Induction heating device

An electromagnetic induction heating and heating coil technology, applied in the direction of induction heating device, induction heating, induction heating control, etc., can solve the loss of magnetic cooking utensils, the deterioration of noise characteristics, the great change of the open circuit current of semiconductor switching elements, and the non-magnetic Deterioration of cooking utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

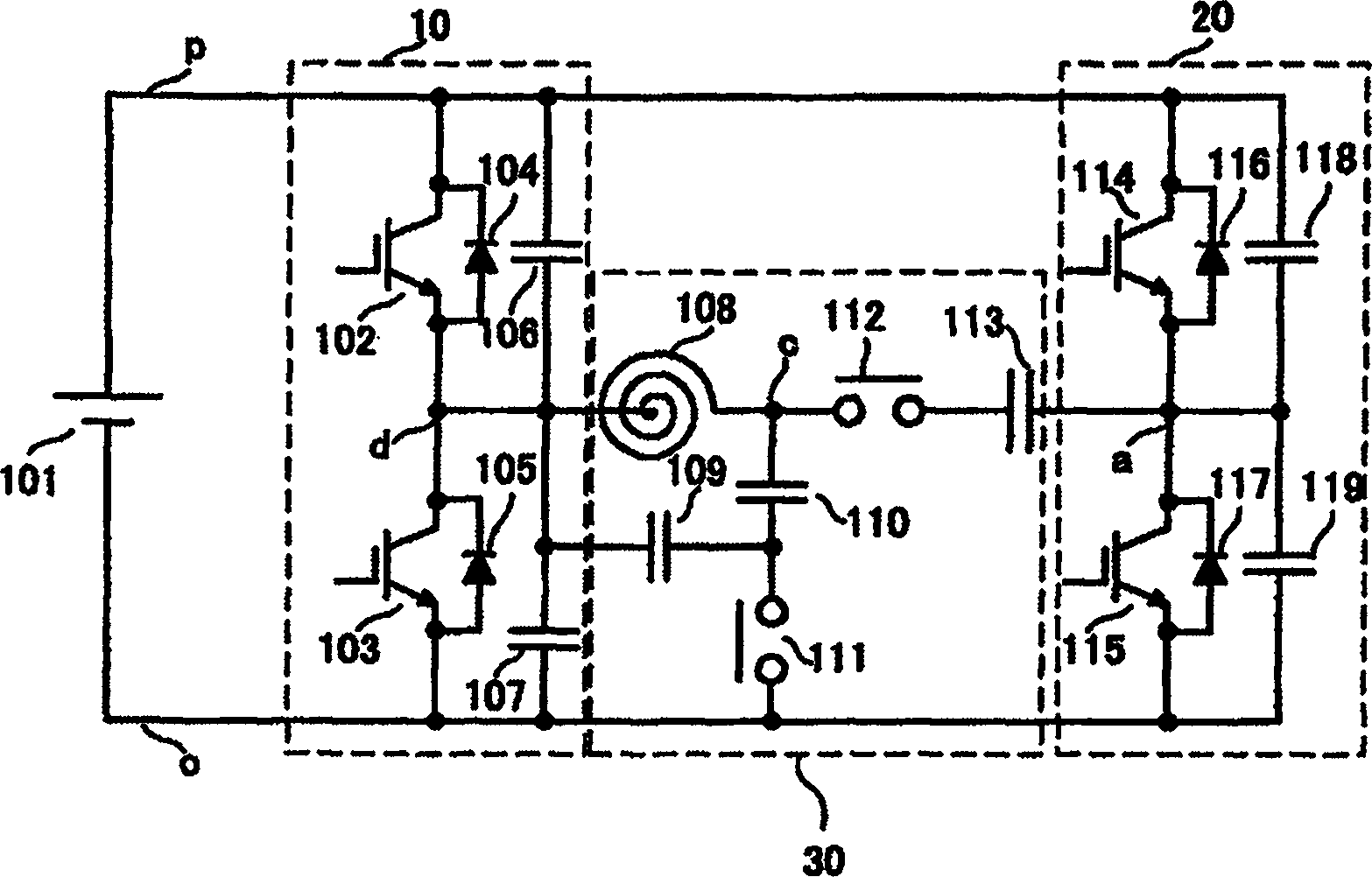

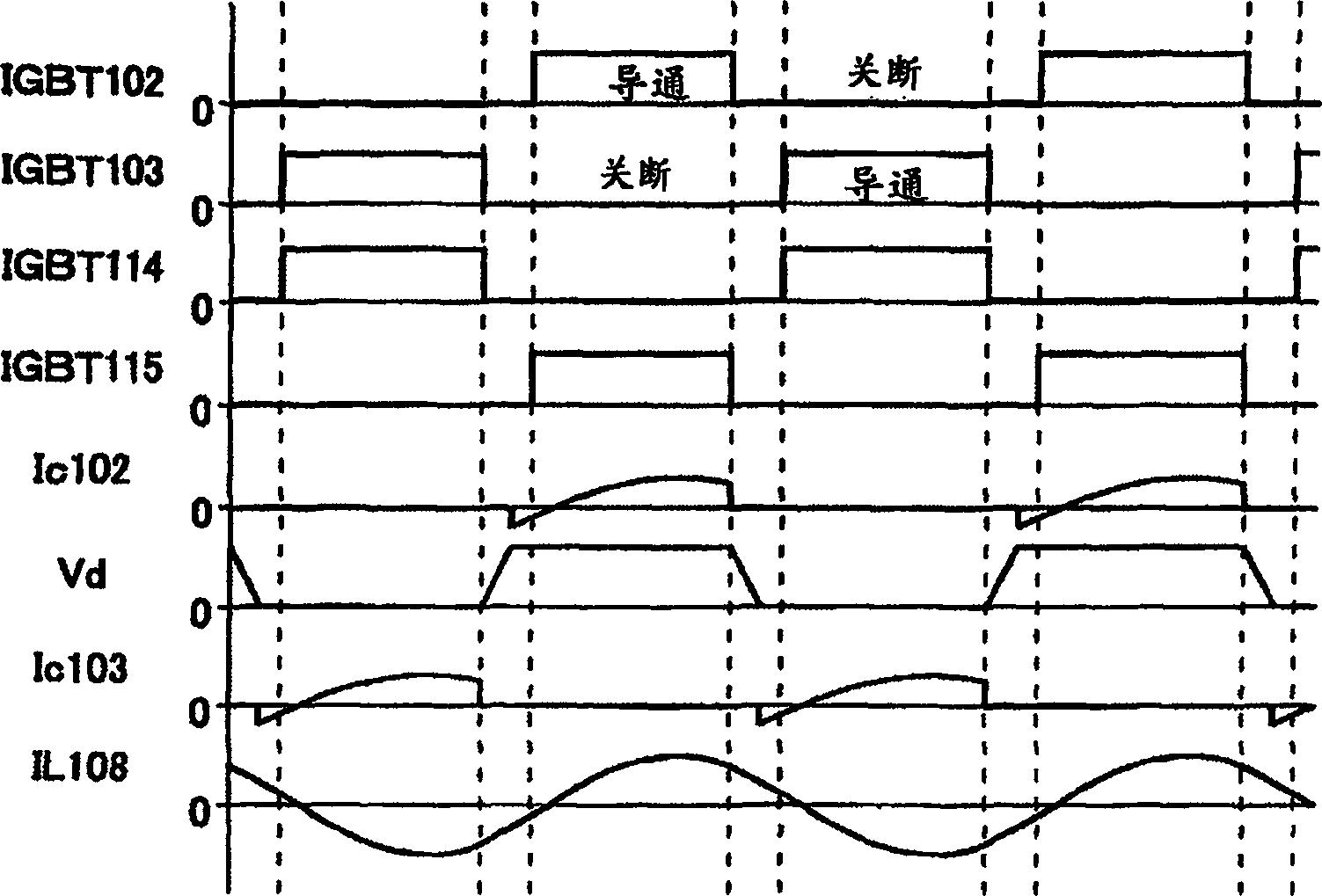

[0022] figure 1 It is a circuit configuration diagram of the induction heating device of this embodiment. exist figure 1 In the power supply circuit 101, between the point p on the positive electrode side and the point o on the negative electrode side, the upper and lower branches 10 connecting the power semiconductor switching elements, that is, IGBT102 and IGBT103 in series, and the upper and lower branches 10 connecting IGBT114 and IGBT115 in series are connected. Upper and lower branches 20. Diodes 104, 105 and diodes 116, 117 are connected in antiparallel to IGBT102, IGBT103, IGBT114, and IGBT115, respectively, and snubber capacitors 106, 107 and snubber capacitors 118, 119 are connected in parallel to each IGBT, respectively. Snubber capacitors 106 , 107 and snubber capacitors 118 , 119 are charged or discharged by the off-circuit current when IGBT102 , IGBT103 , IGBT114 , and IGBT115 are turned off. Since the capacitance of snubber capacitors 106, 107 and snubber cap...

Embodiment 2

[0051] Figure 5 It is a circuit configuration diagram of the induction heating device of this embodiment. exist Figure 5 in, for with figure 1 The same symbols are attached to the same constituent elements. Figure 5 In the point that the power supply circuits 101, 501 are provided in the upper and lower branches 10 and 20 respectively figure 1 different.

[0052] Between the point p on the positive electrode side and the point o on the negative electrode side of the power supply circuit 101 is connected a power semiconductor switching element, that is, an upper and lower branch 10 in which IGBT102 and IGBT103 are connected in series. On the other hand, another power supply circuit 501 is similarly connected to the upper and lower arms 20 in which IGBT114 and IGBT115 are connected in series. Diodes 104, 105 and diodes 116, 117 are connected in antiparallel to IGBT102, IGBT103, IGBT114, and IGBT115, respectively, and snubber capacitors 106, 107 and snubber capacitors 118...

Embodiment 3

[0055] Image 6 It is a circuit configuration diagram of the electromagnetic induction heating device of this embodiment. exist Image 6 In this example, a commercial AC power supply 603 is applied to a diode rectification circuit 604 and full-wave rectified, and then smoothed by an inductor 605 and a capacitor 606 to convert it into a DC voltage. For the power supply circuit 601, since the capacitance of the capacitor 606 is small, it is not completely smoothed, so the input current of the commercial AC power supply 603 is close to a sine wave, reducing high-order waves. In this example, if Figure 7 As shown in , since the DC voltage varies from 0 to the peak voltage of the commercial AC power supply 603, when heating an iron object to be heated, if the upper and lower branches 617 are driven, the unillustrated heating coil of the resonant load circuit 618 A resonant current that varies from 0 to the peak value flows in the middle. On the other hand, when heating an obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com