Hydraulic enclosed loading test bench for wheel and axle

A loading test, closed technology, applied in the direction of wheel testing, vehicle testing, machine gear/transmission mechanism testing, etc., can solve the problems of complex and changeable working conditions, large power, large range of working parameters, etc., to achieve gear shifting Flexible and convenient, compact design and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below in conjunction with accompanying drawing:

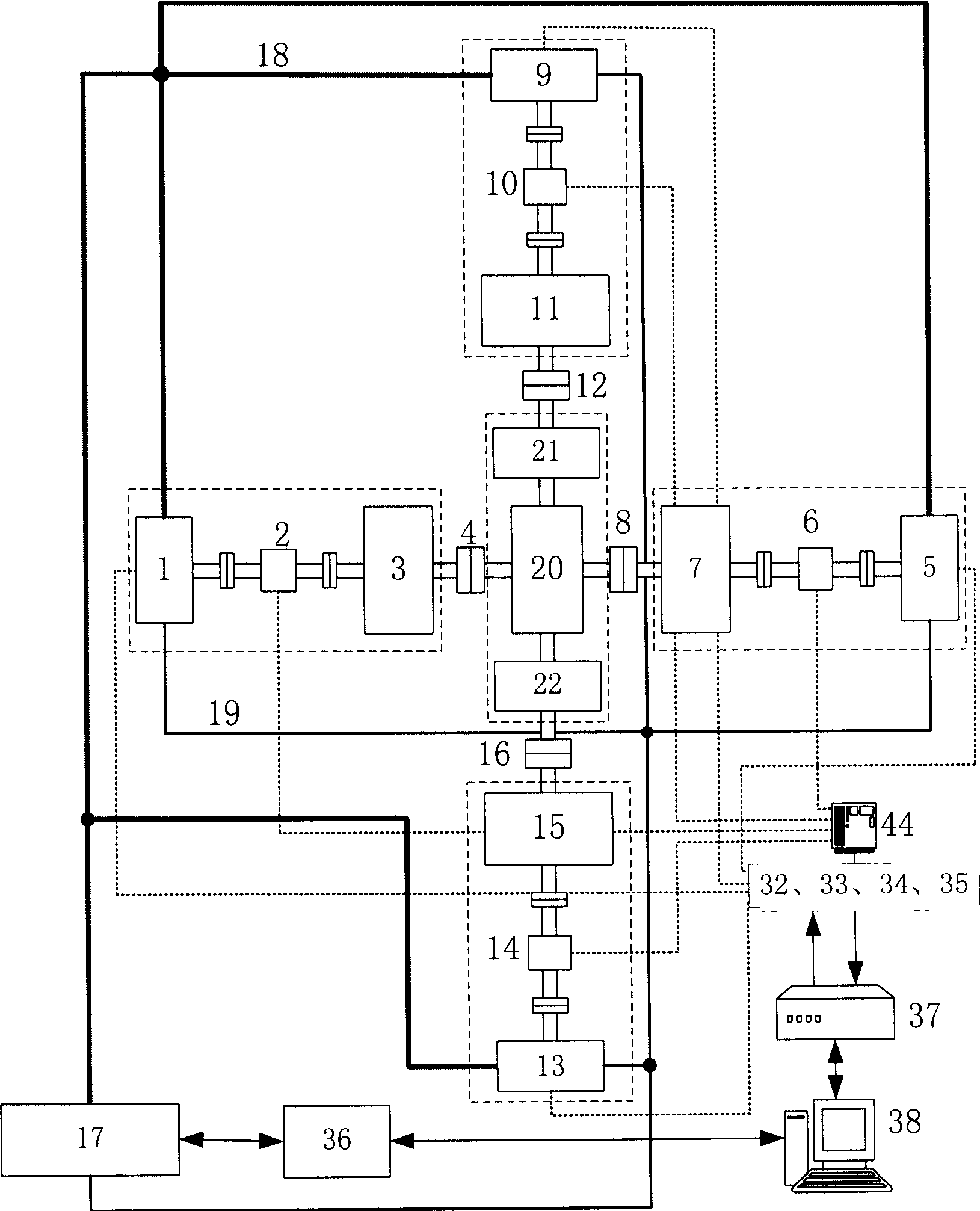

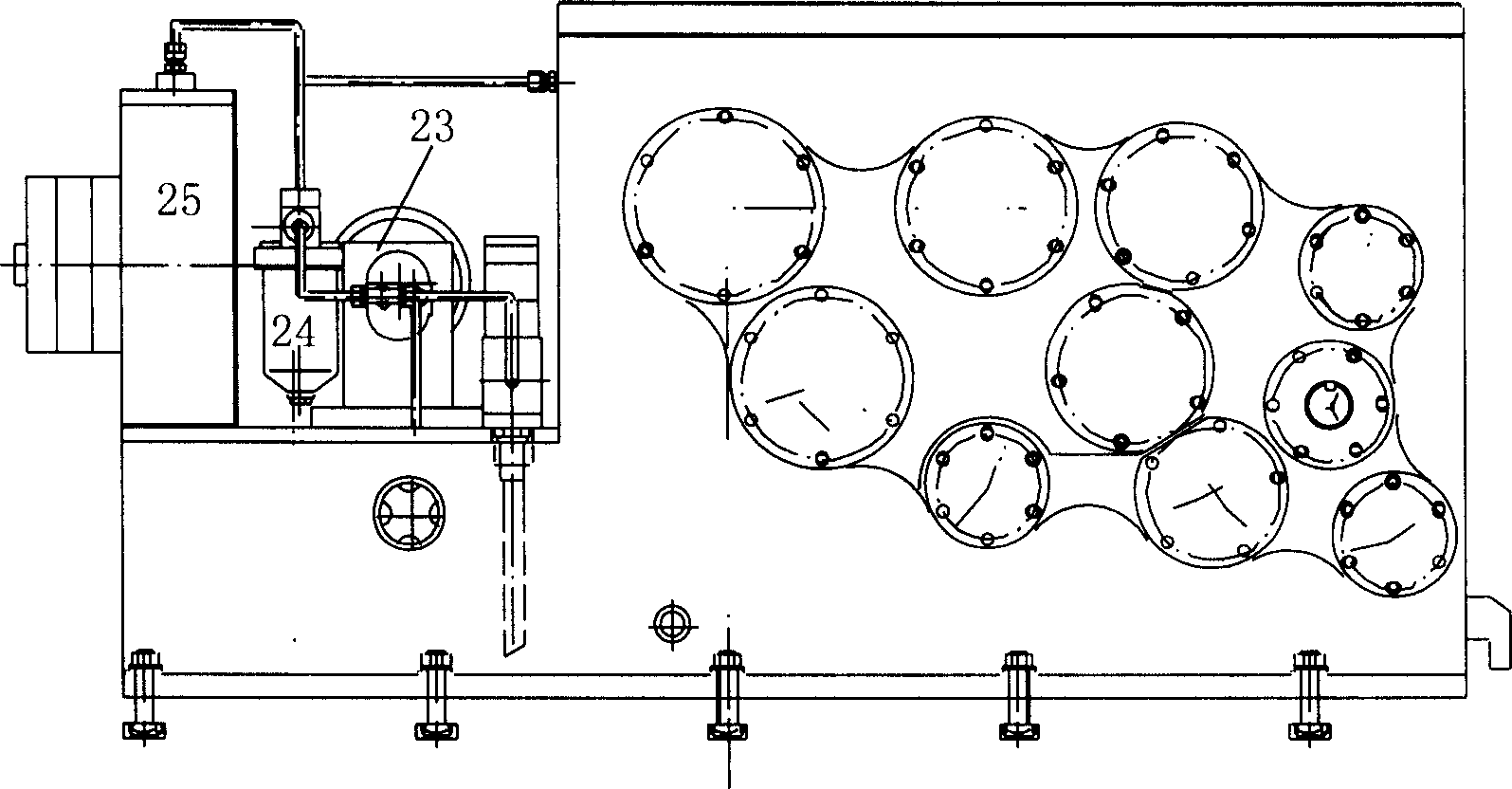

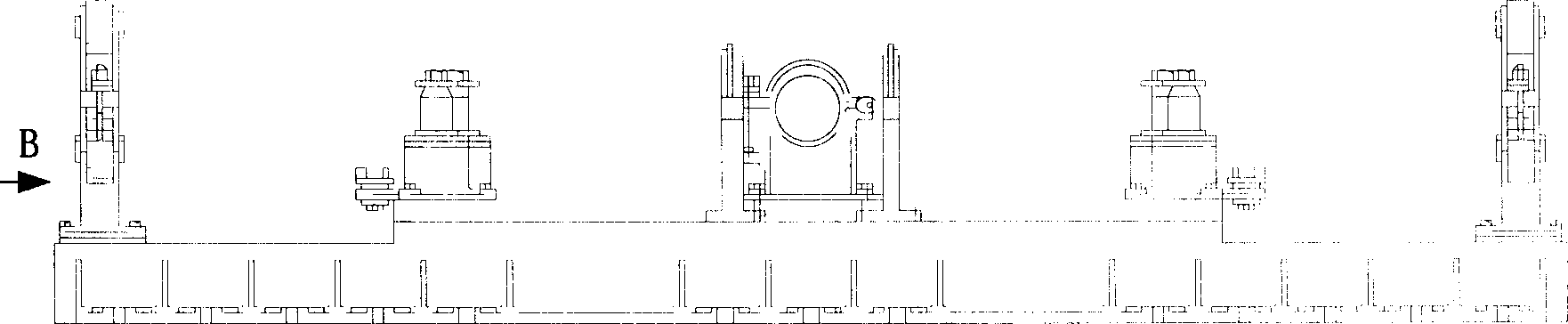

[0022] combine figure 1 , 4 sets of hydraulic ports of secondary components 1, 5, 9 and 13 are connected in parallel to constant pressure networks 18 and 19. The mechanical ports are connected with the tested wheel axles 20, 21, 22 through the rotational speed and torque measuring instruments 2, 6, 10 and 14, the gearboxes 3, 7, 11 and 15, and the connecting shafts 4, 8, 12 and 16. The secondary element 1 works in the motor condition, converts hydraulic energy into mechanical energy, and is used to simulate the driving force of the vehicle engine. It forms a speed control system with the speed torque measuring instrument 2 and the HNC100 controller 32 . The secondary components 5, 9, 13 work in pump conditions, convert mechanical energy into hydraulic energy, and load the three output ports of the tested axle respectively; the same as the corresponding speed torque ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com