Preparation of biological degradation resin composite and modified special resin and product forming process

A biodegradable resin and molding processing technology, which is applied in the field of biodegradable resin compounding and modified special resin preparation and molding technology, can solve the problems of performance difference, complex preparation process of processing and molding equipment, and high price, so as to achieve low cost and enhanced Rigid, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Biodegradable resin composite and modified injection molding special resin A# formula consists of the following components in weight percentage: PBS 40%, PLA 10%, modified starch 30%, activated inorganic filler 19.85% and additives 0.15%.

Embodiment 2

[0044] Example 2: biodegradable resin composite and modified injection molding special resin B# formula consists of the following components in weight percent: PBS 25%, PLA 25%, modified starch 35%, activated inorganic filler 14.75% and additives 0.25%.

Embodiment 3

[0045] Example 3: biodegradable resin composite and modified injection molding special resin C# formula consists of the following components by weight percentage: PBS 10%, PLA 60%, activated inorganic filler 29.5%, additive additive 0.5%.

PUM

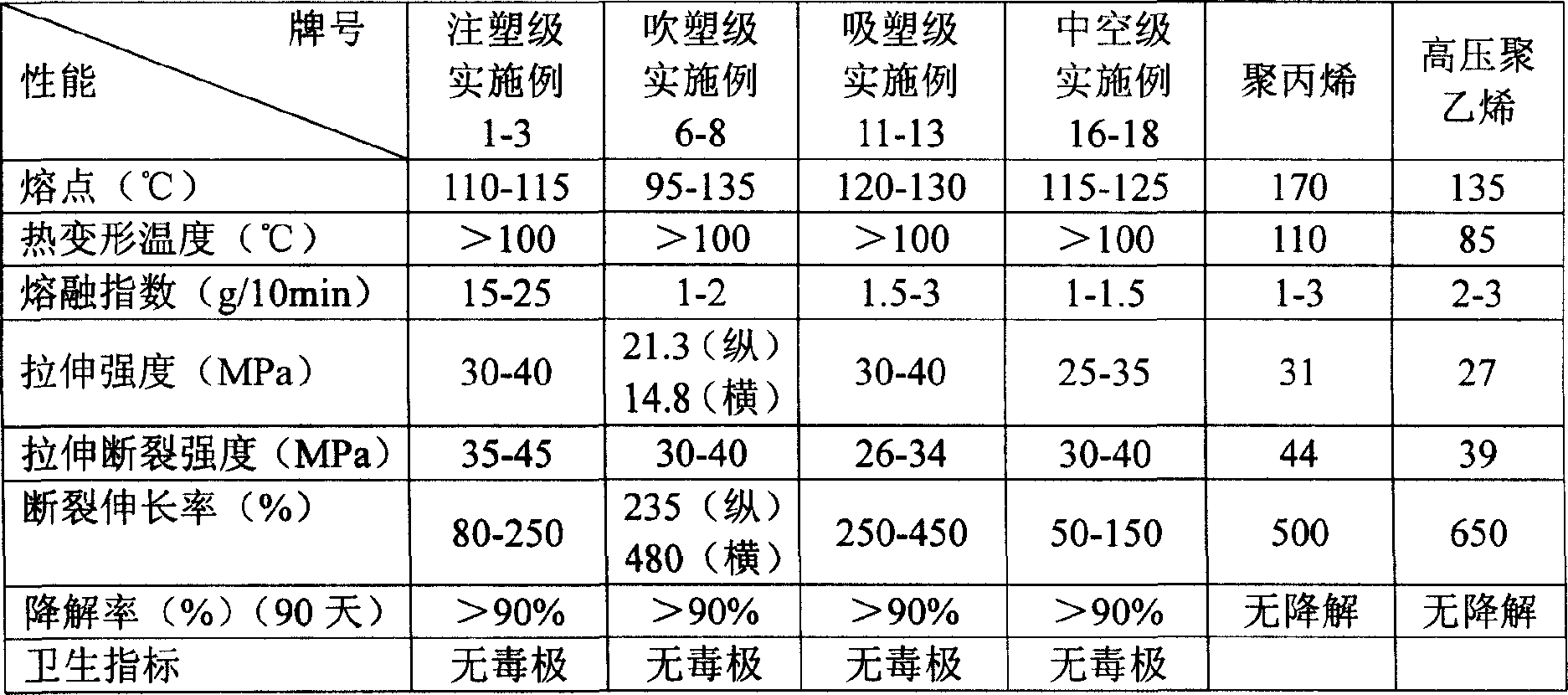

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com