Method for growth of gallium arsenide monocrystal by gradient freeze method in horizontal three-temperature-zone furnace

A gradient solidification, three-temperature zone technology, applied in the direction of self-solidification, chemical instruments and methods, single crystal growth, etc., can solve the problems of unsatisfactory single crystal formation, easy softening of quartz tubes, complex structure, etc., and reduce fixed assets. The effect of investment, simplified process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

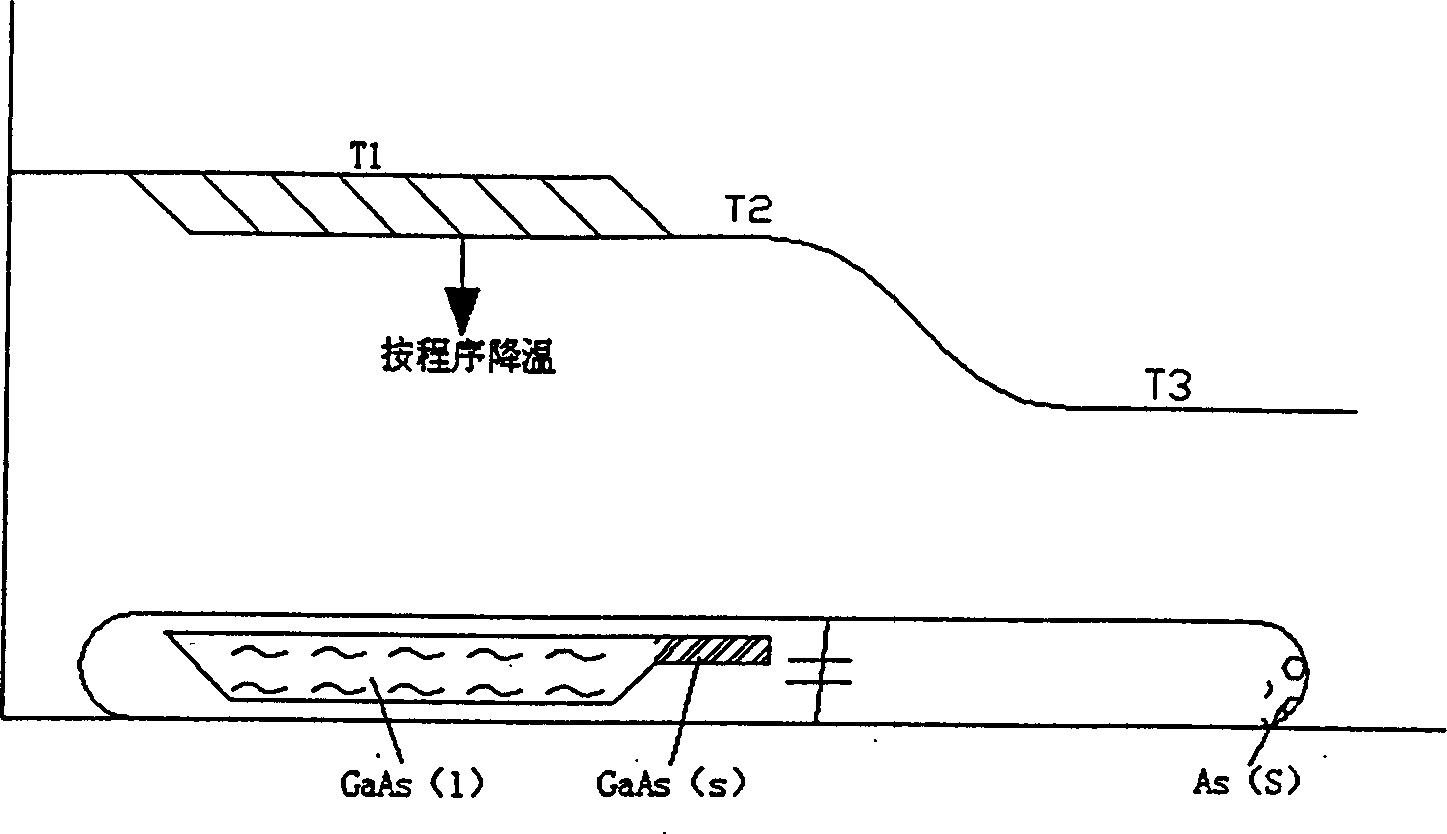

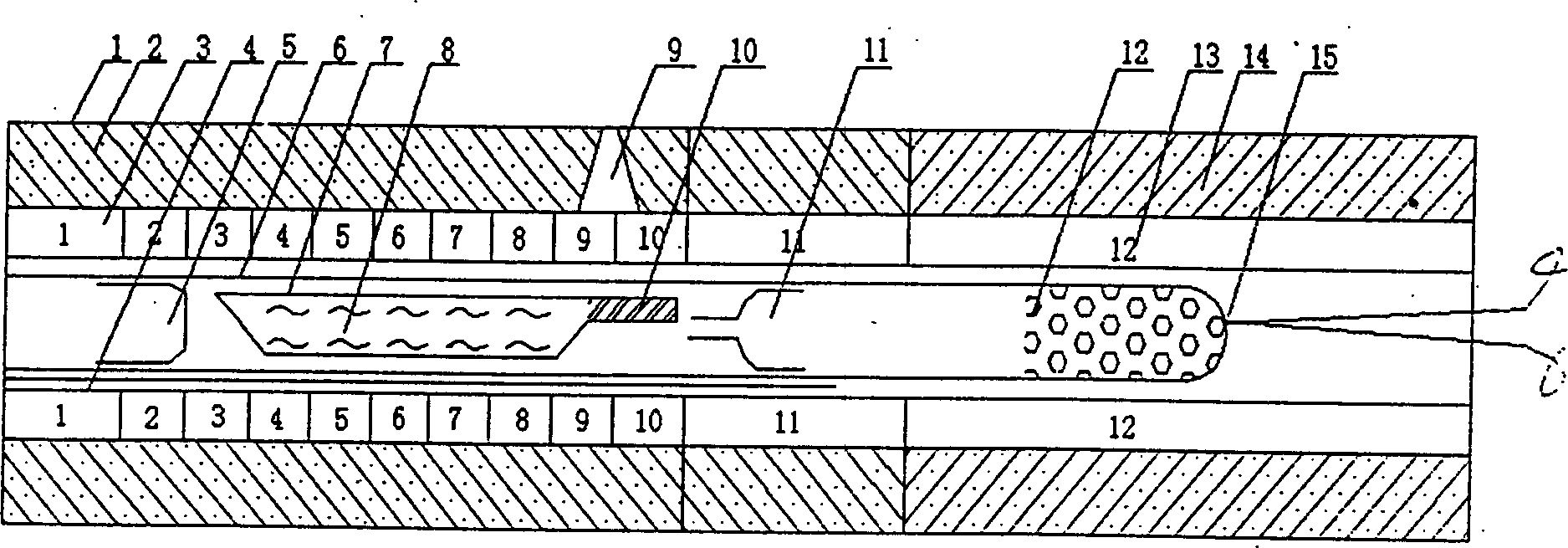

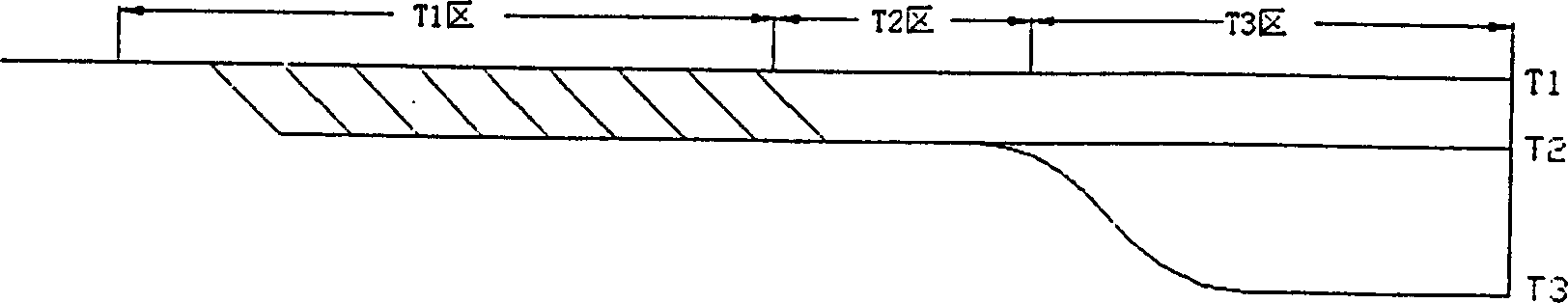

Method used

Image

Examples

example 1

[0040]Example 1: Non-doped high-purity GaAs single crystal growth, the size of the quartz boat is D51×31×300 (width×depth×length), 946g of 6N gallium, and 1037g of 6N arsenic. High-purity GaAs seed crystal 8g. 2.01 kg of non-doped high-purity GaAs single crystal was obtained. The surface and bottom of the crystal ingot are bright without any moisture. Test results, carrier concentration 1.1×10 15 ~2.6×10 15 / cm 3 , Mobility 5200~5860cm 2 / v.s dislocation density 8500 / cm 2 .

example 2

[0041] Example 2: Low-doped Si-GaAs single crystal growth, the size of the quartz boat is D51×31×450 (width×depth×length), 6N gallium 1542.4g, 6N arsenic 1657.6g. Dopant Si48mg. Doped Si-GaAs seed crystal 8g. 3208g doped Si-GaAs single crystal was obtained. The surface and bottom of the crystal ingot are bright without any moisture. Test results, carrier concentration 2.2~8.1×10 17 / cm 3 , mobility 2700~3600cm 2 / v.s dislocation density 6500 / cm 2 .

example 3

[0042] Example 3: Moderately doped Si-GaAs single crystal growth, the inner size of the quartz boat is D51×31×400 (width×depth×length), 1346.8g of 6N gallium, and 1448.8g of 6N arsenic. Dopant Si92mg. Doped Si-GaAs seed crystal 8g. 2793g doped Si-GaAs single crystal was obtained. The surface and bottom of the crystal ingot are bright without any moisture. Test results, carrier concentration 5.3×10 17 ~2.2×10 18 / cm, mobility 1800~2780cm 2 / v.s dislocation density 5200 / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dislocation density | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

| Dislocation density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com