Transmission mechanism of screen printer

A screen printing machine and transmission mechanism technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of insufficient synchronous action precision, complex transmission mechanism, and inability to meet the requirements of multi-color screen printing machines. , to achieve the effect of simple structure, high transmission precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

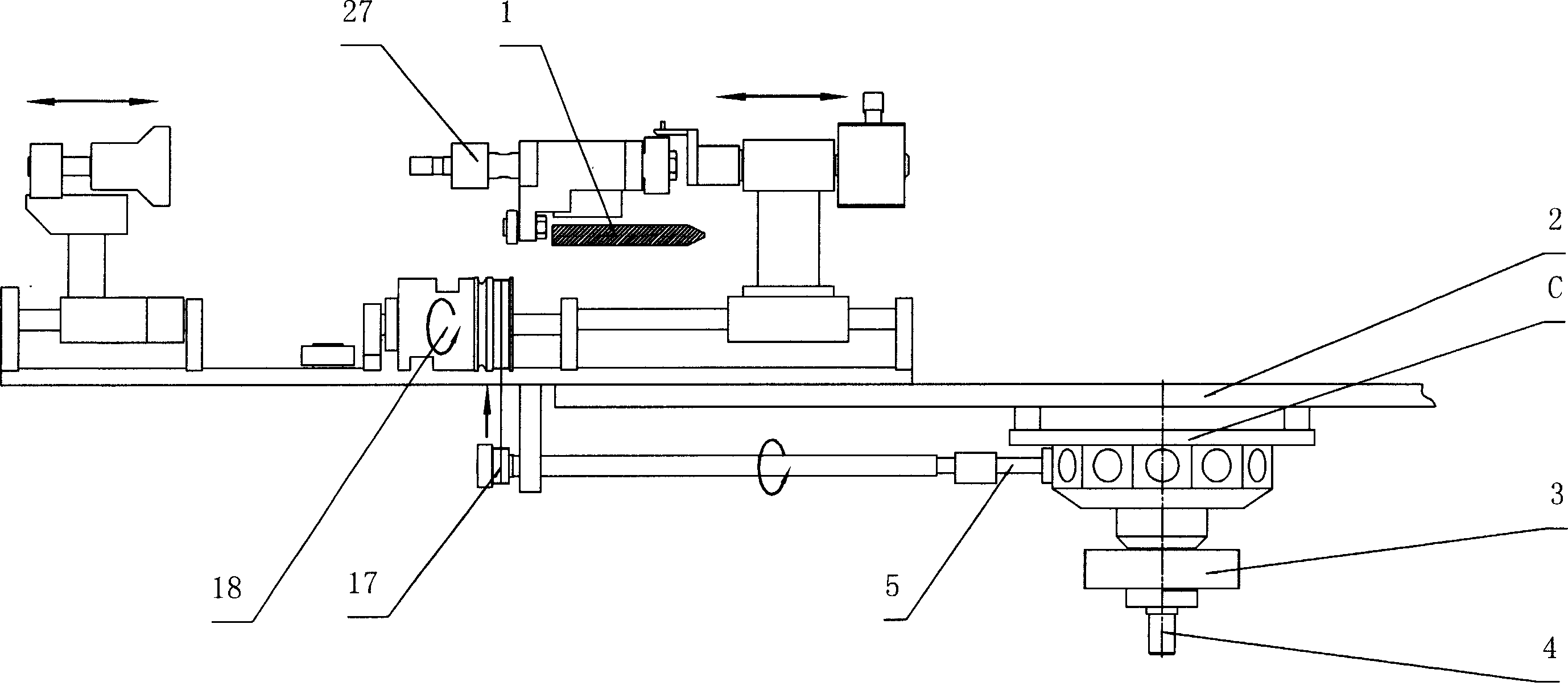

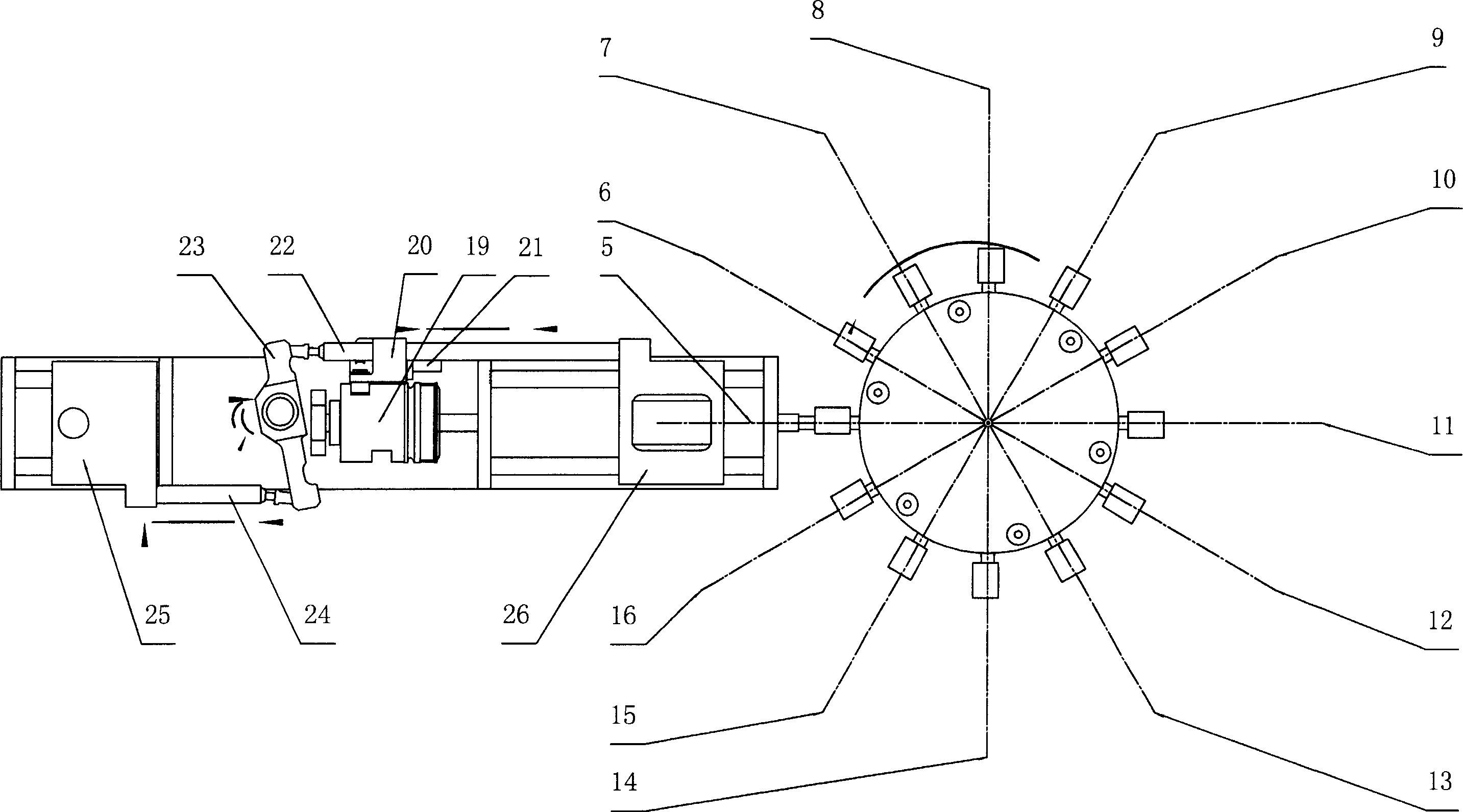

[0023] The structure diagram of the present invention is as figure 1 , 2 As shown, it includes a frame 2, a multi-power output device C provided with an input shaft 4 and several output shafts B, and the multi-power output device C is installed on the frame 2, and three or more of the several output shafts B The output shaft drives the shaft cam opening and closing mechanism 18 that produces linear motion opening and closing action through the synchronous transmission mechanism 17 on each printing position. In this embodiment, the multi-power output device C is installed in the middle of the frame 2 .

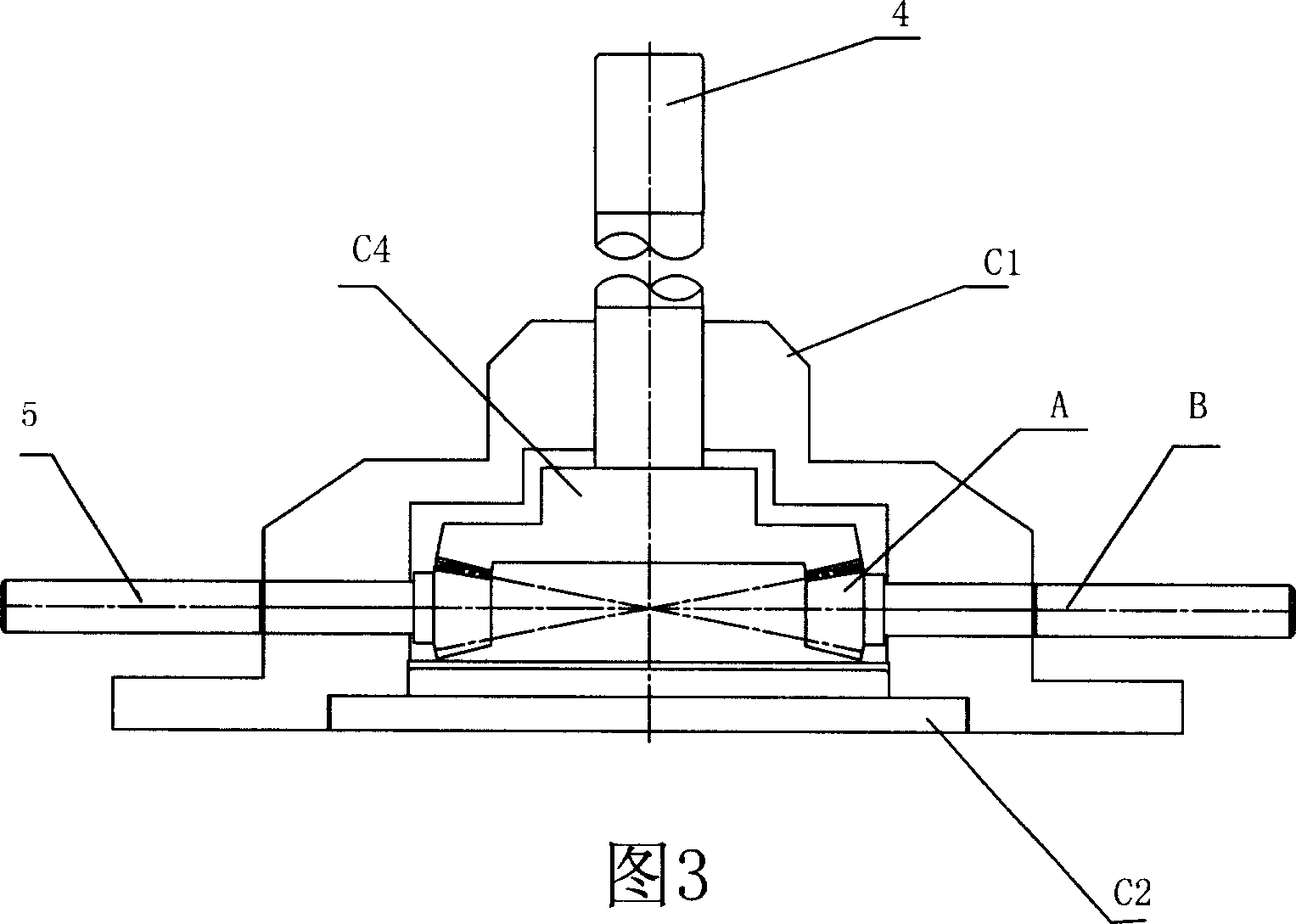

[0024] In this embodiment, the shaft cam opening and closing mechanism 18 includes a shaft cam 19, a slider 20, a slide rail 21, a front connecting rod 22, a crank block 23, a rear connecting rod 24, a rear sliding seat 25, and a front sliding seat 26. The shaft cam 19 which is provided with the cam groove is coaxially connected with the follower of the synchronous transmissi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap