Thermal gasification recovery and treatment method for cladded metal containing metal film paster and device therefor

A technology for recycling and processing metal films, applied in waste treatment, solid waste removal, etc., can solve problems such as single function, environmental damage, occupation of space environment, etc., to achieve outstanding functions and functions, more raw materials, and good prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

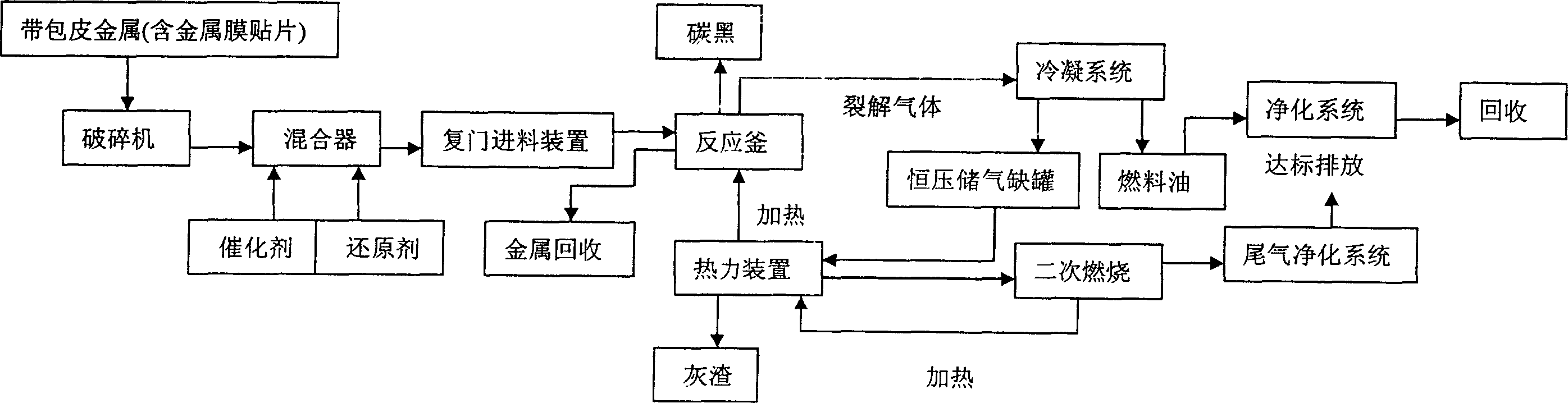

[0029] Such as figure 1 Shown, the effect of each step of recovery processing method of the present invention is:

[0030] 1. Crusher

[0031] Considering that the volume of the metal-containing film patch with sheath varies, and the size of the feeding device and the feed port of the reactor are fixed, it is necessary to set up a crusher to achieve the purpose of reducing the volume of feeding, and the degree of crushing depends on It depends on the specific model of the device. For example, the cutting size of general wires is 200mm to 500mm, and the broken area of the patch containing metal film is not more than 150mm×150mm.

[0032] 2. Mixer

[0033] After determining the type and quantity of the catalyst and reducing agent according to the type of material and the amount of feed, the catalyst and reducing agent are evenly mixed with the simply crushed raw materials to ensure the normal, rapid and complete reaction. The catalyst is selected from silicon dioxide and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com