Production process of high density carbonized bamboo material

A processing method and high-density technology, applied in wood processing equipment, impregnated wood, manufacturing tools, etc., can solve the problems of high manufacturing cost, easily damaged bamboo, high energy consumption, etc., and achieve good product quality, convenient operation, and no pollution environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

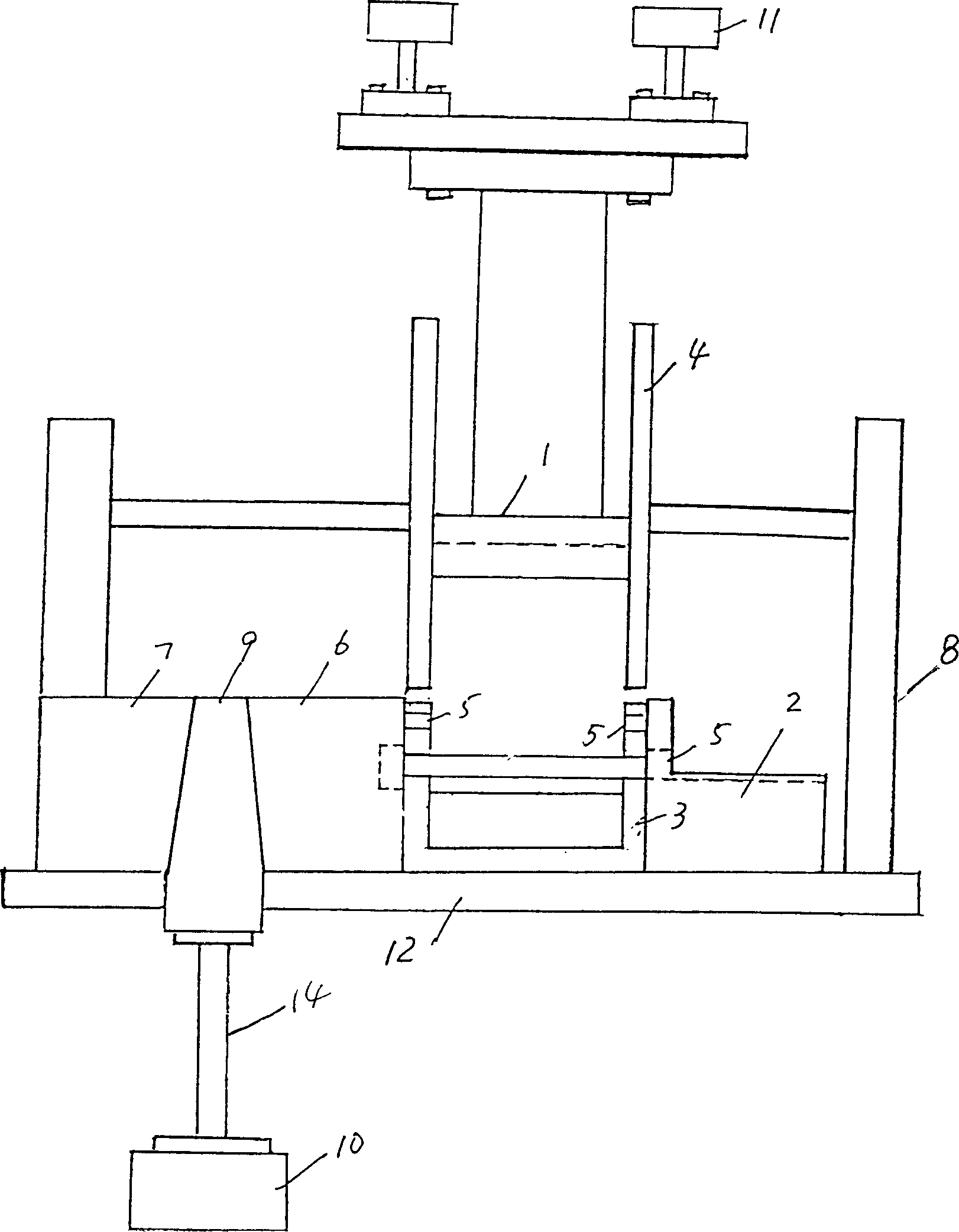

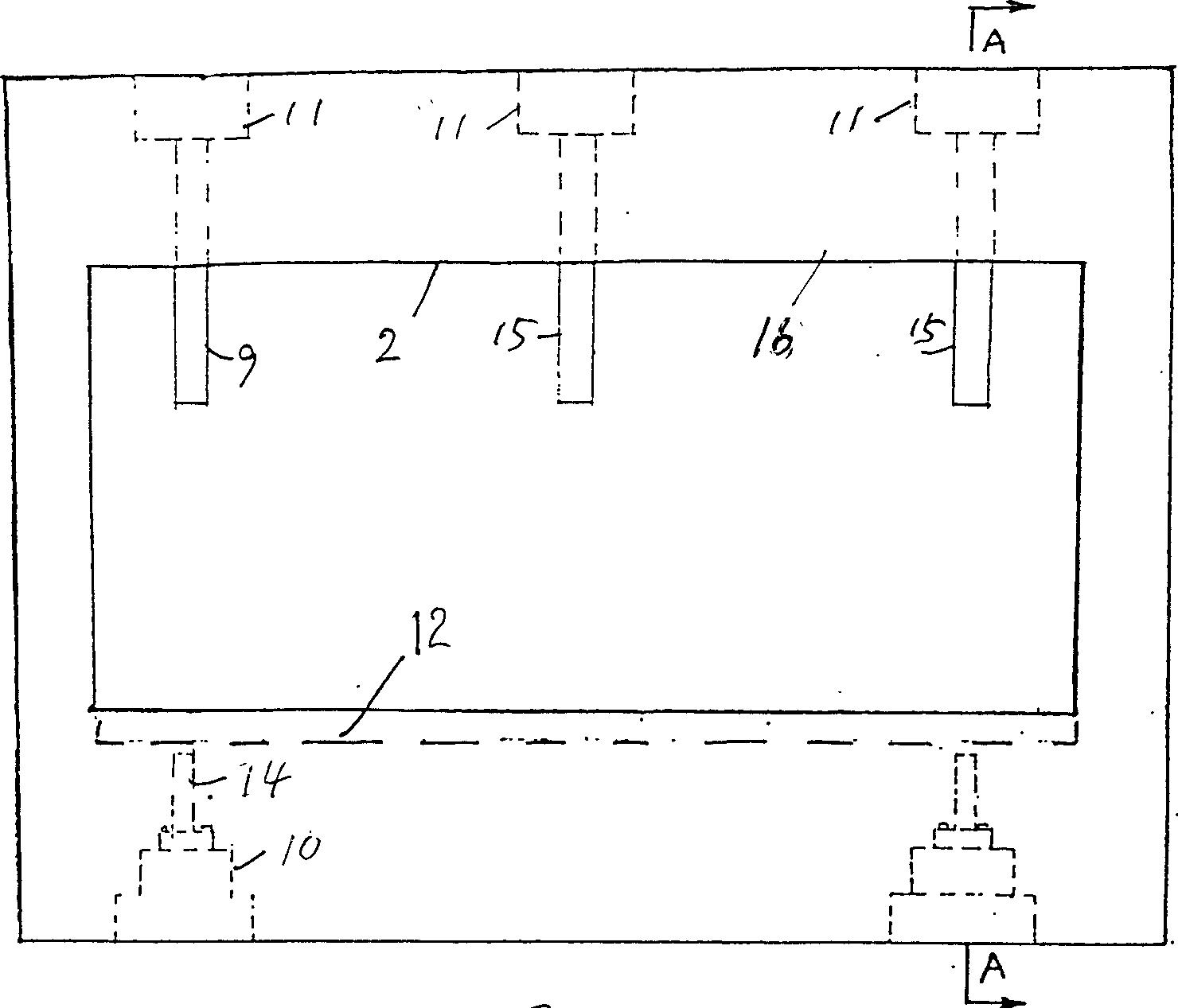

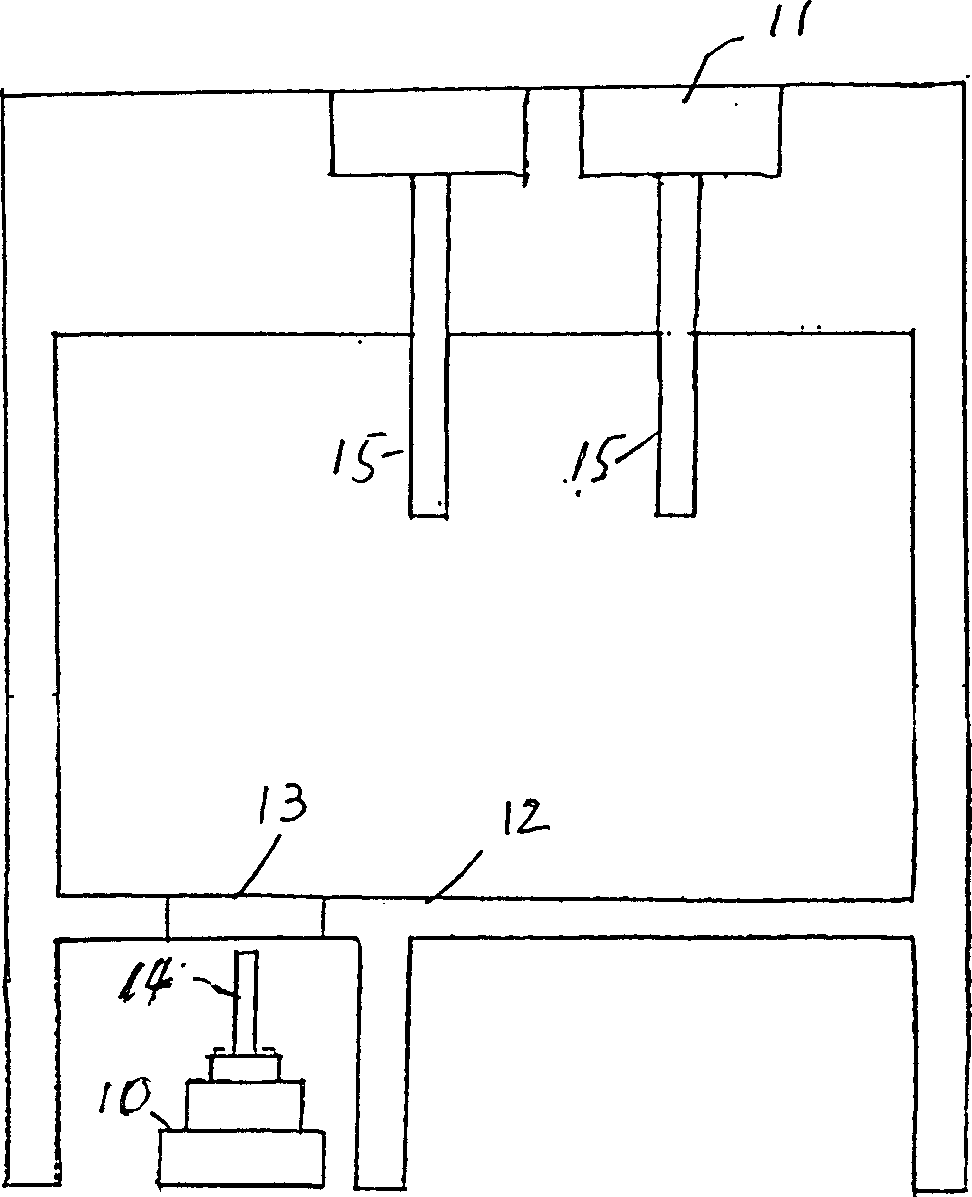

Image

Examples

Embodiment Construction

[0034] Process flow of the present invention is as follows:

[0035] 1. Process the bamboo into 0.4-2m long, 1.4-2.4cm wide, and 1.2-2mm thick bamboo slices, remove the green layer of 0.8-1mm, and remove the dead yellow to make the product free of wax and sugar, and reach the final product The adhesion is tight without peeling off. The bamboo slices are classified and combined, and enter the next process respectively.

[0036] 2. Use a silk mill to grind the bamboo slices into vertically and horizontally connected bamboo shreds, so that the bamboo slices have gaps, so that the glue can penetrate evenly and bond tightly.

[0037] 3. Disinfect, desugar, degrease, and soften, use 2-5% hydrogen peroxide, 2-3% baking soda, 3-8% bleaching powder, 2-3% sulfite fish oil, and the rest as water to make softener. Put it into a softener, boil it in water for 1-2 hours at a temperature of 80-100°C, make the fibrous tissue expand and eliminate internal stress, remove fat, oil, and sterili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com