Process for preparing high-purity acetylacetone

A technology for the preparation of acetylacetone, which is applied in the field of high-purity acetylacetone preparation technology, can solve the problems of dependence on imports and low purity, and achieve the effects of less equipment investment, high product purity, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

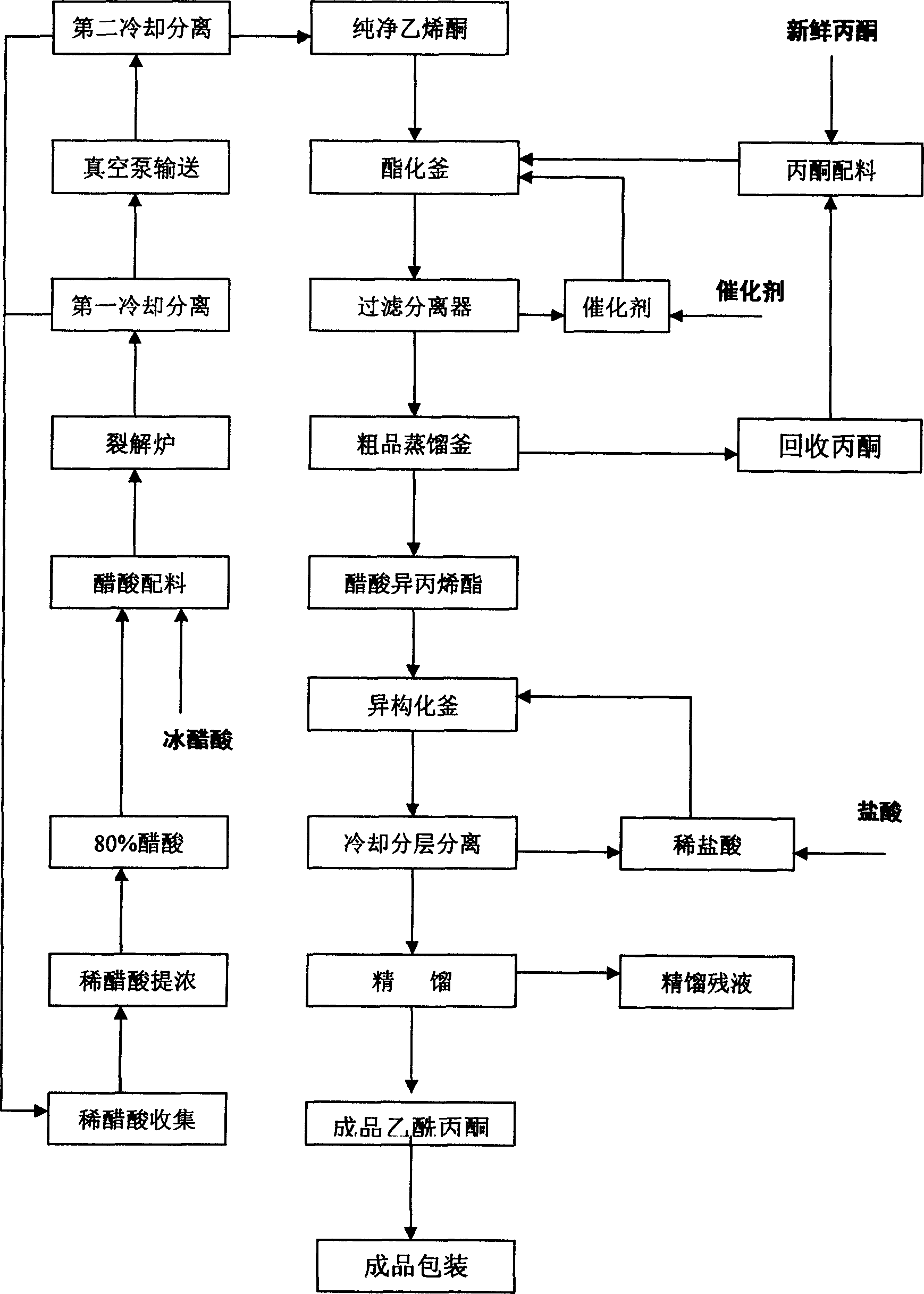

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] Such as figure 1 Shown, the brief description of acetylacetone production process: high-purity acetylacetone preparation process,

[0027] A preparation process containing ketene,

[0028] The first step: the dilute acetic acid from the first cooling separation process and the second cooling separation process is collected through the dilute acetic acid collection process, and then concentrated by 80% through the dilute acetic acid concentration process, and the concentration is 80% acetic acid and 99% ice Acetic acid is formulated into 85% to 95% acetic acid, the 85% to 95% acetic acid is mixed with about 10% by weight triethyl phosphate in a ratio of 10:1, and the mixture passes through a cracking furnace process of 700°C to 1000°C at high temperature Cracking, acetic acid is thermally cracked into acetic acid cracking gas mixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com