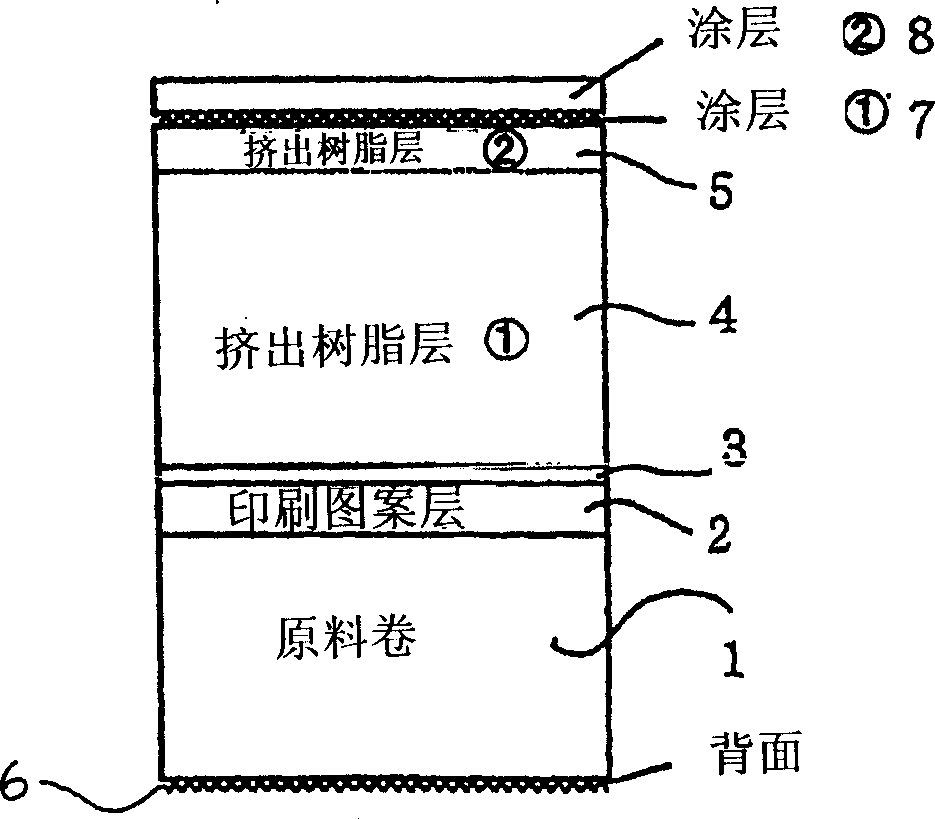

[0132] produced with figure 2 Decorative flakes of the structure shown.

[0133] (1) Fabrication of a sheet having a polyolefin resin layer

[0134] A colored polypropylene-based resin film 1 (thickness 80 μm) was prepared by adding 10% by weight of a coloring material (titanium oxide), and corona discharge treatment was applied to the outer surface and the back surface. Colored ink gravure printing (full pattern) with a two-component curing type urethane resin as a binder is applied to the outer surface, and a pattern layer of a wood grain pattern is formed thereon with an ink with an acrylic resin as a binder 2. In addition, a primer layer 6 using a polyurethane resin as a binder was formed on the back surface using gravure printing to obtain a printed sheet.

[0135] Next, on the pattern layer 2 of the above-mentioned printed sheet, after forming the adhesive layer 3 made of two-component curing polyurethane resin with a thickness of 15 μm, two layers consisting of the ...

Embodiment 2

[0141] Except having made content of a compatibilizing agent into 10 weight%, it carried out similarly to Example 1, and produced the decorative sheet.

Embodiment 3

[0143] Except that the macromolecular antistatic agent is changed into polyether-ester-amide macromolecular antistatic agent (product name " IRGASTATP18 ", produced by Ciba Specialty Chemicals Inc.), proceed in the same way as in Example 1, and make a decorative sheet .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com