Preparation system of palm-based artificial graphite

A technology of artificial graphite and preparation system, which is applied in the field of palm-based artificial graphite preparation system, can solve the problems of low degree of graphitization, low product recovery efficiency, high production cost, etc., and achieve reduced environmental pollution, fast yield and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

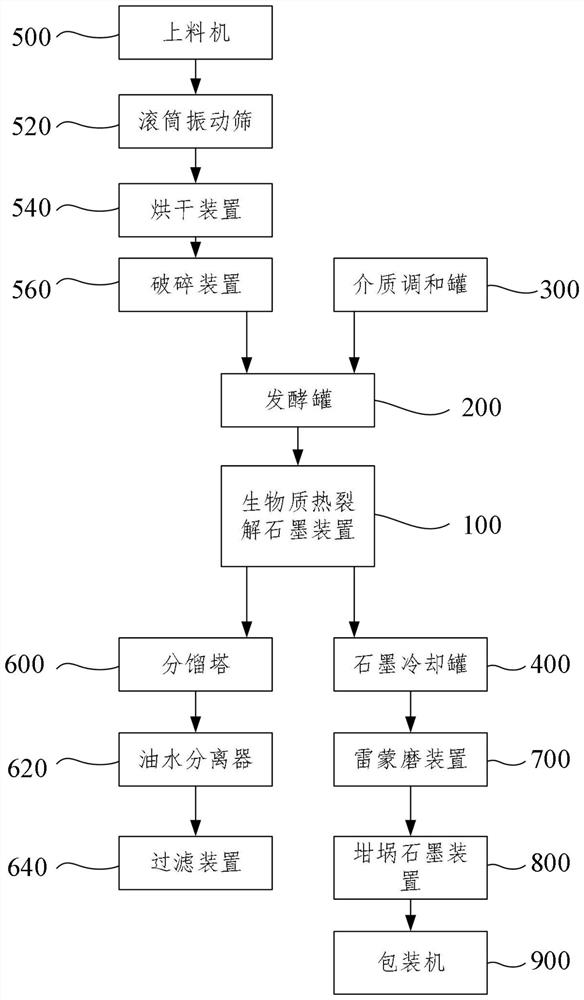

[0054] like Figure 1 to Figure 8 As shown, a preparation system of palm-based artificial graphite in this embodiment includes a feeder 500, a drum vibrating screen 520, a drying device 540, a crushing device 560, a medium mixing tank 300, a fermentation tank 200, and biomass cracking Graphite device 100, graphite cooling tank 400, Raymond mill device 700, crucible graphite device 800 and packing machine 900; The mouth is connected with the feed port of the drying device 540, the discharge port of the drying device 540 is connected with the discharge port of the crushing device 560, the discharge port of the crushing device 560 and the medium mixing tank 300 are all connected with the fermentation tank 200, and the fermentation The discharge port of the tank 200 is connected with the feed port of the biomass cracking graphite device 100, the graphite material outlet of the biomass cracking graphite device 100 is connected with the graphite cooling tank 400, and the graphite co...

Embodiment 2

[0057] like figure 1 and figure 2 As shown, a preparation system of palm-based artificial graphite in this embodiment includes all the technical features in Embodiment 1, in addition, it also includes a fractionation tower 600, an oil-water separator 620 and a filter device 640; biomass Fractionation tower 600 is installed above the pyrolysis reactor of pyrolysis graphite device 100, and the liquid outlet of fractionation tower 600 is communicated with the inlet of oil-water separator 620, and the oil outlet of oil-water separator 620 is communicated with filtering device 640; Gas purification device, the hot gas generated by the furnace body of the biomass pyrolysis graphite device 100 is introduced into the fermentation tank 200 and the medium blending tank 300 through the induced draft fan for heating, and the air outlets of the fermentation tank 200 and the medium blending tank 300 are treated by the flue gas purification device Rear discharge; also includes a burner and...

Embodiment 3

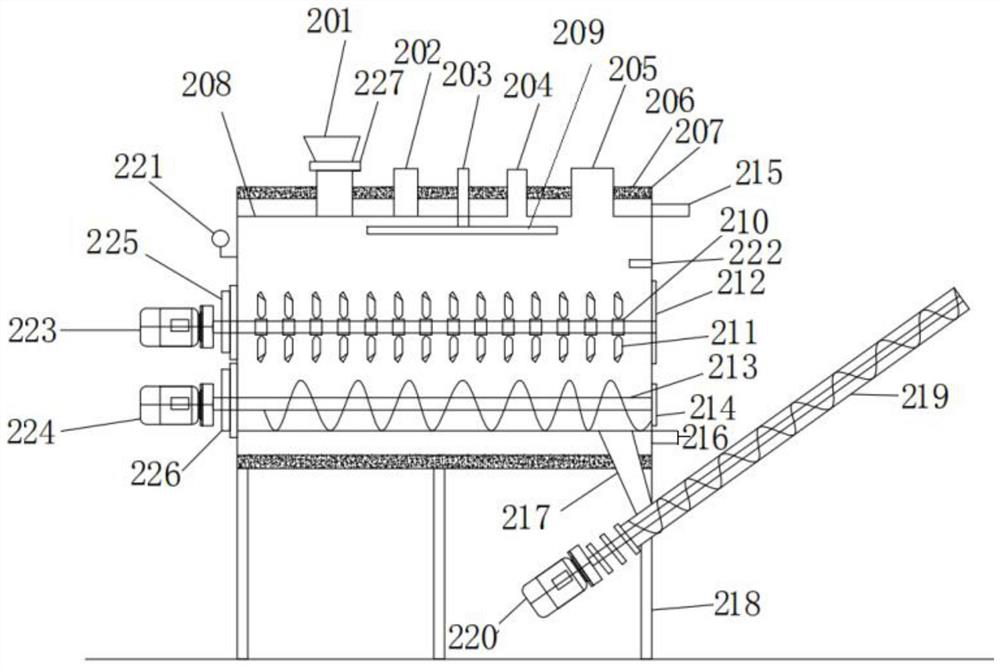

[0063] like image 3 As shown, the preparation system of a kind of palm-based artificial graphite in the present embodiment includes all the technical features in Embodiment 1. In addition, the fermentor 200 includes a fermentation outer tank body 207, a fermentation inner tank body 208, a fermentation Stirring device, fermentation conveying device and fermentation feeding device, the fermentation outer tank body 207 and the fermentation inner tank body 208 are hollow structures, the fermentation outer tank body 207 is set on the outer peripheral side of the fermentation inner tank body 208, and the fermentation inner tank body 208 An annular hollow and sealed heating chamber is formed between the fermentation outer tank body 207, and a fermentation air inlet 216 and a fermentation air outlet 215 are arranged on the common end surface of the fermentation inner tank body 208 and the fermentation outer tank body 207, and the fermentation inner tank body The inner cavity of 208 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com