Method for decreasing thermal capacitance laser medium thermal stress

A laser medium and thermal stress technology, which is applied in the direction of lasers, laser components, laser components, etc., can solve the problems affecting the increase of laser medium output power, large thermal stress, and affecting the quality of output laser beams, etc., to achieve operability The effect of high stability, thermal stress reduction, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

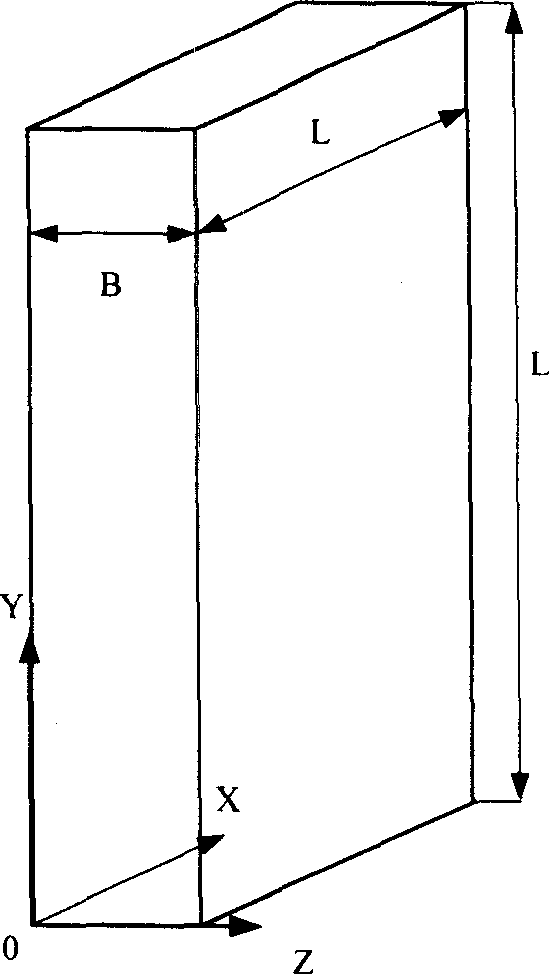

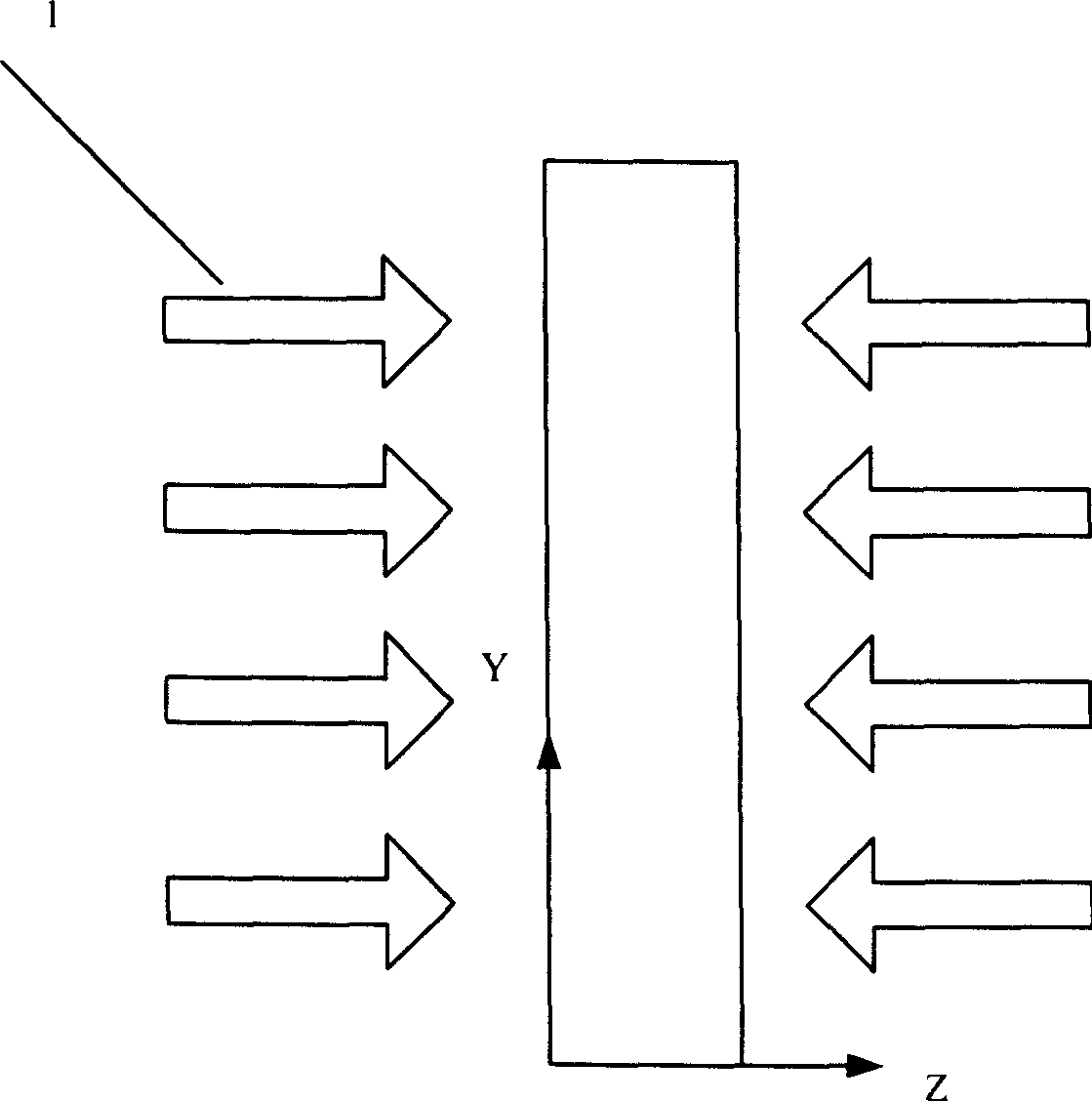

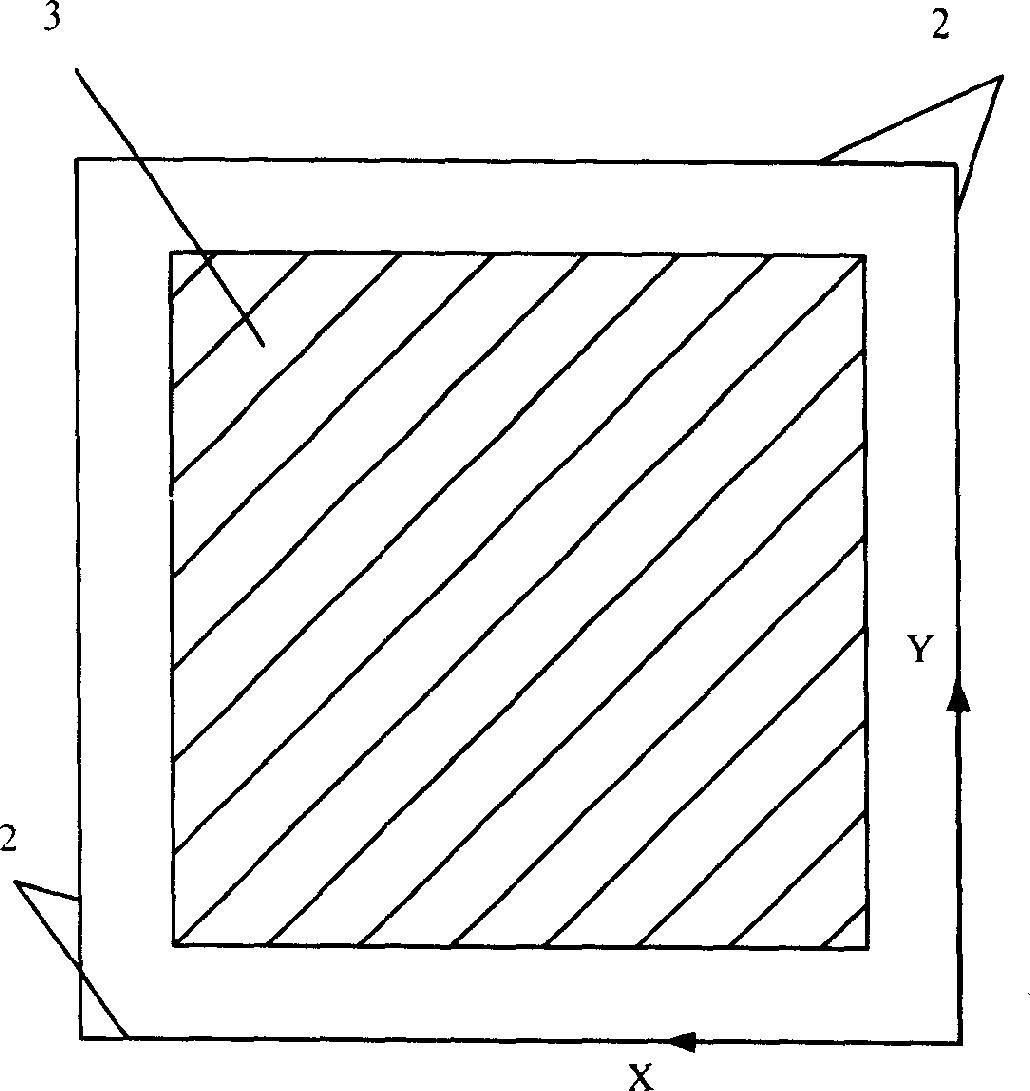

[0030] In a Nd:GGG slab heat capacity laser with double-sided symmetrical uniform pumping, the designed output power is 5KW. There are three dielectric slats in the cavity, and the geometric shape of each slat is as follows: figure 1 , the size is L×L×B=0.06×0.06×0.015m 3 , the laser emission time is designed to be 10s, and the pumping intensity is 1.160MW / m 2 , the initial ambient temperature is 293K. exist figure 2 , image 3 Among them, the uniform pumping light 1 is incident on the two pumping surfaces 3 of the laser medium, the non-pumping surface 2 is insulated, and the area of the pumping surface 3’s light aperture (shaded part) is 0.05×0.05m 2 , the surface of the medium is assumed to be in an adiabatic state. After ANSYS simulation, after 10 seconds of laser emission, the maximum equivalent stress in the slab is 80MPa, which occurs at point (x, y, z: m 3 ): (0, 0.03, 0.0075), (0.03, 0.06, 0.075), (0.06, 0.03, 0.0075), (0.03, 0, 0.0075) four points.

[0031] e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com