Thermal-insulating waterproof spray-coating building envelope structure

A technology for buildings and structures, applied in building structures, building insulation materials, building components, etc., can solve problems such as failure of insulation materials, rising production costs, condensation, etc., to achieve sound insulation and noise reduction service life, protection Service life, effect of protecting the main body of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

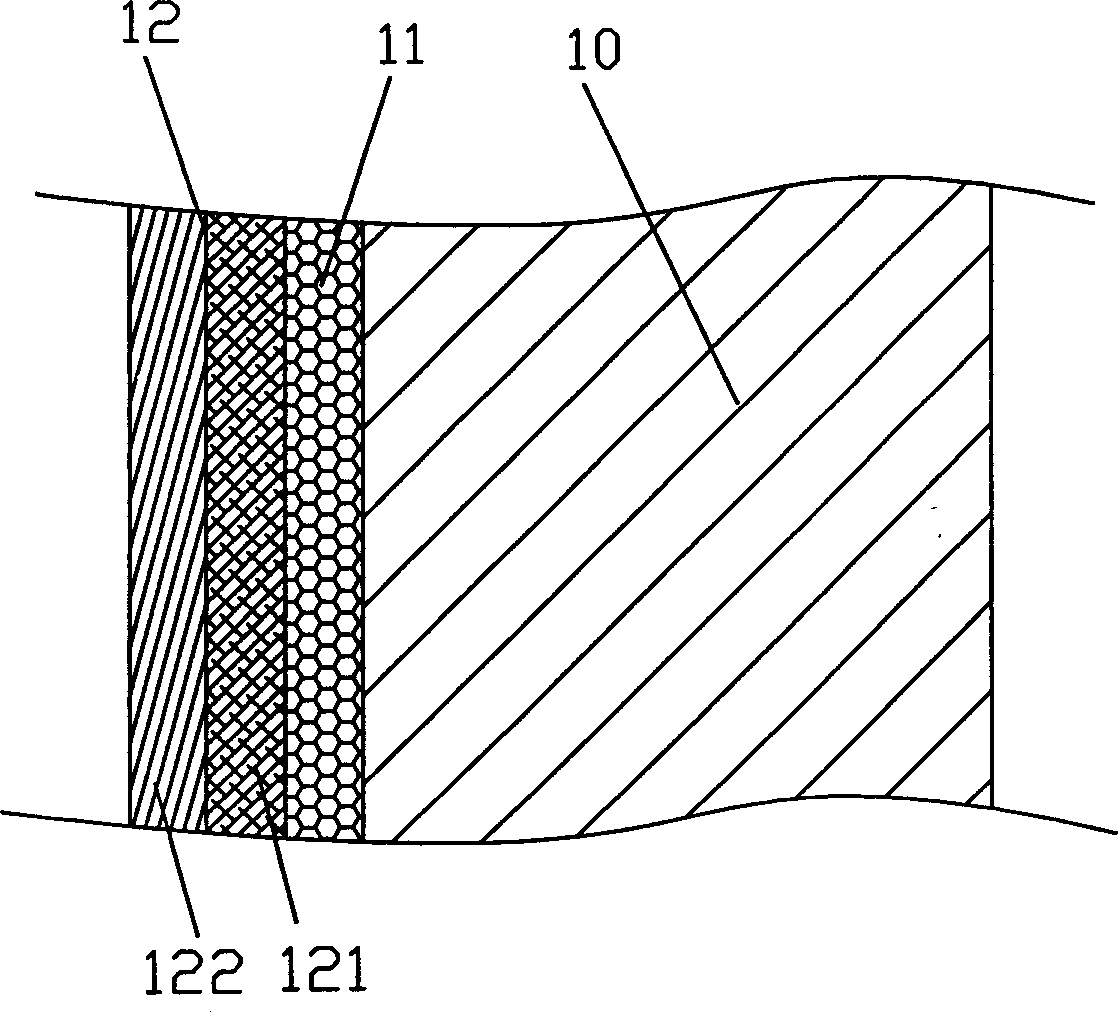

[0076] Embodiment one, see figure 1 As shown, the thermal insulation and waterproof spray coating enclosure structure of a building of the present invention is composed of the thermal insulation and waterproof layer 11 directly sprayed on the outside of the building main structure 10 and the protective layer 12 made on the thermal insulation and waterproof layer 11.

[0077] The thermal insulation and waterproof layer 11 is formed by spraying the thermal insulation and waterproof liquid material directly on the working surface of the main structure of the building once through foaming equipment and foaming; the thermal insulation and waterproof liquid material is composed of the following components and parts by weight: polyfunctional polyether polyol, poly Ester polyol mixture 65, alcohol, sugar as starter polyether polyol 30, ethylenediamine as starter polyether polyol 0.05, flame retardant 13, foam leveling agent 3, foaming agent 30, cycloethylamine 3. Potassium acetate 2.5...

Embodiment 2

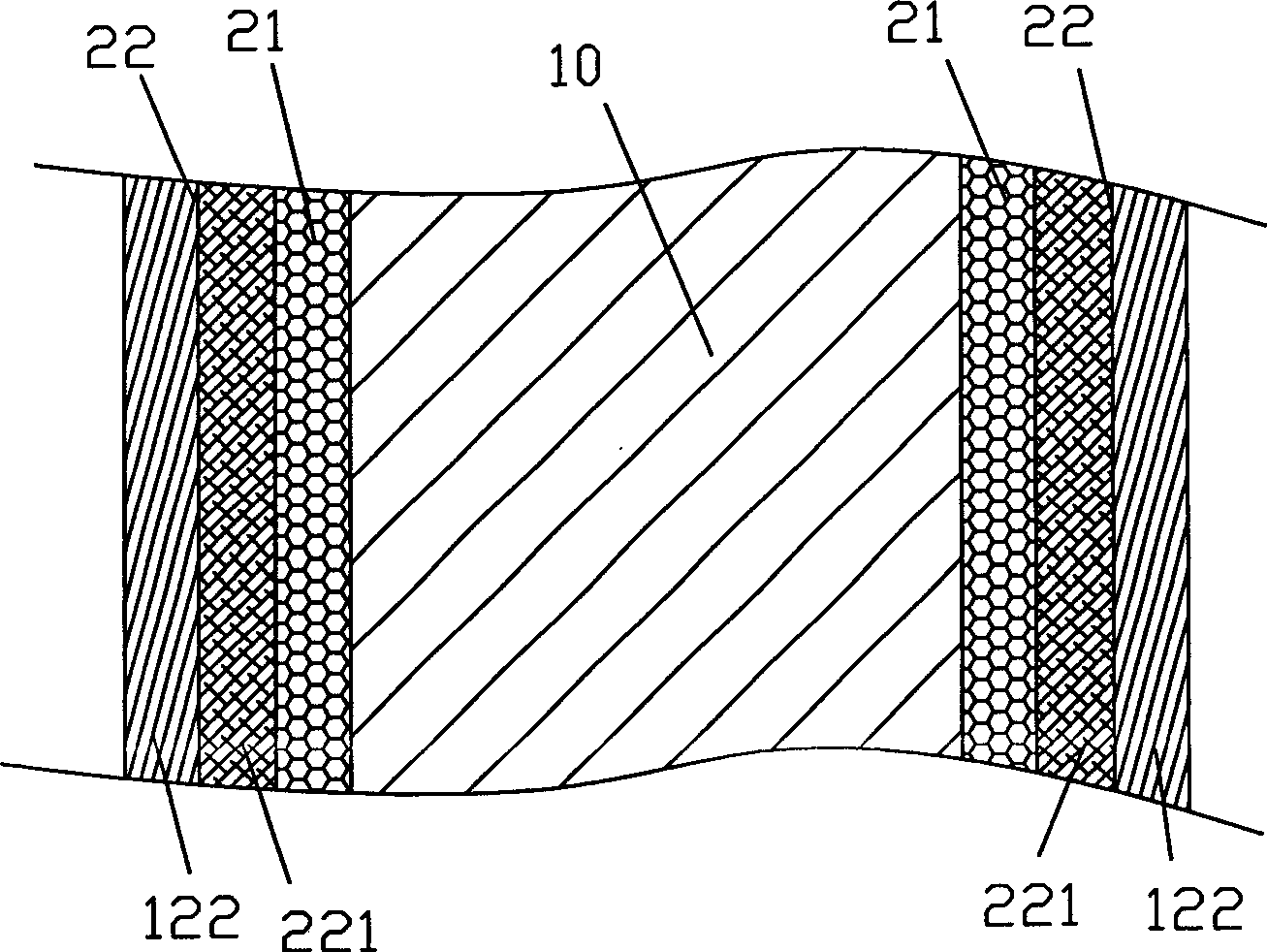

[0081] Embodiment two, see figure 2 As shown, the thermal insulation and waterproof spray coating enclosure structure of a building of the present invention consists of a thermal insulation and waterproof layer 21 sprayed directly on the main structure of the building 10 and a protective layer 22 made on the thermal insulation and waterproof layer 21.

[0082] The protective layer 22 is an ordinary protective layer; the ordinary protective layer is composed of a transition layer 221 directly sprayed or wiped on the thermal insulation and waterproof layer 21 and an anti-crack mortar layer 122 wiped on the transition layer;

[0083] The difference with Embodiment 1 is that the thermal insulation and waterproof layer 21 is not only sprayed on the outside of the main structure of the building 10, but also the thermal insulation and waterproof layer 21 is sprayed on the inside of the main structure of the building 10, and the inner and outer thermal insulation and waterproof layers...

Embodiment 3

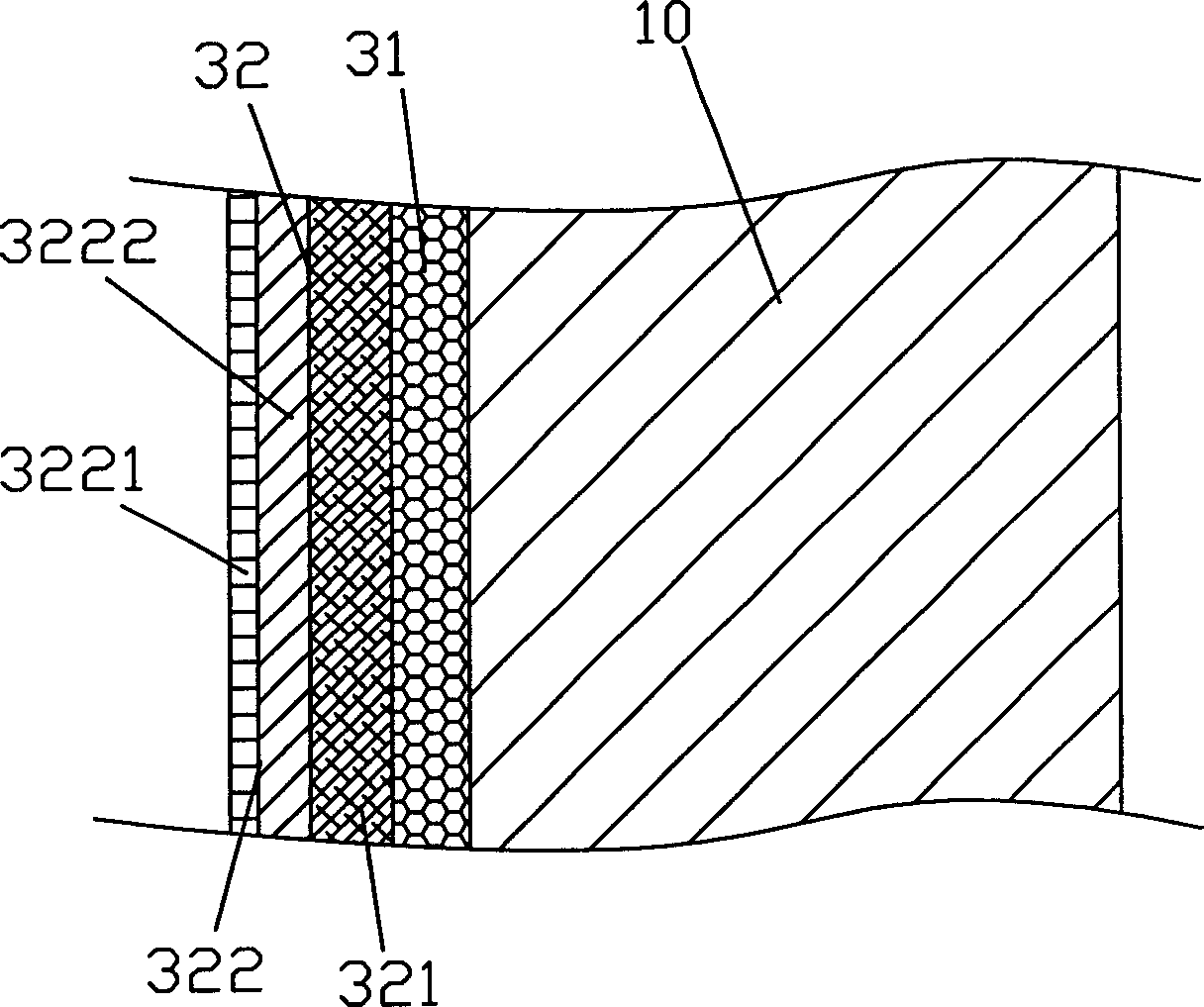

[0085] Embodiment three, see image 3 As shown, a thermal insulation and waterproof spray coating enclosure structure of a building of the present invention consists of a thermal insulation and waterproof layer 31 directly sprayed on the outside of the building main structure 10 and a protective layer 32 made on the thermal insulation and waterproof layer 31.

[0086] The difference from Embodiment 1 is that the protective layer 32 is a reinforced protective layer; the reinforced protective layer is composed of a transition layer 321 directly sprayed or wiped on the thermal insulation and waterproof layer 31 and a mosaic layer 322 pasted on the transition layer and the thermal insulation and waterproof liquid material of thermal insulation and waterproof layer 31 is made up of following components and parts by weight: multifunctionality polyether polyol, polyester polyol mixture 73, alcohol, sugar are starter polyether polyol 9, ethylene glycol Amine is the initiator polyether...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com