Second-order non-linear optical crystal material and its synthesis process and use

A second-order nonlinear and optical crystal technology, applied in the field of optical materials and inorganic chemistry, to achieve high nonlinear optical coefficient and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

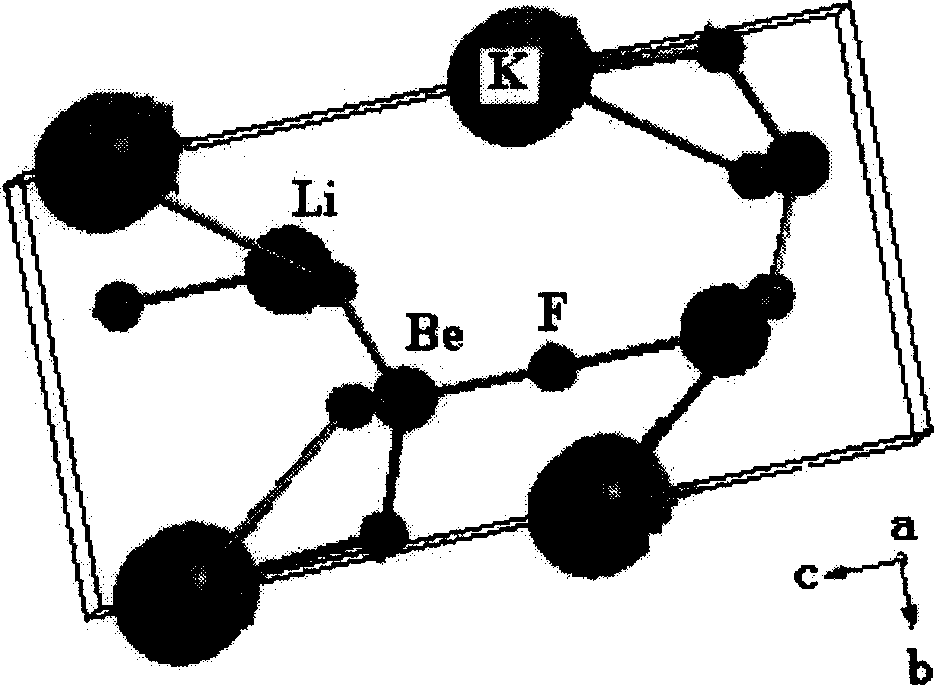

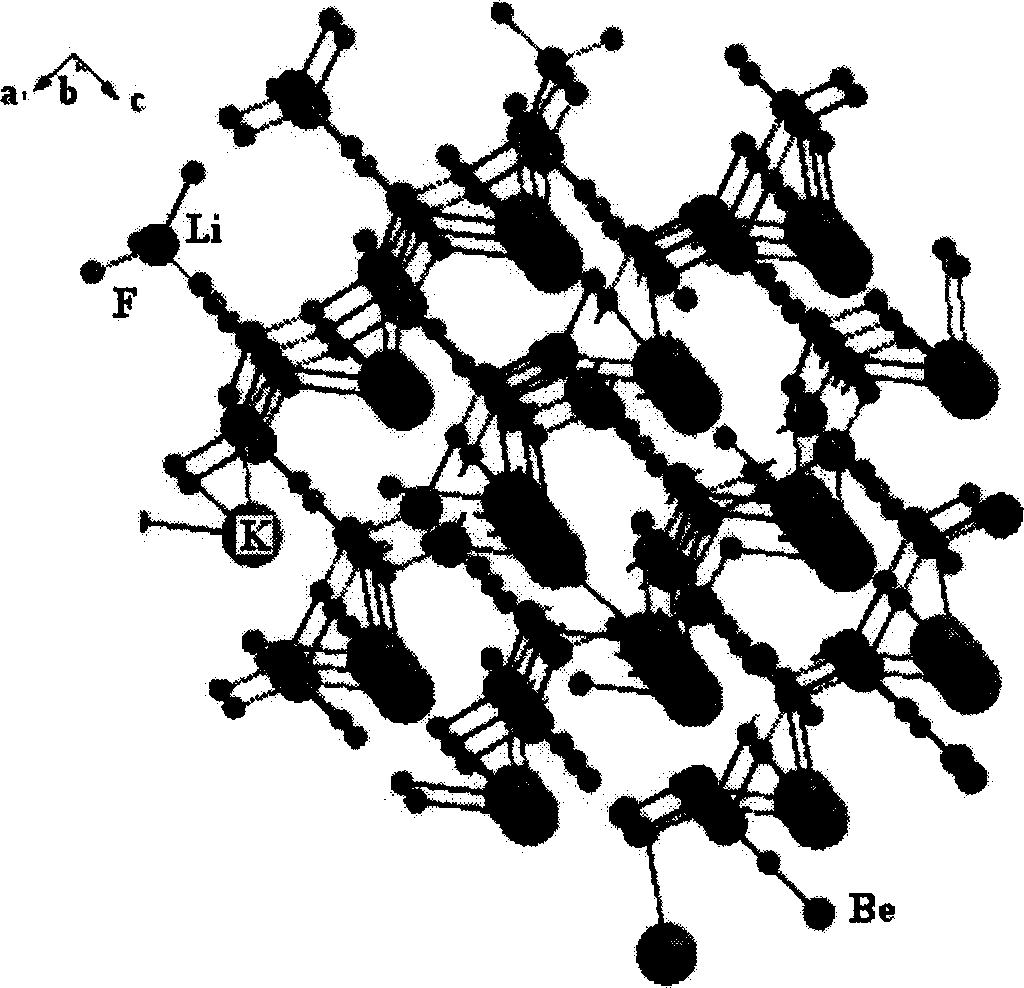

Method used

Image

Examples

Embodiment 1

[0023] Example 1: KLiBeF 4 Single crystal preparation

[0024] Put 0.96 g lithium hydroxide (40 mmol), 2.24 g potassium hydroxide (40 mmol), 1.88 g beryllium fluoride (40 mmol) and 2.20 g ammonium hydrofluoride (40 mmol) into polytetrafluoroethylene In the ethylene reactor (volume about 20 ml), add 10 ml of distilled water, under stirring, add hydrofluoric acid, adjust the pH value to 6. Sealed, heated to 140 degrees Celsius, and kept at a constant temperature for 25 hours. Naturally cooled to room temperature, filtered to obtain a large number of colorless and transparent crystals. The product is washed repeatedly with distilled water and dried in vacuum to obtain colorless and transparent KLiBeF directly. 4 single crystal.

Embodiment 2

[0025] Example 2: KLiBeF 4 Single crystal preparation

[0026] Put 0.96 g of lithium hydroxide (40 mmol), 2.24 g of potassium hydroxide (40 mmol), 1.88 g of beryllium fluoride (40 mmol) and 4.40 g of ammonium hydrofluoride (80 mmol) into polytetrafluoroethylene In the ethylene reactor (capacity about 20 ml), add 14 ml of distilled water, under stirring, add hydrofluoric acid, adjust the pH value to 7. Sealed, heated to 150 degrees Celsius, and kept at a constant temperature for 30 hours. Naturally cooled to room temperature, filtered to obtain a large number of colorless and transparent crystals. The product is washed repeatedly with distilled water and dried in vacuum to obtain colorless and transparent KLiBeF directly. 4 single crystal.

Embodiment 3

[0027] Example 3: KLiBeF 4 Single crystal preparation

[0028] Put 0.96 g of lithium hydroxide (40 mmol), 2.24 g of potassium hydroxide (40 mmol), 1.88 g of beryllium fluoride (40 mmol) and 6.60 g of ammonium hydrofluoride (120 mmol) into polytetrafluoroethylene In the ethylene reactor (about 20 ml in volume), add 16 ml of distilled water, and under stirring, add hydrofluoric acid to adjust the pH value to 5. Sealed, heated to 160 degrees Celsius, and kept at a constant temperature for 20 hours. Naturally cooled to room temperature, filtered to obtain a large number of colorless and transparent crystals. The product is washed repeatedly with distilled water and dried in vacuum to obtain colorless and transparent KLiBeF directly. 4 single crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com