Mould for molded glass

A glass and mold technology, applied in the field of molds for molding high-precision or high-softening point glass lenses, can solve problems such as high prices, unfavorable market competition, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical means and functions used to achieve the purpose of the present invention will be described below with reference to the accompanying drawings, and the embodiments listed in the following figures are only for auxiliary illustration, and the technical means of the present invention are not limited to the listed accompanying drawings.

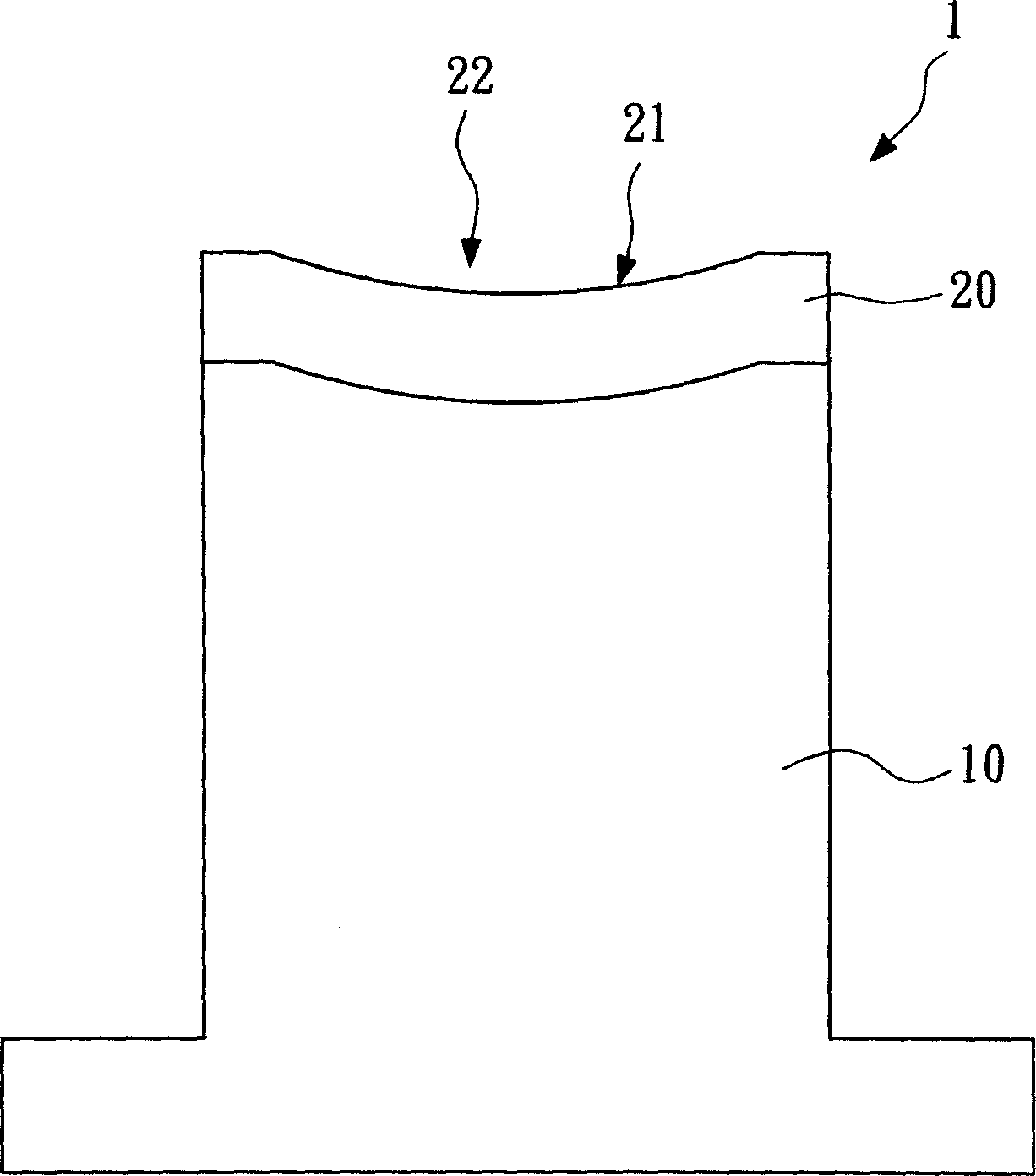

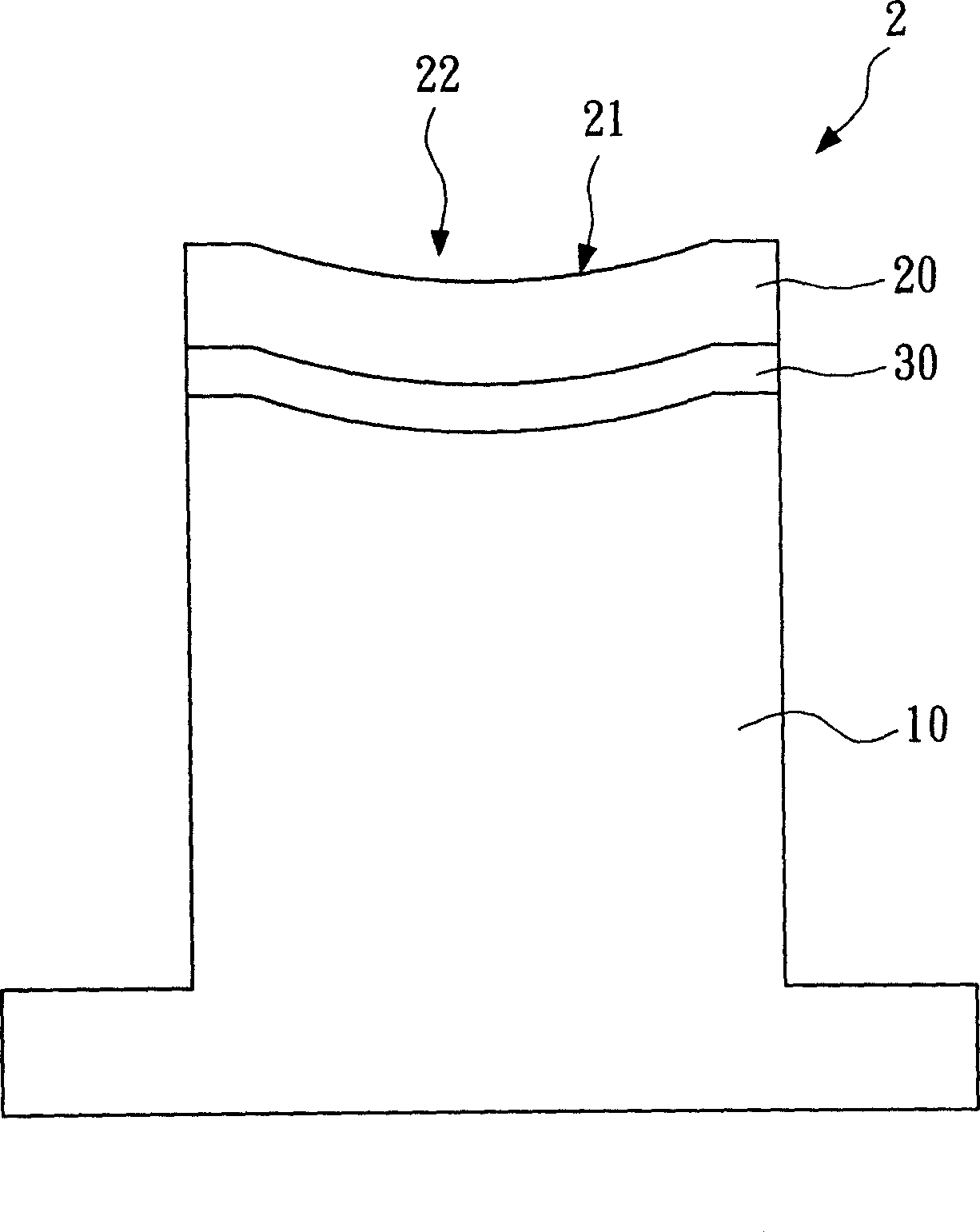

[0019] figure 1 is a schematic cross-sectional view of a mold for molding glass according to the present invention, which shows the first embodiment. Wherein, the mold 1 sequentially includes a substrate 10 and a protective film 20 stacked thereon.

[0020] When the mold 1 is made, at first the surface of the substrate 10 is ground and polished, wherein the material of the substrate 10 is a superhard alloy based on tungsten carbide (WC); then, a protection is formed on the substrate 10. Film 20, the material of the protective film 20 can be, for example, a protective film of molybdenum (Mo) and hafnium (Hf) metal alloy sputter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com