Electric heater of re-production of long shutoff thick oil and high viscosity oil well

An electric heater, high pour point oil technology, applied in wellbore/well components, isolation devices, production fluids, etc., can solve the problems of short life, slow heat transfer, and low calorific value of electric heating tubes, and ensure safety. The effect of production, improving production efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

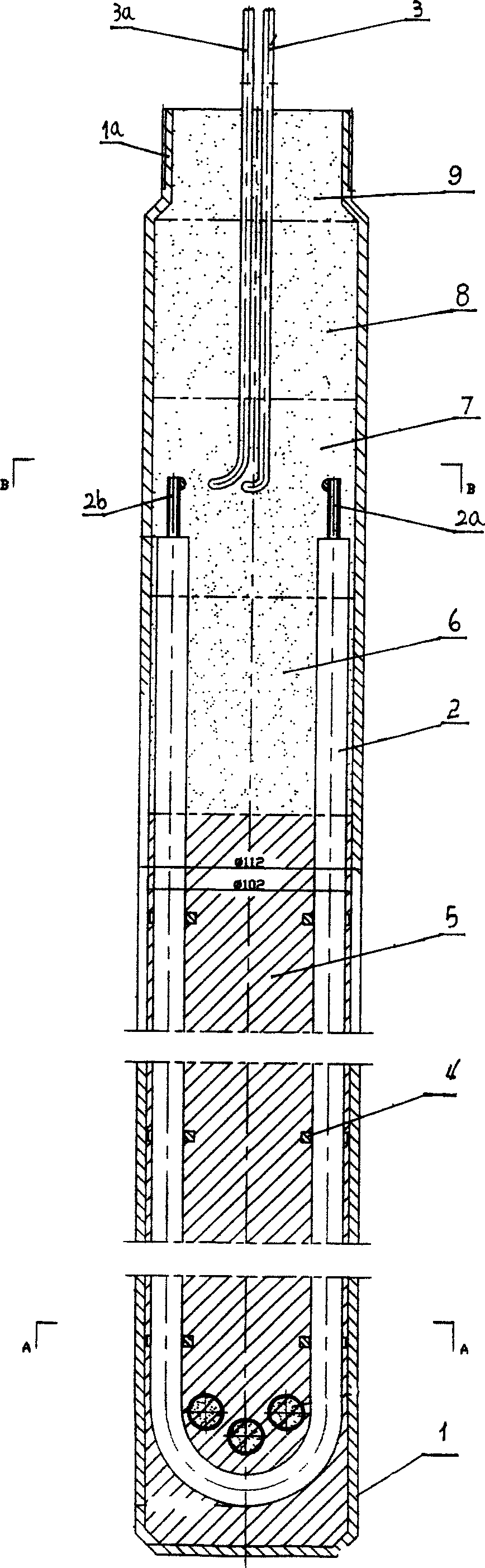

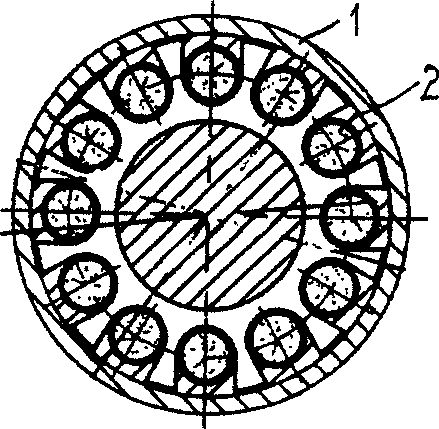

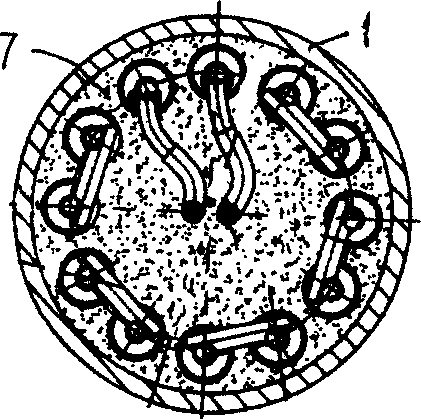

[0022] Embodiment: the inner diameter of the outer shell is 114mm, and the length is 1760mm; a resistance wire is about 3m, and the total length of the resistance wire is more than 18m; Powder layer, 100mm thick epoxy resin layer, 90mm thick magnesium oxide powder layer, 55mm thick epoxy resin layer. The outer casing is made of molybdenum chromium alloy or stainless steel, and the thickness is 3mm. The working voltage is 1800V, the total power is 50kw, and the high-power heating section at the bottom of the outer casing is 500mm long. The design pressure of the present invention is 13Mpa, and the working pressure is 10Mpa. According to the field test in Liaohe Oilfield, the heating of the whole well enema can reach a depth of 475m per minute, that is, it can melt 4.75m deep extra heavy oil per minute.

[0023]The present invention is tested and the use report that is made by probationary unit (Liaohe Petroleum Exploration Bureau Engineering Technology Research Institute Down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com