Nickel-hydrogen-cell wet net-cutting-pulling negative electrode and preparing technology

A nickel-metal hydride battery and cutting mesh technology, which is applied in the direction of battery electrodes, alkaline battery electrodes, electrode carriers/collectors, etc., can solve the problems of insufficient reaction, easy powder falling, and weak adhesion, etc., to improve energy utilization High efficiency, easy to attach, and reduce the effect of battery chemical reaction polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

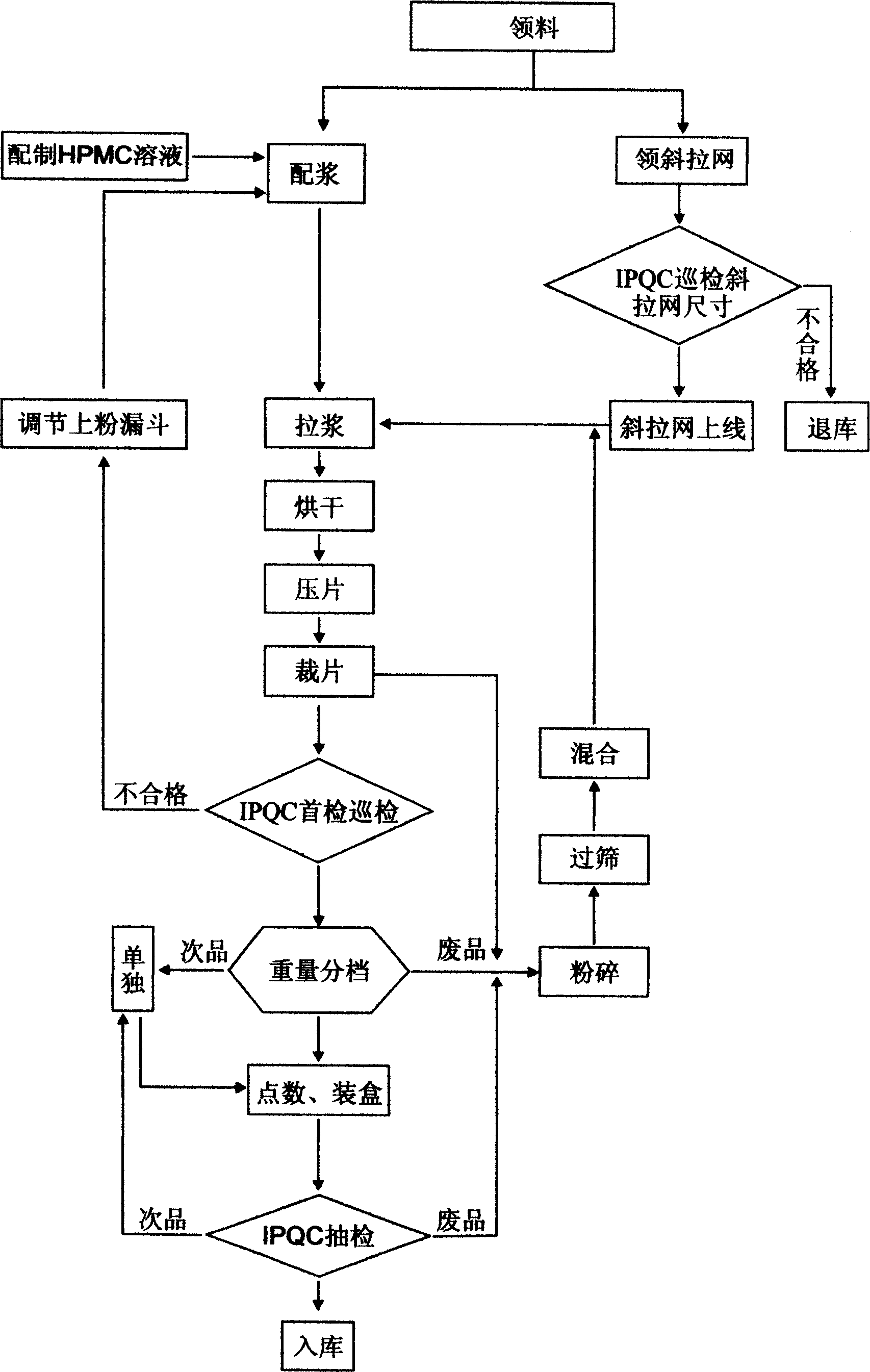

[0042] see figure 1 , the present invention is implemented as follows:

[0043] First, prepare the required raw materials: pure water, HPMC dry powder, AB 5 Lanthanum-rich hydrogen storage alloy powder, carbon black, SBR adhesive and nickel-plated stainless steel cutting wire. Then, according to the following steps, the negative electrode of the nickel-metal hydride battery wet-laid mesh can be prepared.

[0044] 1) Prepare HPMC solution

[0045] First, weigh out the required pure water and HPMC dry powder, heat the pure water to 80±5°C, add HPMC dry powder evenly and a small amount while stirring, and continue stirring until the HPMC dry powder is evenly dissolved; second, weigh and add more pure water to make up for the evaporation of pure water caused by heating; finally, stand for 24 hours at room temperature to obtain a 1.8% HPMC aqueous solution.

[0046] 2) Prepare the slurry

[0047] a) Press AB 5 Lanthanum-rich hydrogen storage alloy powder: carbon black: 1.8% H...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap