Cation acrylamide copolymer water-in-water emulsion and its preparation method

A technology of acrylamide copolymer and water-in-water emulsion, which is applied in the field of cationic acrylamide copolymer water-in-water emulsion and its preparation. High active matter content and other issues, to achieve the effect of low cost, lower viscosity and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. A cationic acrylamide copolymer water-in-water emulsion. It includes 25% by weight of active cationic polymer, 15% by weight of polymer stabilizer and 15% by weight of inorganic salt. The active cationic polymer contains 72.8-90 mol% of at least one water-soluble monomer (A), 10-26 mol% of at least one cationic monomer (B) and 0.2-1.0 mol% of at least one hydrophobic monomer (C). The polymer is obtained by radical polymerization under the condition of pH 3-8.

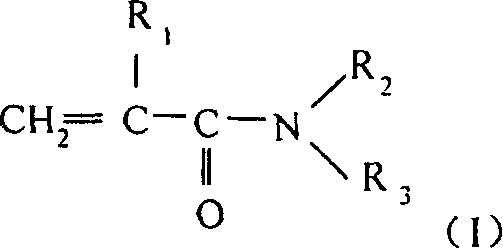

[0035] Monomer (A) is a molecule corresponding to the following general formula (I):

[0036]

[0037] where R 1 means H or CH 3 , R 2 and R 3 Each independently represents H, C 1 -C 6 Alkyl or cycloalkyl; Monomer (B) is a molecule corresponding to the following general formula:

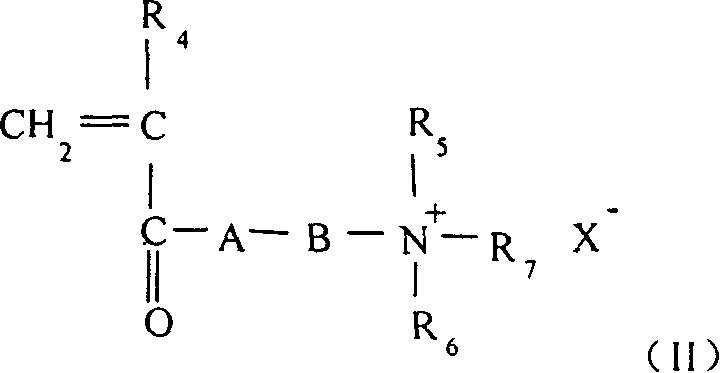

[0038] Monomer B having the following general formula (II) 1

[0039]

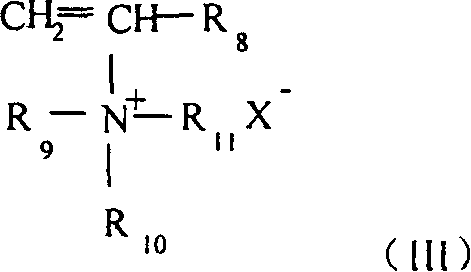

[0040] Where A represents O or NH, B represents CH 2 CH 2 、CH 2 CH 2 CH 2 or CH 2 CHOHCH 2 , R 4 means H or CH 3 , R 5 and R ...

Embodiment 2

[0048] Example 2. A cationic acrylamide copolymer water-in-water emulsion. It includes 15 wt% active cationic polymer, 1.0 wt% polymer stabilizer and 22 wt% inorganic salt. The active cationic polymer contains 72.8-90 mol% of at least one water-soluble monomer (A), 10-26 mol% of at least one cationic monomer (B) and 0.2-1.0 mol% of at least one hydrophobic monomer (C). The polymer is obtained by radical polymerization under the condition of pH 3-8.

[0049] Monomer (A) is a molecule corresponding to the following general formula (I):

[0050]

[0051] where R 1 means H or CH 3 , R 2 and R 3 Each independently represents H, C 1 -C 6 Alkyl or cycloalkyl; Monomer (B) is a molecule corresponding to the following general formula:

[0052] Monomer B having the following general formula (II) 1

[0053]

[0054] Where A represents O or NH, B represents CH 2 CH 2 、CH 2 CH 2 CH 2 or CH 2 CHOHCH 2 , R 4 means H or CH 3 , R 5 and R 6 Each independently represe...

Embodiment 3

[0062] Example 3. A cationic acrylamide copolymer water-in-water emulsion. It includes 5 wt% cationic polymer, 30 wt% polymer stabilizer and 32 wt% inorganic salt. The active cationic polymer contains 72.8-90 mol% of at least one water-soluble monomer (A), 10-26 mol% of at least one cationic monomer (B) and 0.2-1.0 mol% of at least one hydrophobic monomer (C). The polymer is obtained by radical polymerization under the condition of pH 3-8.

[0063] Monomer (A) is a molecule corresponding to the following general formula (I):

[0064]

[0065] where R 1 means H or CH 3 , R 2 and R 3 Each independently represents H, C 1 -C 6 Alkyl or cycloalkyl; Monomer (B) is a molecule corresponding to the following general formula:

[0066] Monomer B having the following general formula (II) 1

[0067]

[0068] Where A represents O or NH, B represents CH 2 CH 2 、CH 2 CH 2 CH 2 or CH 2 CHOHCH 2 , R 4 means H or CH 3 , R 5 and R 6 Each independently represents CH 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com