Gas power circulation system and circulation method

A circulatory system and power cycle technology, applied to combustion engines, gas turbine devices, internal combustion piston engines, etc., can solve problems such as limited power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

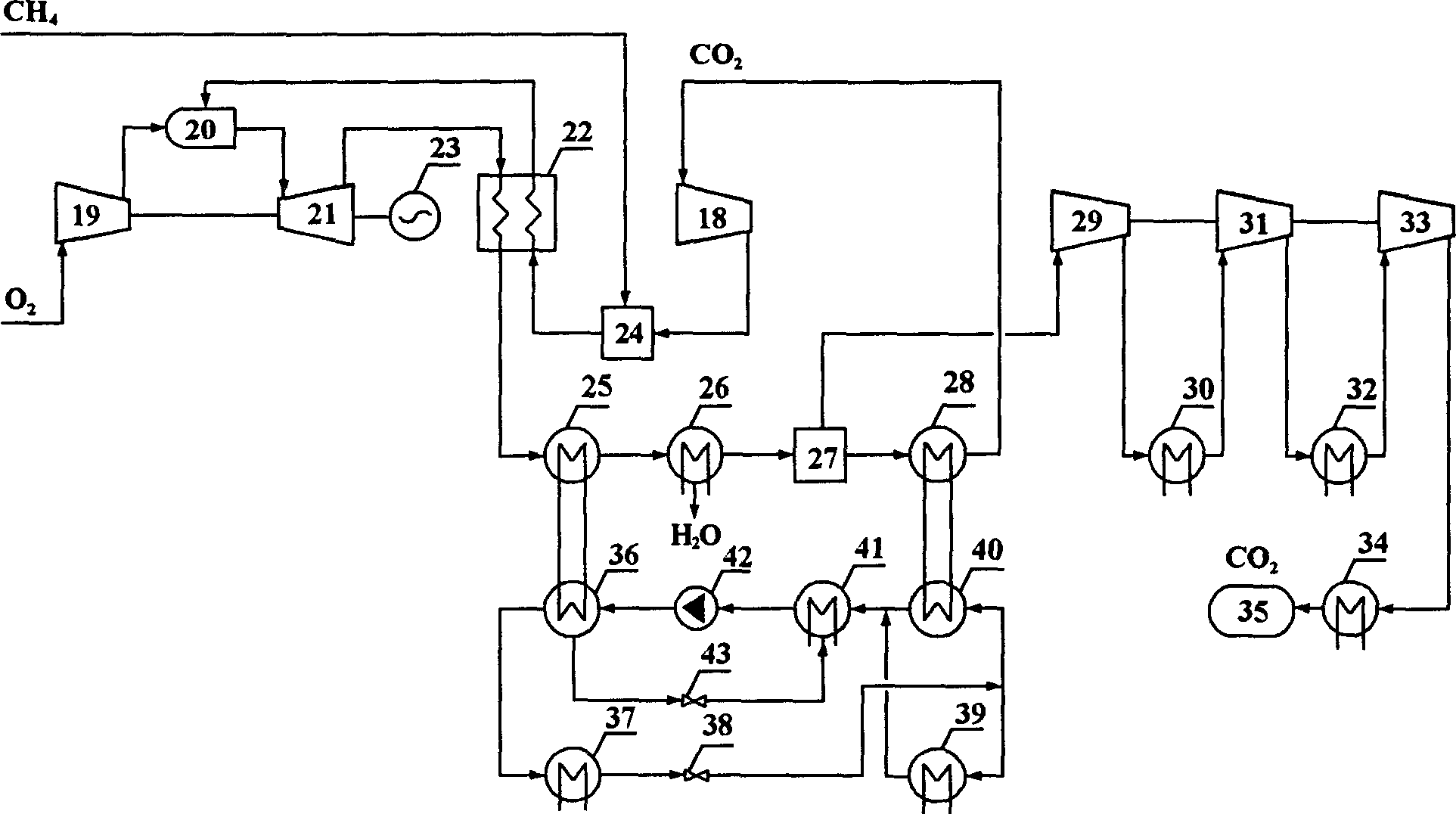

[0015] Such as figure 2 Shown: the system of the present invention consists of O 2 / CO 2 Combination of chemical heat recovery power cycle and ammonia absorption refrigeration cycle. The specific implementation is as follows:

[0016] With natural gas as fuel, with CO 2 As the circulating working fluid, the CO cooled by the cooler 28 2 Pressurized by the compressor 18, mixed with the natural gas from the natural gas pipeline in the mixer 24, enters the reforming reactor 22 to undergo a reforming reaction, the reforming reaction gas reacts with oxygen according to the stoichiometric number, and the reforming reaction equation is: ; , the reformed product generates H 2 and CO, then enter the combustion chamber 20, and undergo a combustion reaction with the pure oxygen pressurized by the compressor 19, and the combustion reaction equation is: ; ; , the generated high-temperature gas expands in the turbine 21 to do work. The turbine exhaust first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com