Continuous water separation device

A separation device and container technology, applied in laboratory utensils, laboratory containers, chemical instruments and methods, etc., can solve the problems of low water separation efficiency, short residence time, difficult two-phase separation, etc. Increased productivity and improved separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

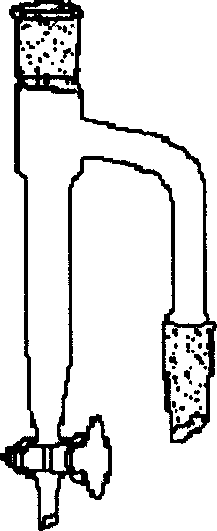

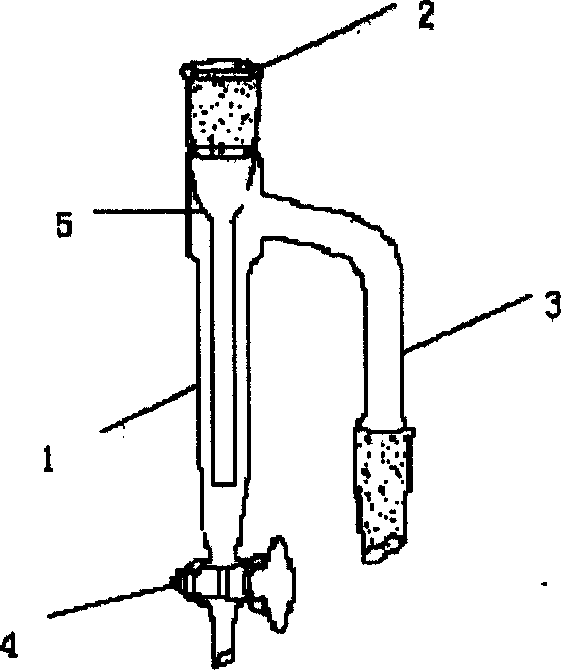

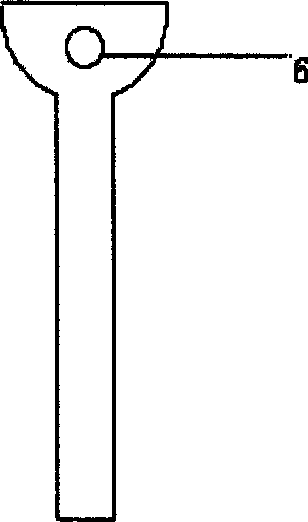

[0020] Such as figure 2 As shown, a continuous water separation device used in the laboratory, including a liquid inlet 2 with a standard grinding port, a container 1, an overflow pipe 3 with a standard grinding port and an outlet valve 4, the liquid inlet 2 and outlet valve 4 are respectively located at the top and bottom of the container 1, and the overflow pipe 3 is located at the upper part of the container 1. A liquid guide tube 5 is installed at the liquid inlet 2 , and the liquid guide tube 5 is inserted into the bottom of the container 1 , and its outlet is located above the outlet valve 4 . Such as image 3 As shown, a pressure balance hole 6 is opened on the top of the catheter 5 as a gas passage, and its position is higher than the liquid level of the container 1 . The water-organic mixed condensate from the condenser continuously enters the bottom of the container 1 from the liquid inlet 2 through the guide pipe 5, and is divided into two phases in the container...

Embodiment 2

[0022] Such as Figure 4 As shown, in the continuous water separation device realized in Embodiment 1 above, an appropriate number of perforated sieve plates 7 are installed in the container 1 , and the perforated sieve plates 7 are located between the overflow pipe 3 and the outlet valve 4 . There are many small holes distributed on the perforated sieve plate 7, such as Figure 5 As shown, as a redistributor, the separation effect of water and organic matter can be significantly improved. Especially when the emulsification phenomenon occurs between water and organic matter, it can overcome the defect that the existing water separation device is difficult to separate.

Embodiment 3

[0024] Such as Figure 6 As shown, in the continuous water separation device realized in the second embodiment above, a condensation jacket 9 is added outside it. The condensing jacket 9 plays a cooling role, which can further reduce the temperature of the mixed condensate in the water separation device, significantly reduce the miscibility of water and organic matter, and thus the separation efficiency can be greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com