Method for producing potassium chloride crystal through solarization on large area of brine pan

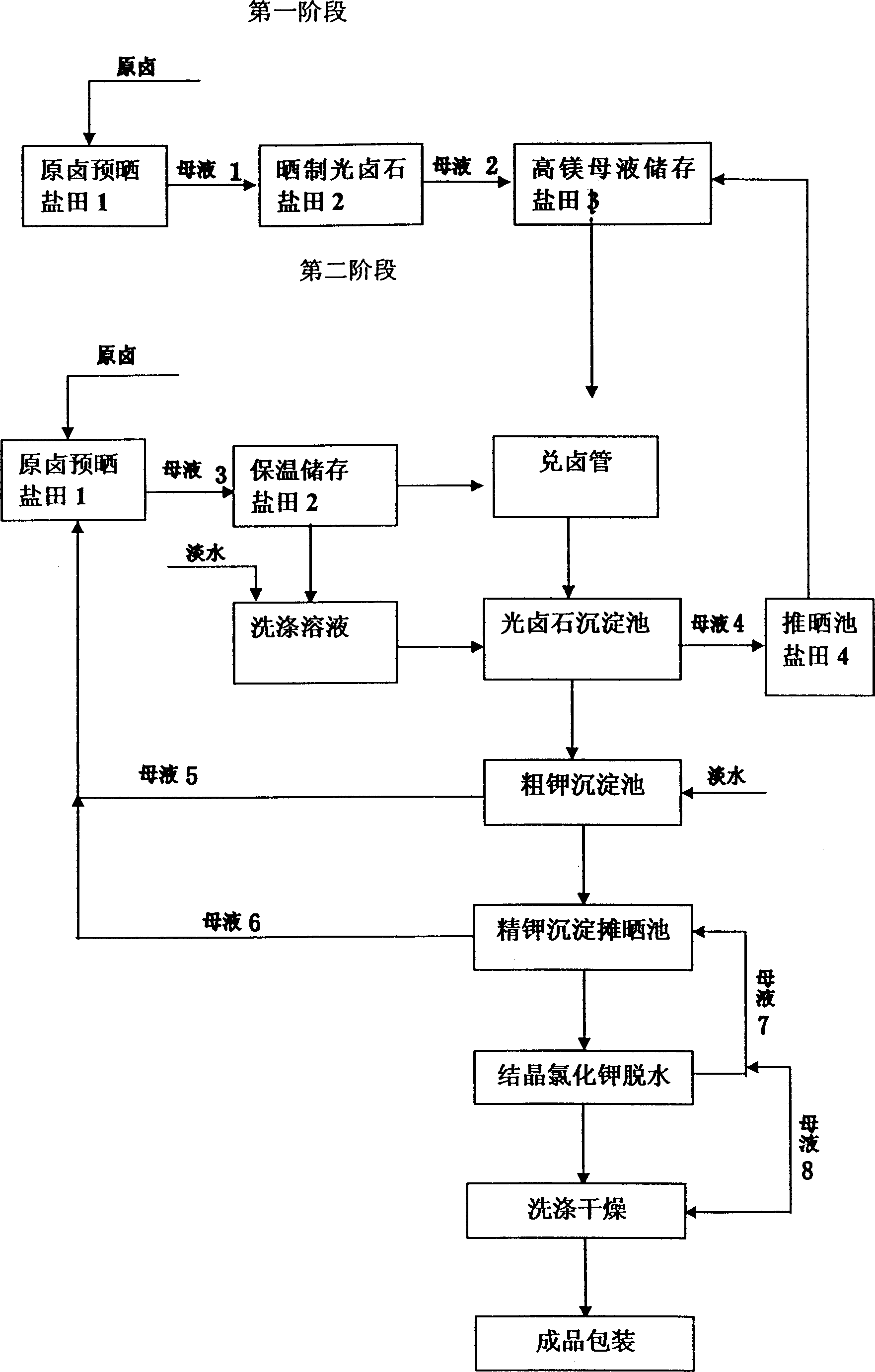

A potassium chloride, large-area technology, applied in the direction of alkali metal chloride, energy input, etc., can solve the problems of adding chemical agents, lengthy process, low recovery rate, etc., and achieve high recovery rate, uniform grade, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Embodiment (mother liquor is not recovered)

[0041] At 25 DEG C, according to the aforementioned method, take by weighing 1116 kg of potassium-containing chloride-type brine with a Pomi concentration of 29Be, pre-dry to a magnesium chloride content of 26%, and obtain a solution of 836 kg, then mix it with a high-magnesium mother solution with a Pomei concentration of 35Be. The ratio of 1 to 2 is mixed and blended, and the precipitation is clarified to obtain 58kg of carnallite with a potassium chloride content of 23%. Potassium content is 56% crude potassium chloride 14kg, then washes with 34Kg fresh water, spreads and obtains content and is 93% crystalline potassium chloride 5.9kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com