Mixing and preparing control method for mixed solution for fracturing, acidizing and sand control of oil field

A technology for oil field fracturing and control methods, which is applied in the fields of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of difficult operation, many control points, oil layer damage, etc., so as to avoid confusion. , Improve work efficiency and ensure the effect of uniform change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

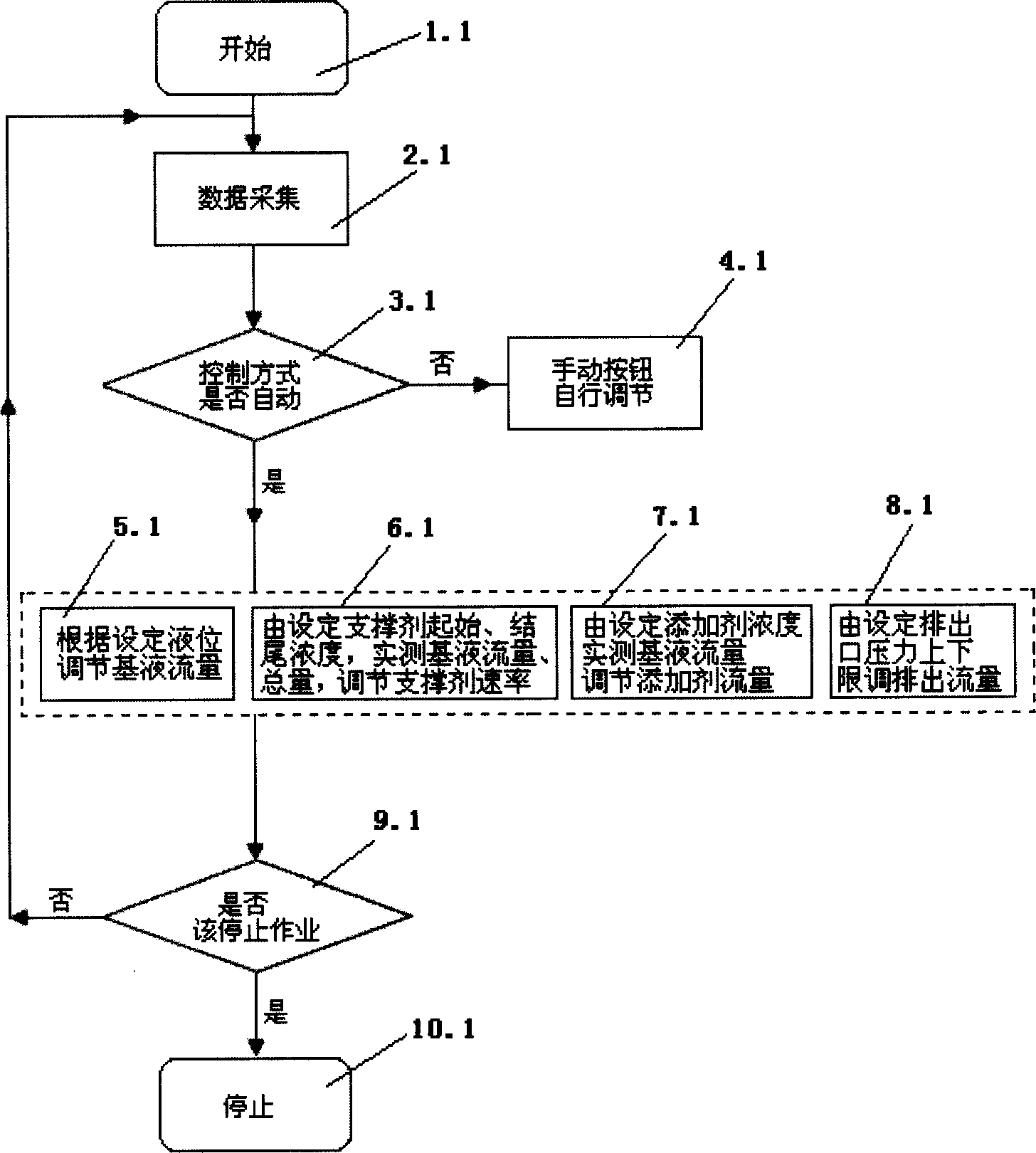

[0025] refer to Figure 1 to Figure 4 ,exist figure 1 In the program flow chart shown: 1.1. Start, 2.1. Data collection, 3.1. Whether the control mode is automatic, if not, then 4.1 The manual button adjusts itself, if so, then 5.1 Adjust the base liquid flow according to the set liquid level, 6.1. Adjust the proppant rate by setting the starting and ending concentration of the proppant, measuring the base fluid flow and total amount, 7.1 adjusting the additive flow by setting the additive concentration and measuring the base fluid flow, and 8.1 adjusting by setting the upper and lower limits of the outlet pressure Mixed liquid discharge flow, 9.1. Whether to stop the operation, if not, return, if so, then 10.1 stop.

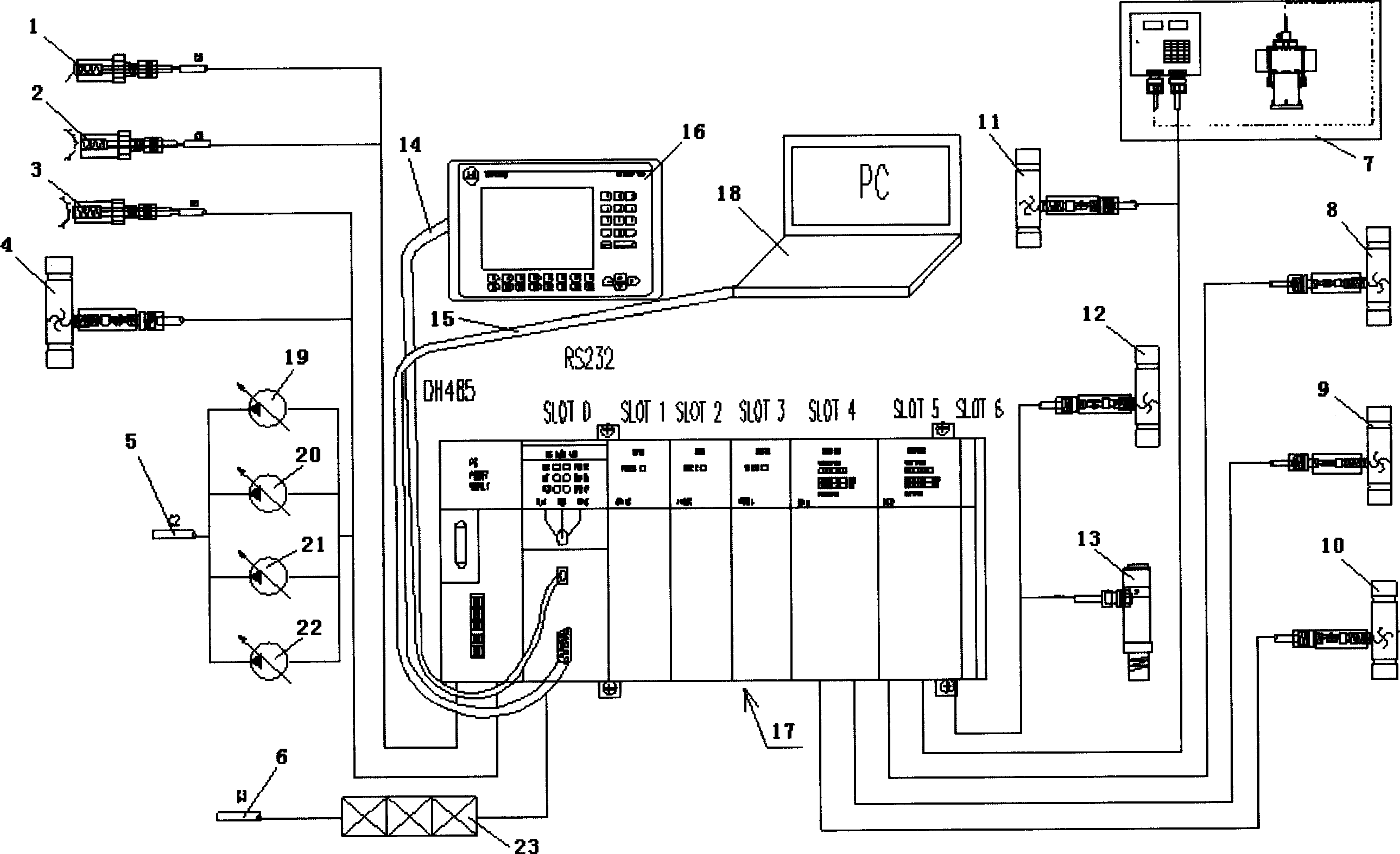

[0026] The control system implementing the control method of the present invention may include (see figure 2 ): 1. The pressure sensor at the outlet of the mixed liquid, 2. The speed sensor of the auger A, 3. The speed sensor of the auger B, 4. The turbine fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com