Guide float valve tray

A float valve tray and float valve technology, which is applied in the field of fractionation towers, can solve the problems of not fully exerting the gas propelling effect, the liquid flow does not have a guiding effect, and reducing the gas outlet area, etc., so as to increase the mass transfer contact area, reduce the Small resistance, the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

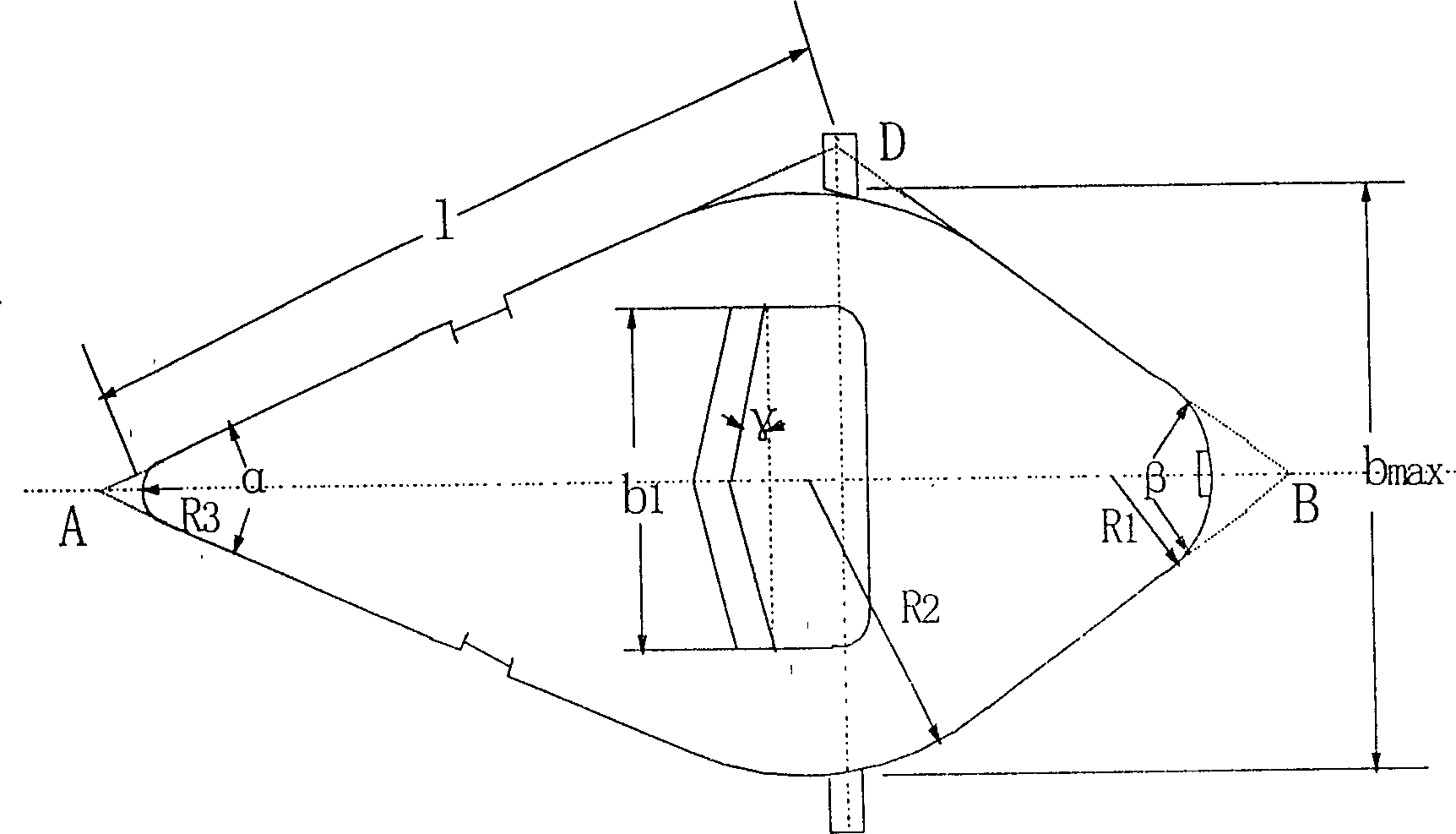

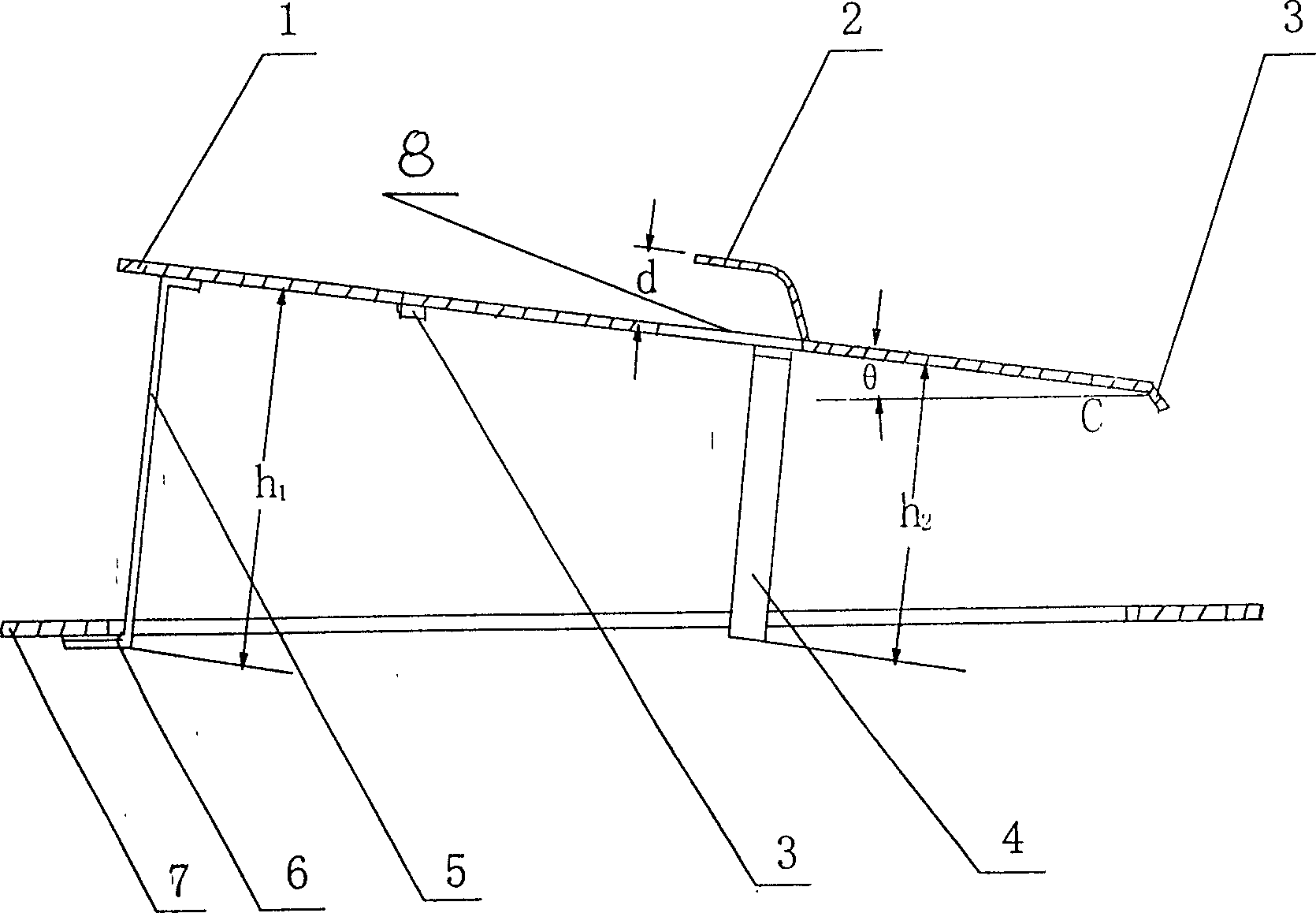

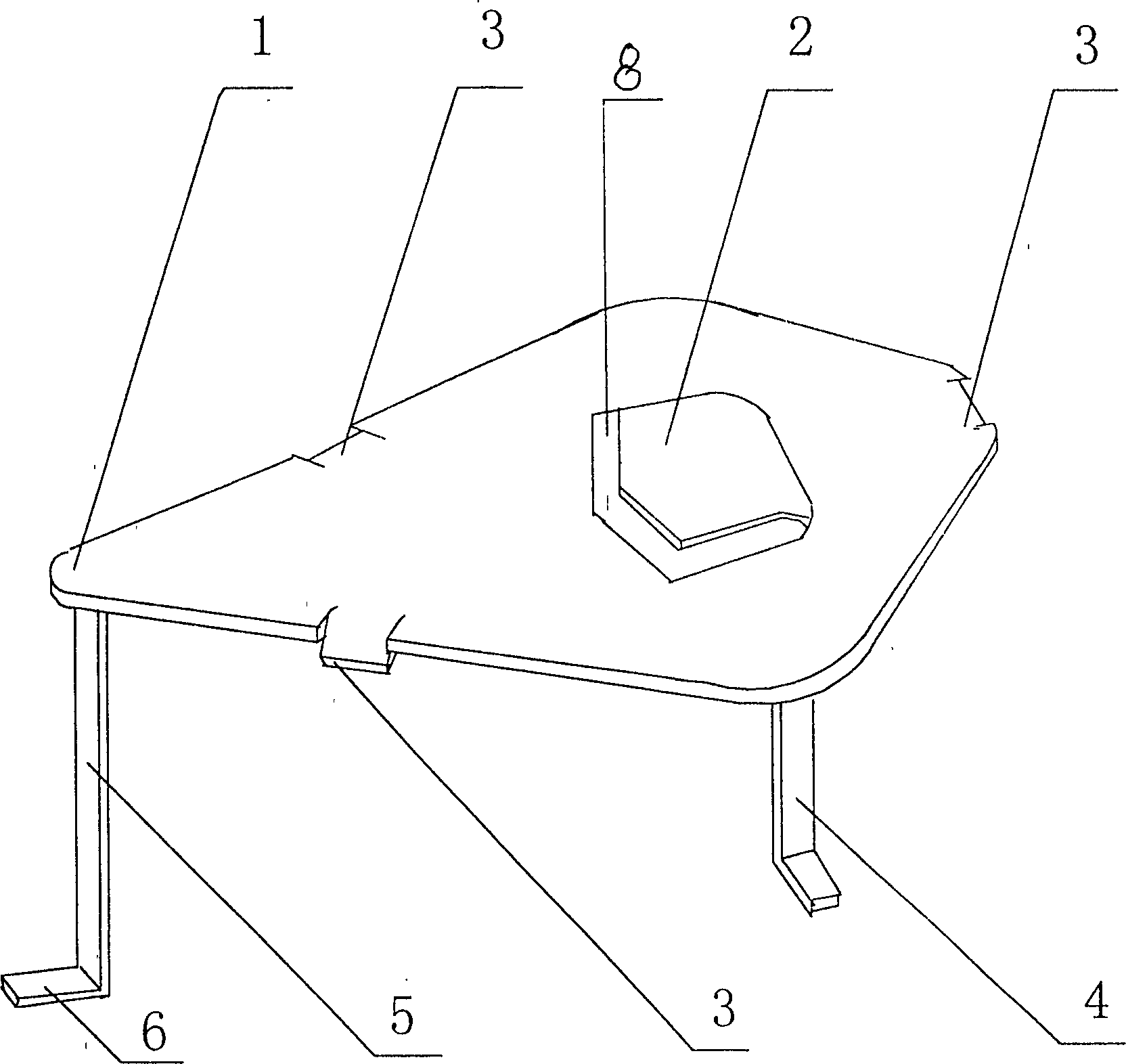

[0021] Propylene oxide-water rectification system adopts the symmetrical quadrilateral guide valve tray of the present invention to transform the original F1 type float valve tray. The valve adopts such as Figure 4 For the fork row method shown in b, the valve center distance S = 220mm, and the distance between the float valve rows t = 150mm. Guided symmetrical quadrilateral float valve such as figure 1 , 2 As shown in and 3, the long side AD of the symmetrical quadrilateral guide valve cover 1 has a length l=70mm, a front angle α=35°, a back angle β=60°, and the radii of the four corner arcs are respectively R 1 = 30mm, R 2 = 50mm, R 3 =10mm, there is a guide hole 8 on the valve cover 1, the guide hole 8 is pentagonal, and its shape is a combination of an isosceles triangle and a rectangle, and the angle between the two waists of the isosceles triangle and the base is γ=15 °, the width of the guide hole b 1 =0.6b, b is the maximum width of the valve cover. A guide pla...

Embodiment 2

[0023] Methane chloride chilling tower, the processing capacity is 20000t / a, the tower diameter is φ1800mm, the original tower is a sieve plate tower, the plate spacing is 500mm, the opening rate is 12%, and the number of trays is 12, due to the unsatisfactory heat transfer effect And adopt guide float valve tray of the present invention, its concrete structure parameter is: plate spacing 500mm, opening ratio 12%, tower diameter is constant, and tray number is constant, and the AD length l=60mm of float valve bonnet 1, Front angle α=30°, rear angle β=57°, R 1 , R 2 , R 3 Respectively 25, 45, 8mm, γ=10°, b 1 =0.5b, the length of the front valve leg 5 is h 1 =38mm, length of rear valve leg h 2 = 25mm, the operation results show that the outlet temperature of the vapor phase at the top of the tower drops from 125°C to 106°C, and the operating flexibility changes from 1.8:1 to 2.4:1 and it can run normally. In addition, the pressure drop of the whole tower is changed from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com