Revolving internal-combustion engine

一种内燃机、旋转式的技术,应用在旋转活塞式发动机、内燃活塞发动机、旋转或摆动活塞发动机等方向,能够解决增加摩擦功率的损失和密封、加大动负荷和轴承磨损、消耗功率等问题,达到重量和体积减少、节约制造成本、简化制造程序的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

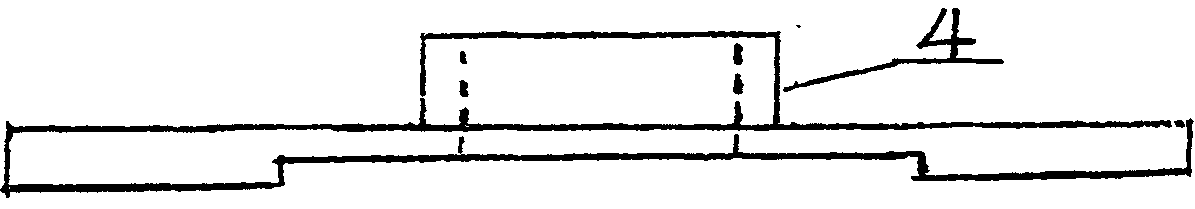

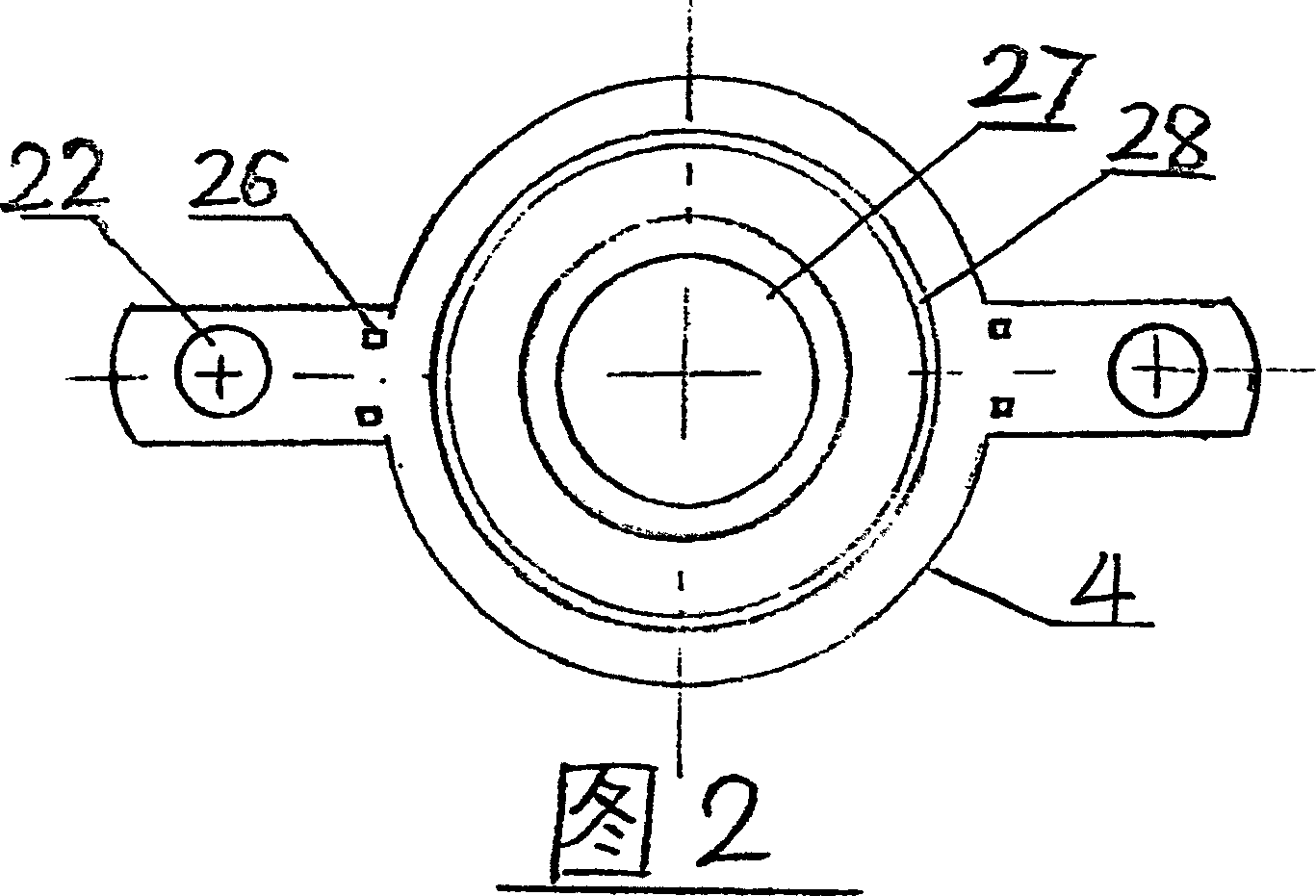

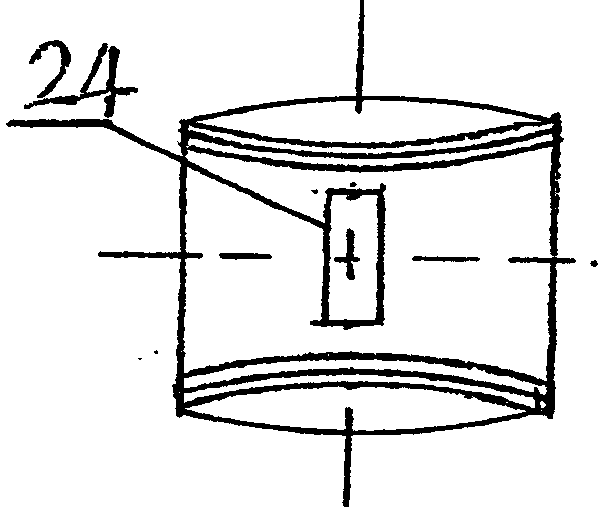

[0029] This structure consists of two identical semicircular annular cylinders 2, 12 (such as Image 6 (Shown) to form an annular cylinder with a circular cross section, such as Image 6 , 7 , 9 shows; inside it is equipped with two identical rotors 4, 5, such as figure 1 , 2, 9; the two sides of the rotor 4, 5 and the corresponding parts of the cylinder are provided with a sealing ring groove 28, as shown in Figures 2, 6, 7, and 9; the groove is equipped with a sealing ring (not shown in the figure) ); There are four identical pistons 3 respectively fixed on the two ends of the two rotors 4, 5, the hole 24 on the piston is installed on the rotor end, the piston pin hole 23 on the piston and the piston pin hole on the rotor end 22 concentric, as shown in Figures 2, 3, 4, and 5; fixed with the same piston pin or bolt as on the reciproca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com