Regulator and method for controlling microstructure of butadiene homopolymer and copolymer

A technology of microstructure and regulator, which is applied in the field of butadiene anionic polymerization, can solve problems such as the inability to stably control the vinyl content of polybutadiene, and the temperature sensitivity of polarity regulator polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

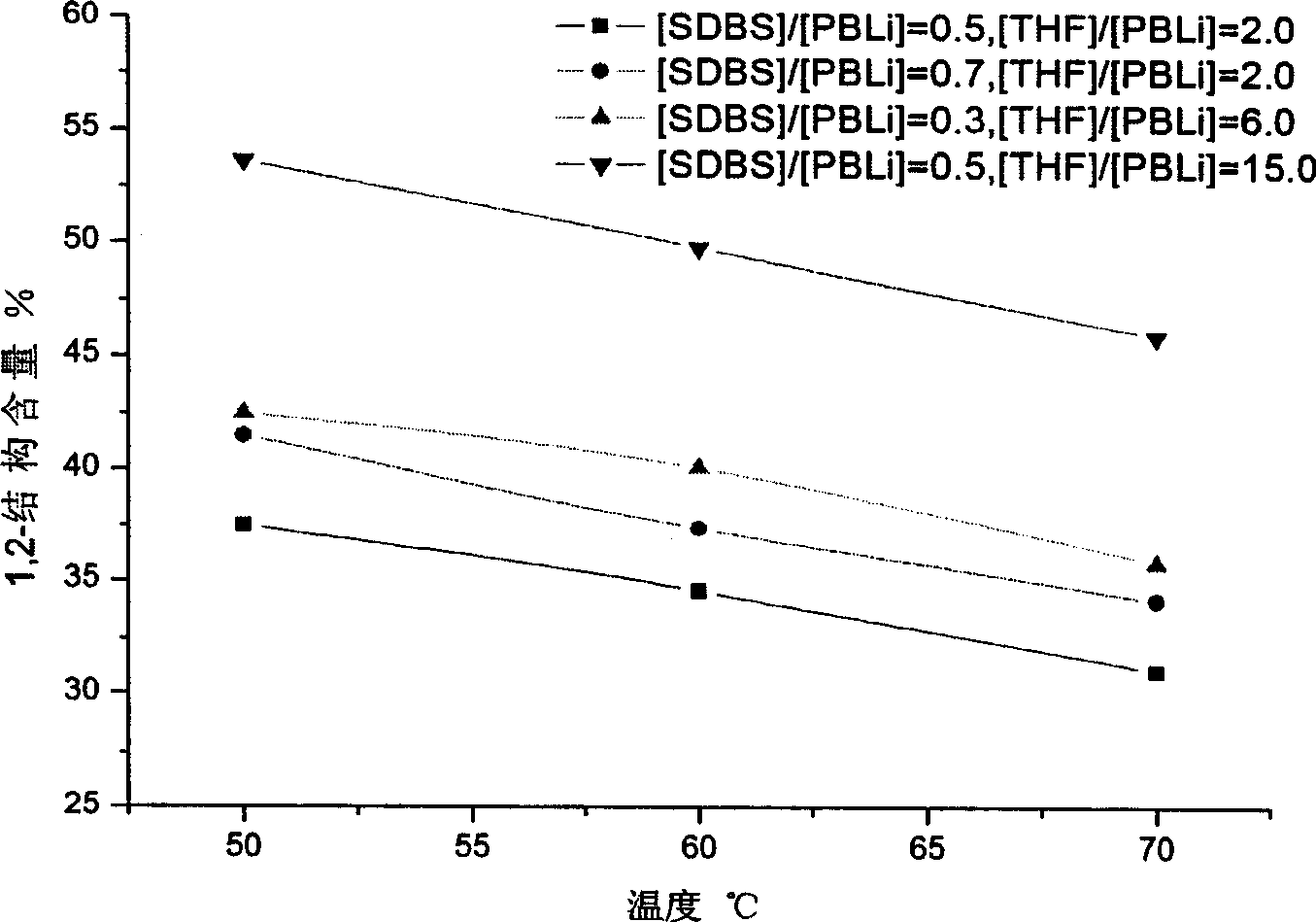

[0021] Take three 250ml polymerization bottles with double-branched tubes, first bake at high temperature, and replace nitrogen more than three times. Then pipette 100ml of butadiene-cyclohexane solution (concentration: 10g butadiene / 100ml cyclohexane solution) respectively, and add to each polymerization bottle. Use the binary composite regulator system of tetrahydrofuran (hereinafter referred to as THF) / sodium dodecylbenzenesulfonate (hereinafter referred to as SDBS), [THF] / [PBLi]=2.0, [SDBS] / [PBLi]=0.3, with n-Butyllithium n-BuLi was used as the initiator (0.85M concentration). First use n-butyllithium initiator to remove impurities, then add 0.24ml of n-butyllithium (design molecular weight is 50000), and carry out polymerization in water baths with constant temperature of 50°C, 60°C, and 70°C respectively, and the polymerization time is 2 hours . After the polymerization, the reaction was terminated with ethanol, and then the polymer was precipitated with ethanol, and d...

Embodiment 2

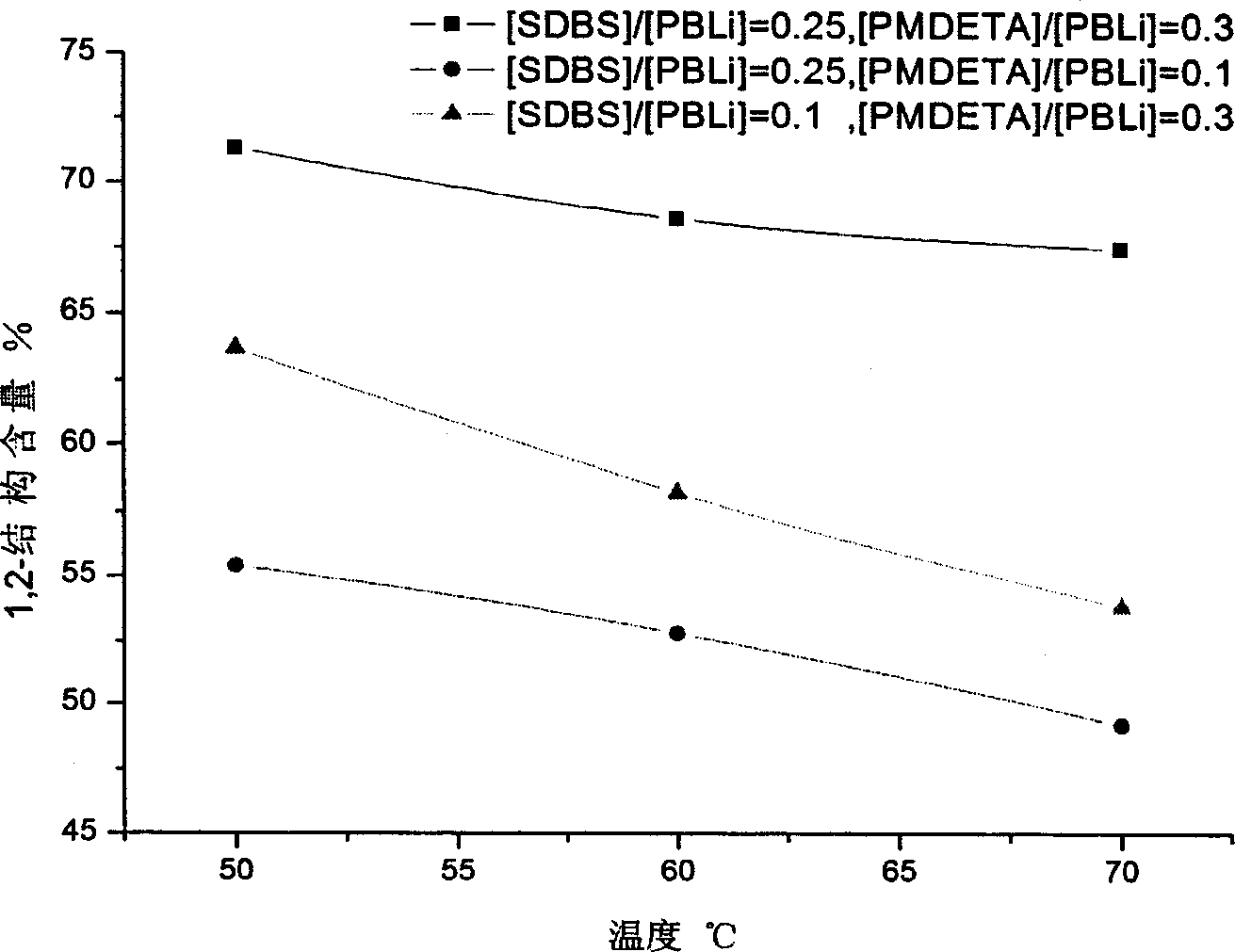

[0025] Substitute THF in embodiment 1 with pentamethyldivinyltriamine (hereinafter referred to as PMDETA), form the binary composite regulator system of SDBS / PMDETA, all the other polymerization conditions are similar to embodiment 1, according to change PMDETA and SDBS in the system The dosage is different from the active center concentration [PBLi] molar ratio, and can be correspondingly obtained figure 2 . Depend on figure 2 It can be seen that when PMDETA and SDBS are fixed, the 1,2-structure content of the sample decreases slowly with the increase of temperature, and the temperature rises by 20°C, and the 1,2-structure content only decreases by about 6%. Out of very good temperature insensitivity. The measured Mn is about 55000, and the MWD is between 1.2 and 1.3.

Embodiment 3

[0027] Take a 250ml polymerization bottle with a double-branched tube, first bake it at high temperature, and replace the nitrogen more than 3 times. Then use a pipette to pipette 100 ml of butadiene in hexane (concentration: 15 g of butadiene / 100 ml of hexane solution), and add it to the polymerization bottle. Use the binary compound regulator system of PMDETA / SDBS, [SDBS] / [PBLi]=0.3, [PMDETA] / [PBLi]=0.5, take n-butyllithium n-BuLi as initiator, (concentration is 0.85M) . First use n-butyllithium initiator to remove impurities, then add 0.22ml of n-butyllithium (design molecular weight is 80000), and carry out polymerization in a water bath with a constant temperature of 50°C, and the polymerization time is 2 hours. After the polymerization, the reaction was terminated with ethanol, and the polymer was precipitated with ethanol, and dried in a vacuum oven at 50°C. The 1,2-structure content of the sample was analyzed by nuclear magnetic resonance NMR to obtain the content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com