Halobacterium jilantaiense and application thereof

A technology of halophilic bacteria and lipase, applied to halophilic bacteria gilante and its application fields, can solve the problems of application limitation, activity reduction, inactivation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. Isolation and Identification of Halobacterium jilantaiense AC3 CGMCC No.1594

[0020] 1. The acquisition and biological characteristics of Halobacterium jilantaiense AC3 CGMCC No.1594

[0021] Show through culture experiment, this bacterium has following characteristics: (1) bacterium colony characteristic: on milk salt plate (150mL of skimmed milk, inorganic salt solution (MgSO 4 ·7H 2 O 3g, NaCl 60g, KNO 3 0.6g, 0.5mg ferric citrate) 30mL, agar solution (Casamino acid 1.5g, glycerin 3g, agar 4.5g) 120ml) for 7 days, the colony is round, the diameter of the colony is 0.5-2.1mm, the surface is smooth and the edges are neat , raised, cinnamon red. (2) Halobacterium jilantaiense AC3 CGMCC No.1594 strain grows strictly aerobically; the suitable pH range for growth is 6-9, and the optimum growth pH range is 7.5-8.5; the growth temperature range is 35-45°C, The optimum temperature is 40°C; the cells are short rod-shaped; Gram staining is negative; the cell si...

Embodiment 2

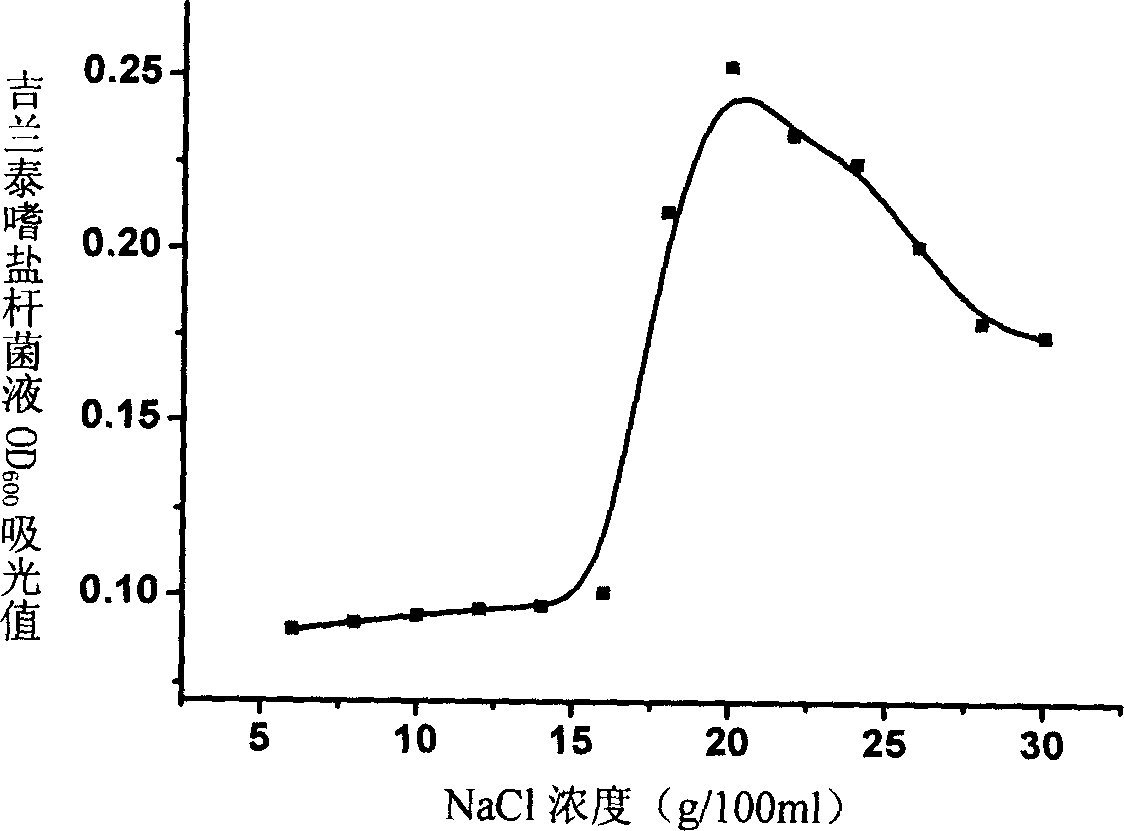

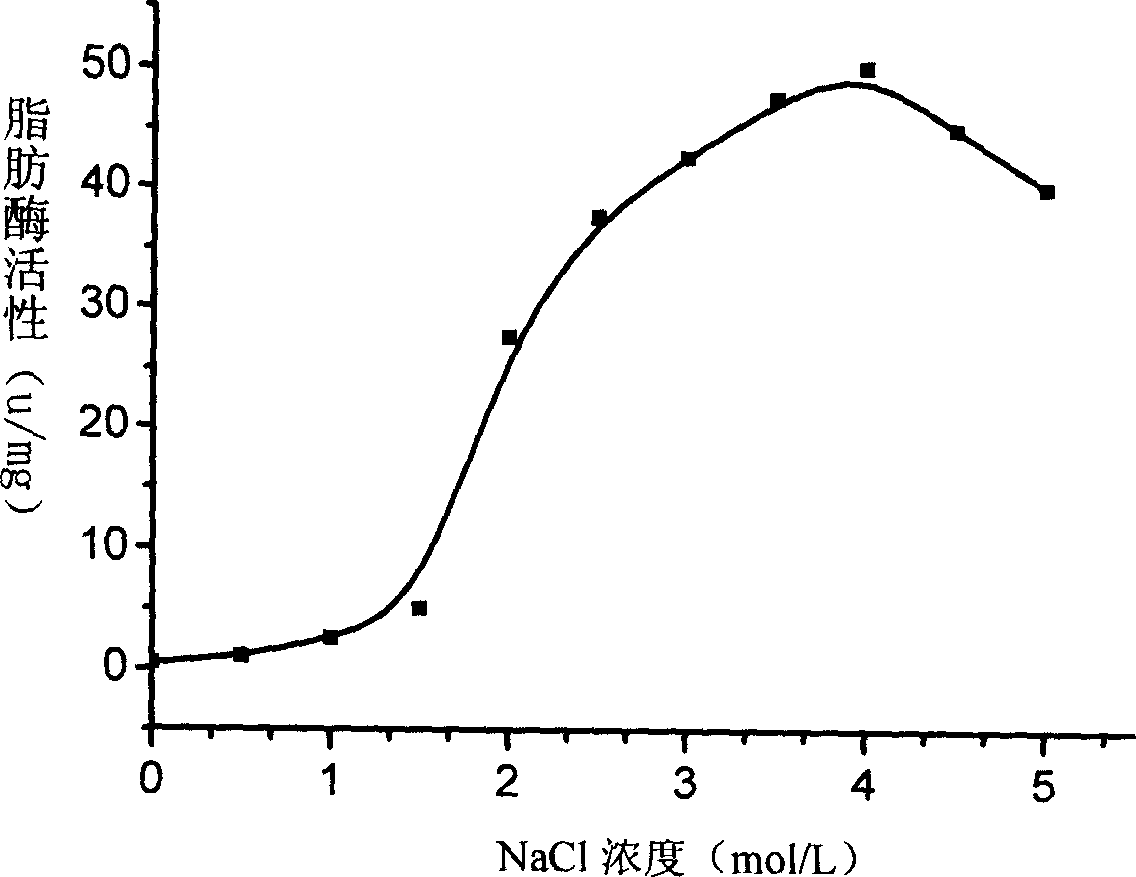

[0026] Example 2, the growth of Halobacterium jilantaiense AC3 CGMCC No.1594 under different NaCl concentration conditions and the substrate scope of the lipase it produces

[0027] 1. Growth of Halobacterium jilantaiense AC3 CGMCC No.1594 under different NaCl concentrations

[0028] Halobacterium jilantaiense (Halobacterium jilantaiense) AC3 CGMCC No.1594 was respectively inoculated in 0.75g / 100ml casamino acid (Casamino acid, Difco), 1g / 100ml yeast extract (Yeast extract, Oxoid), 0.3 g / 100ml (0.068M) trisodium citrate trihydrate, magnesium sulfate heptahydrate 2.0g / 100ml (0.081M), potassium chloride 0.2g / 100ml (0.0268M), ferrous sulfate heptahydrate 0.05g / 100ml (0.00018 M), sodium chloride concentrations are 6g / 100ml (1.03M), 8g / 100ml (1.36M), 10g / 100ml (1.7M), 12g / 100ml (2.05M), 14g / 100ml (2.40M), 16g / 100ml(2.74M), 18g / 100ml(3.08M), 20g / 100ml(3.42M), 22g / 100ml(3.76M), 24g / 100ml(4.11M), 26g / 100ml(4.45M), 28g / 100ml (4.80M), 30g / 100ml (5.13M) and 1000ml of distilled water i...

Embodiment 3

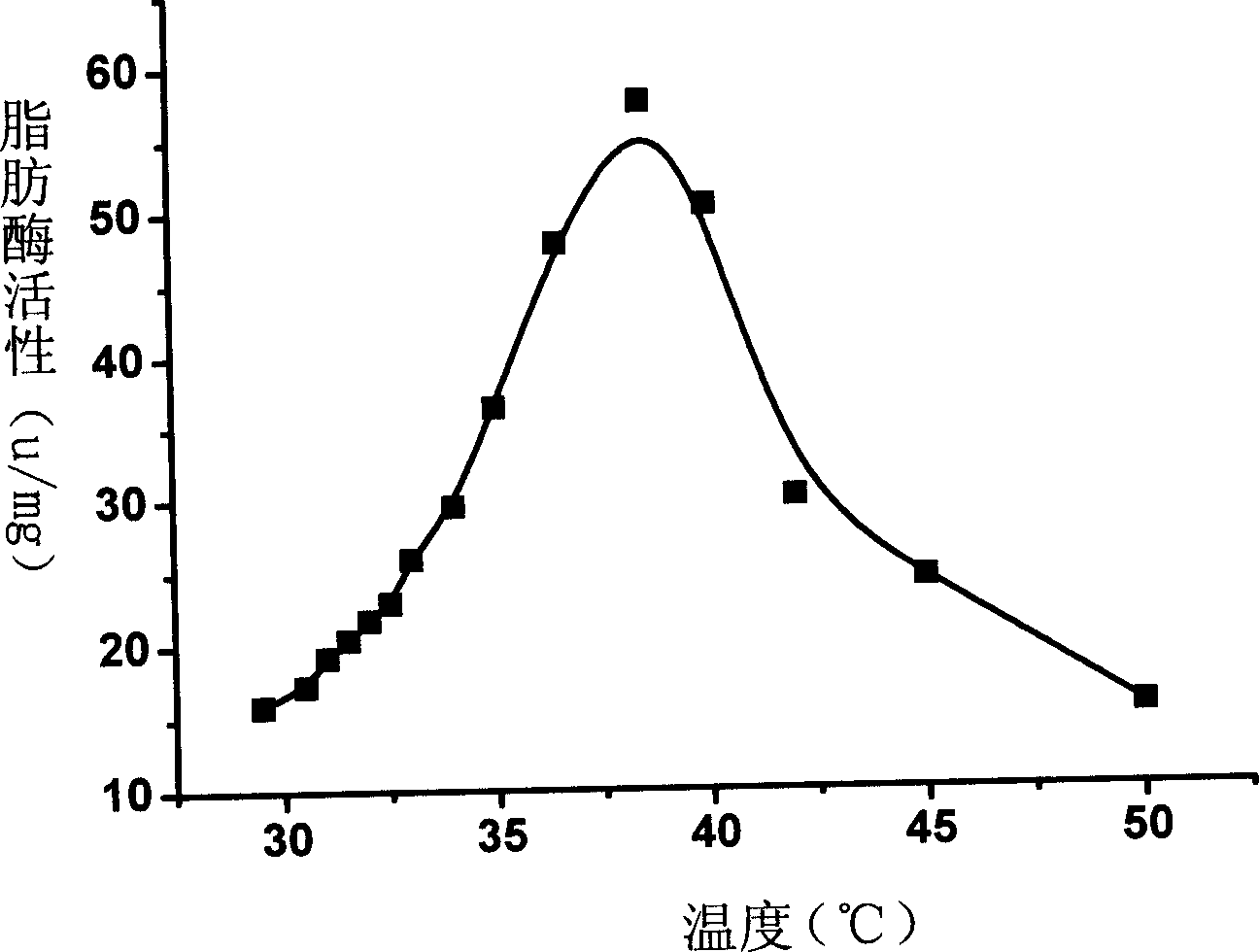

[0031] Example 3, Purification of lipase produced by Halobacterium jilantaiense AC3 CGMCC No.1594 and determination of enzyme activity:

[0032] 1. Purification of lipase produced by Halobacterium jilantaiense AC3 CGMCC No.1594

[0033] Halobacterium jilantaiense AC3 CGMCC No.1594 was cultured in the following CM liquid medium: Casamino acid (Difco) 7.5g, Yeast extract (Oxoid) 10.0g, MgSO 4 ·7H 2 O 20.0g, Trisodium citrate 3.0g, KCl 2.0g, FeSO 4 ·7H 2 O 0.05g, NaCl 200g, distilled water 1000ml, adjust the pH to 7.0-7.4 with 1M NaOH, and sterilize at 121°C for 30 minutes. Cultivate at 40°C, light and ventilate (the amount of liquid filled is 1 / 5 of the volume of the shake flask, the radius of rotation is 35 mm, and 200 rpm) for 5-7 days. Centrifuge the cultured bacterial solution at 8,000-12,000 rpm for 5-10 minutes, add 20-30% volume of acetone to the supernatant, centrifuge at 8,000-12,000 rpm for 5-10 minutes, and store the collected precipitate on ice Dissolve in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com