High-power blue-light fiber laser

A fiber laser, high-power technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of large size of laser devices, limited application range, low conversion efficiency, etc., to achieve high beam quality, high power, The effect of high frequency doubling conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

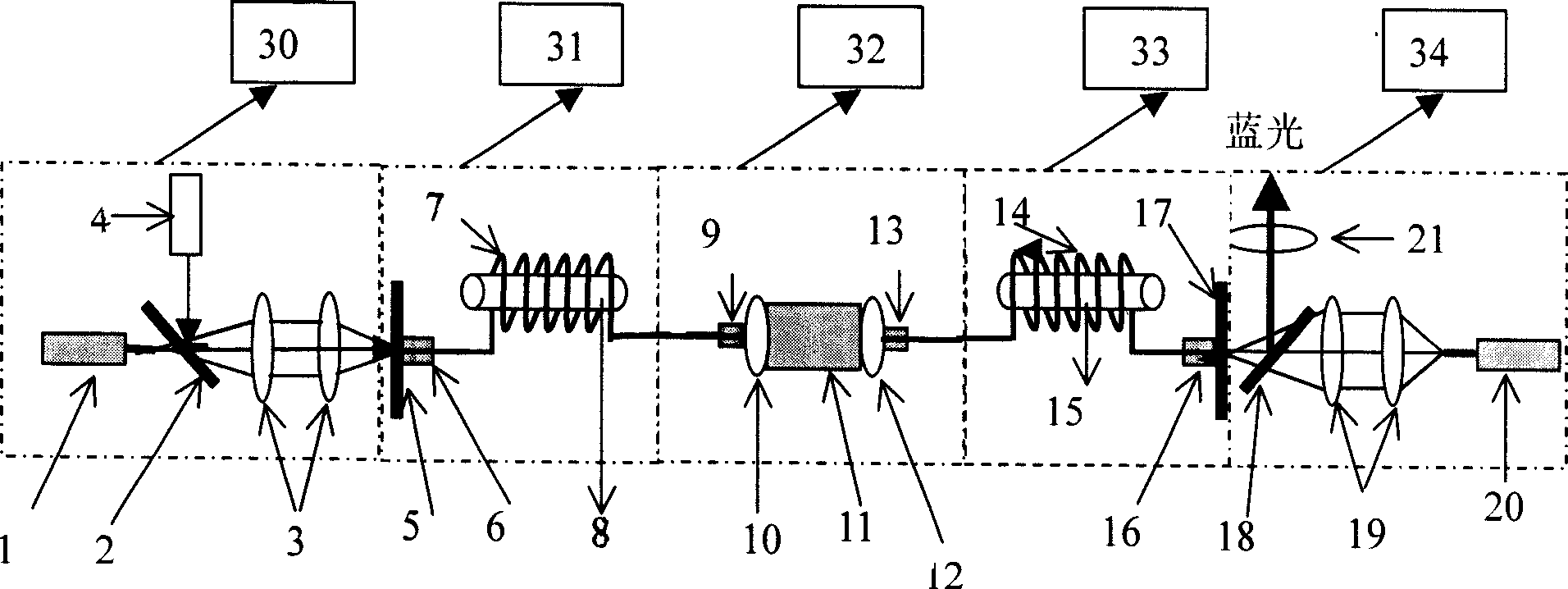

[0023] refer to figure 1 As shown, in the high-power blue fiber laser of the present invention, laser diode LD pumping source 1, dichromatic mirror 2, input coupling lens group 3 and dichromatic plate 5 are sequentially arranged along the optical path direction from left to right, and the four are in the On the same optical path, the dichromatic mirror 2 is placed with an inclination of 135°, the output of the signal source oscillator 4 is perpendicular to the optical path, and is arranged above the dichromatic mirror 2, the right end surface of the dichromatic film 5 is pasted and connected with the optical fiber pin 6, and the double The left end of the clad optical fiber 7 is inserted in the optical fiber ferrule 6 and the end face of the optical fiber is close to the two-color sheet 5, the rest of the first double-clad optical fiber 7 is wound on the optical fiber winding rod 8, and the right end of the first double-clad optical fiber 7 is inserted In the optical fiber fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com