Grinding tool with single layer of diamond, and manufacturing method

A technology for grinding tools and manufacturing methods, applied in grinding devices, manufacturing tools, metal processing equipment, etc., can solve the problem of reducing the exposed height of abrasive particles and the chip space, affecting the grinding speed and quality, and the absence of strong chemical Combined with other problems, to achieve more regular arrangement, improve production efficiency, reduce supplementation or adjust the proportion of abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

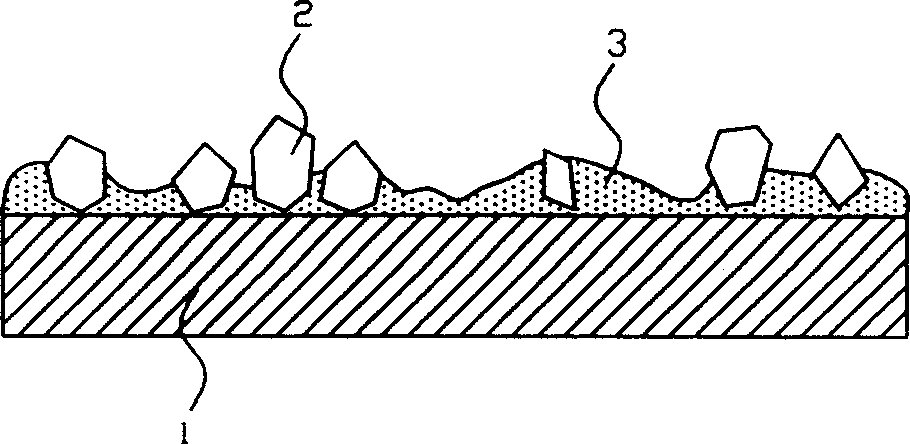

Problems solved by technology

Method used

Image

Examples

Embodiment 1

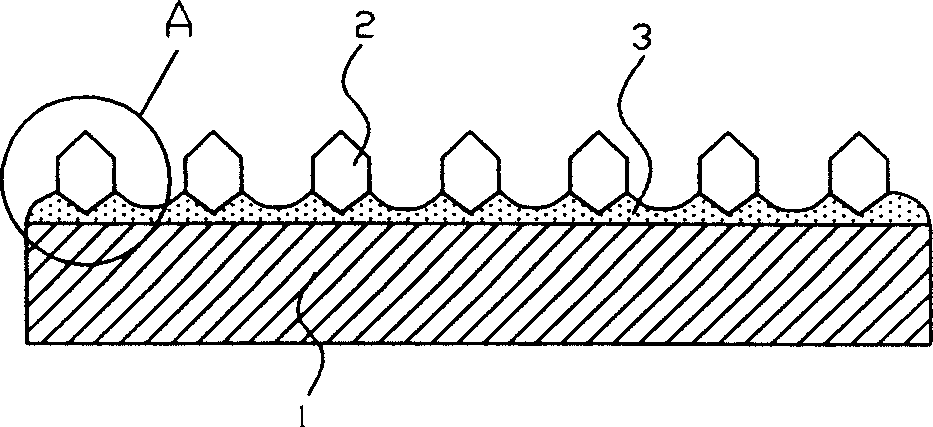

[0039] refer to figure 2 , Figure 4 , Figure 10 , a single-layer diamond grinding disc without an anti-corrosion layer, the diamond abrasive particles 2 are fixed on the substrate 1 through the brazing layer 3, a layer of titanium carbide layer 21 is formed between the diamond abrasive particles 2 and the brazing layer 3, and the diamond abrasive particles 2 Arranged in an equilateral triangle, the exposed height is about 80% of the abrasive grains 2 . The diamond abrasive particles 2 are diamond sand with a size of about 200 microns, and the brazing layer 3 is a copper alloy containing 11% by weight of titanium.

[0040] The grinding disc has good sharpness, good grinding effect and large chip capacity, and the service life of the tool is 1.5 to 2 times that of the existing tools.

[0041] refer to Figure 5 to Figure 9 , its manufacturing process includes the following steps:

[0042] 1. Apply an adhesive layer 6 on the surface of the substrate 1 after cleaning and s...

Embodiment 2

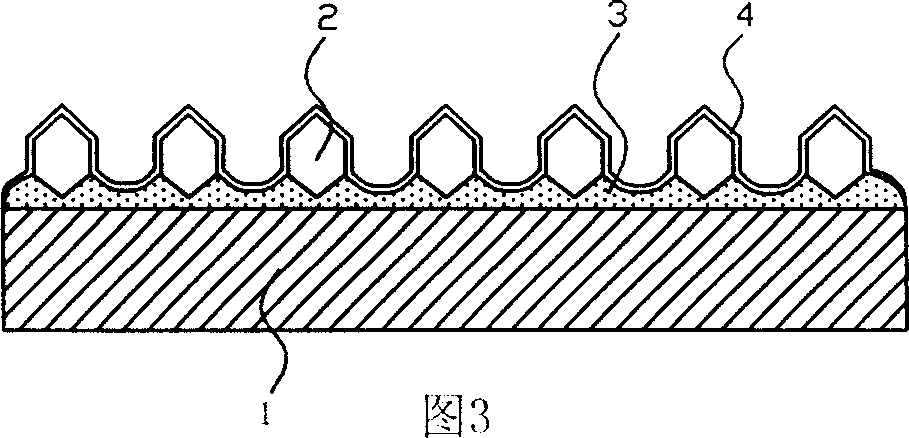

[0047] With reference to Fig. 3, make single-layer diamond grinding tool according to the method for embodiment one, cover one deck anti-corrosion layer 4 on diamond abrasive particles 2 and brazing layer 3, anti-corrosion layer 4 is ceramic glaze, and its thickness is 2 μ m, adopts Made by Physical Vapor Deposition. The service life of the tool in the acidic environment is more than 2.5 times that of the existing grinding tools.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com