Temperature control system and method for power battery pack of electric vehicle

A technology for power battery packs and electric vehicles, applied in electric power devices, control/regulation systems, non-electric variable control, etc. Battery life, improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

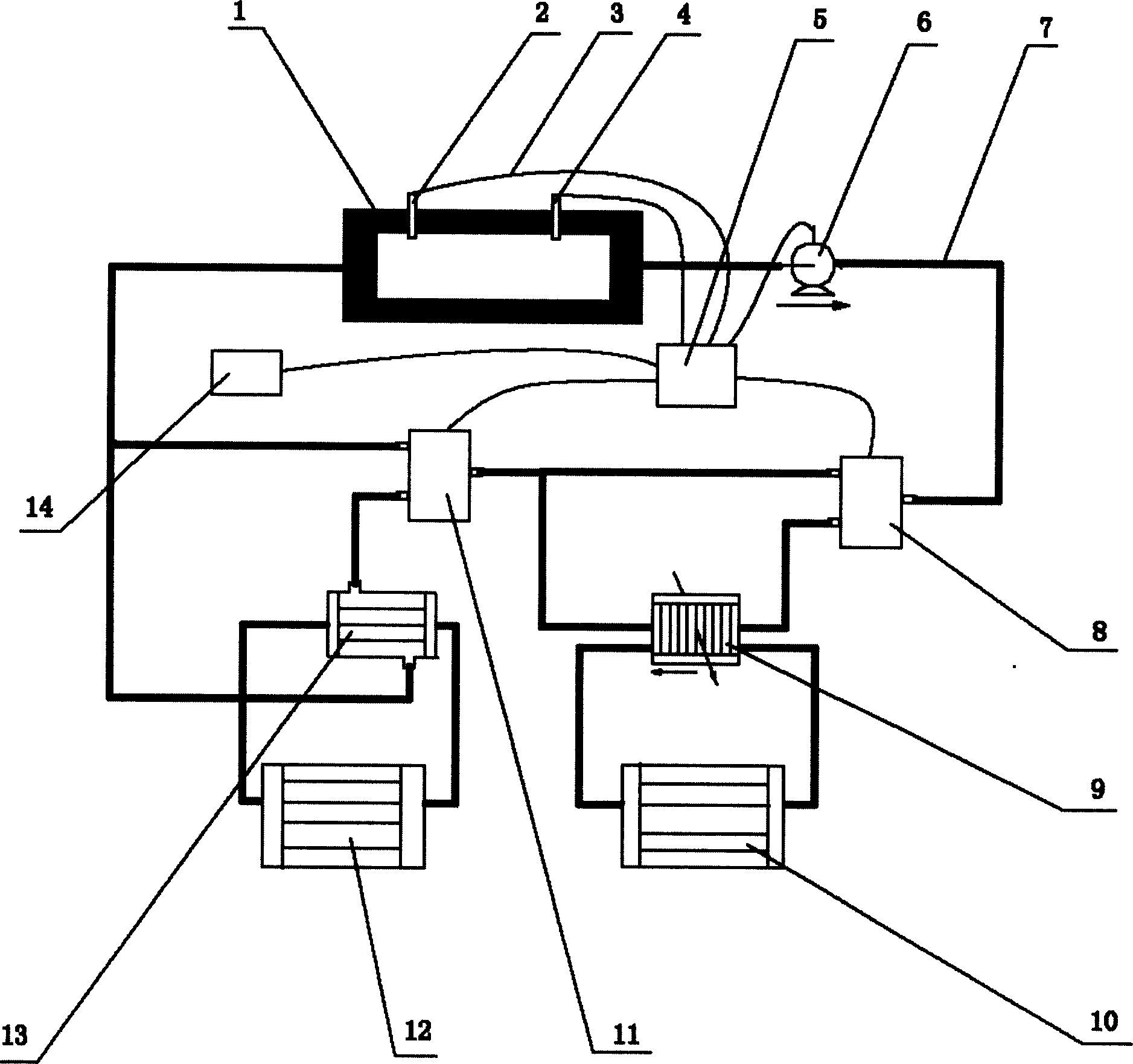

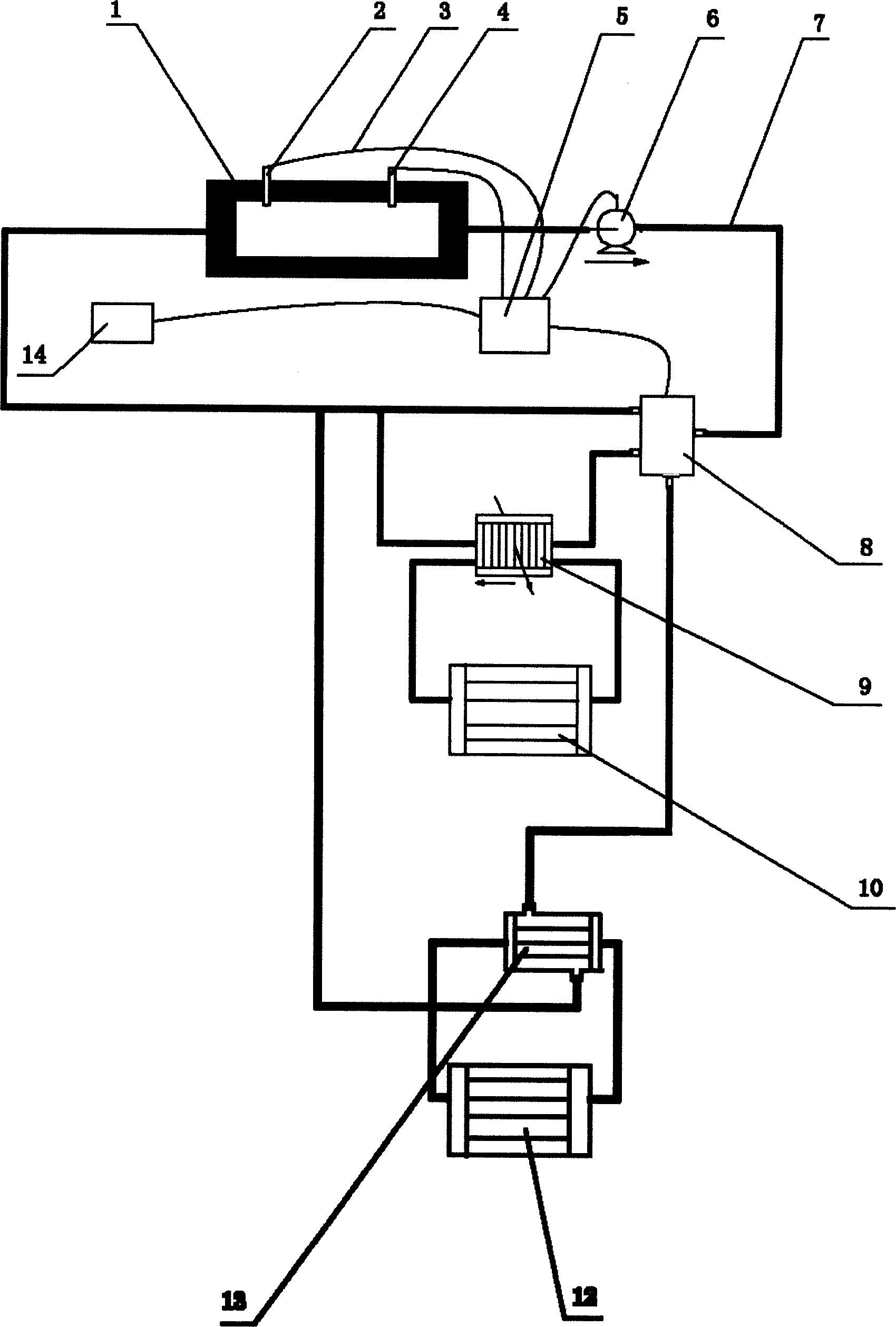

[0017] Such as figure 1 As shown, an embodiment of the present invention includes: power battery pack 1, temperature sensor 2, signal line 3, redundant temperature sensor 4, electronic control unit 5, hydraulic pump 6, circulation pipeline 7, electromagnetic directional valve 8, steam / liquid Heat exchanger 9, vehicle air conditioning system 10, electromagnetic directional valve 11, drive motor cooling system 12, liquid / liquid heat exchanger 13, power battery current signal sensor 14.

[0018] The outlet circulation pipeline 7 of the power battery pack 1 is connected to the electromagnetic directional valve 8, the normal temperature outlet of the electromagnetic directional valve 8 is directly connected to the inlet of the electromagnetic directional valve 11 through a pipeline, and the low temperature outlet is connected to the steam / liquid heat exchanger 9 through a pipeline. Liquid inlet, the liquid outlet of the heat exchanger is connected to the inlet of the electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com