Concrete drilling hole machine with friction sheet

A friction plate and drilling machine technology, applied in the direction of friction clutches, rotary drilling machines, drilling equipment and methods, etc., can solve the problems of inability to drill holes, high cost, drilling teeth, etc., and achieve high drilling efficiency and light weight , to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

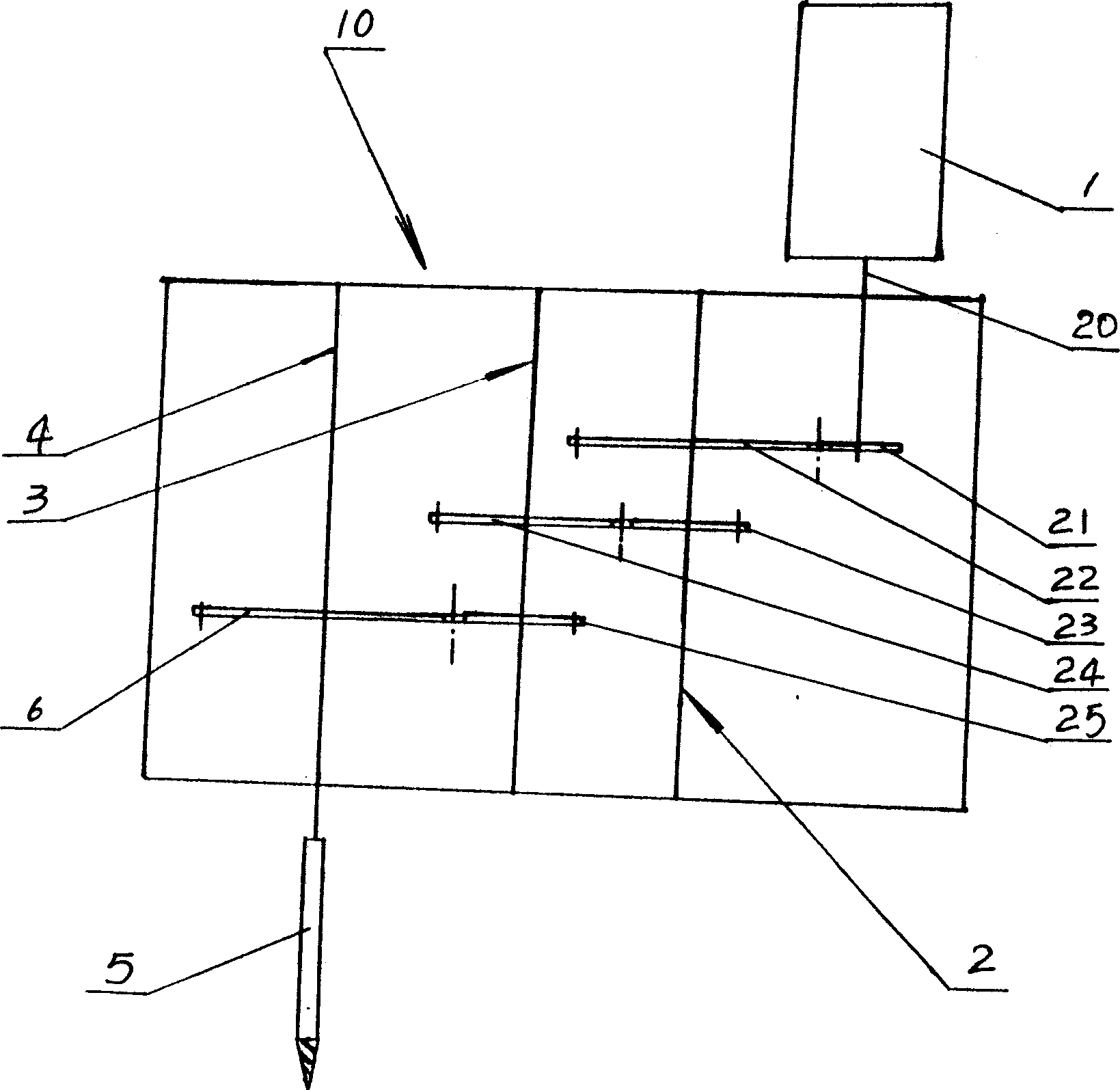

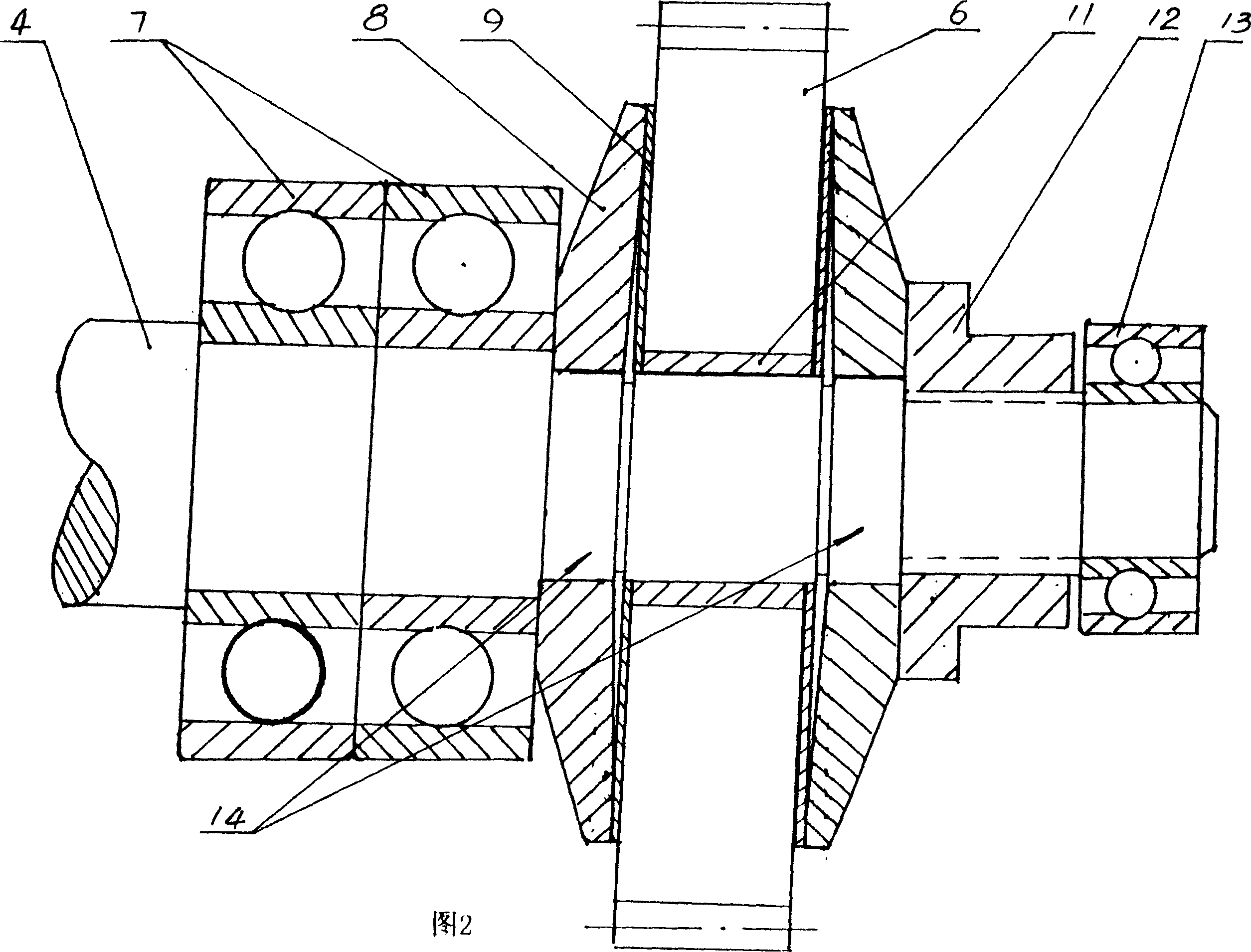

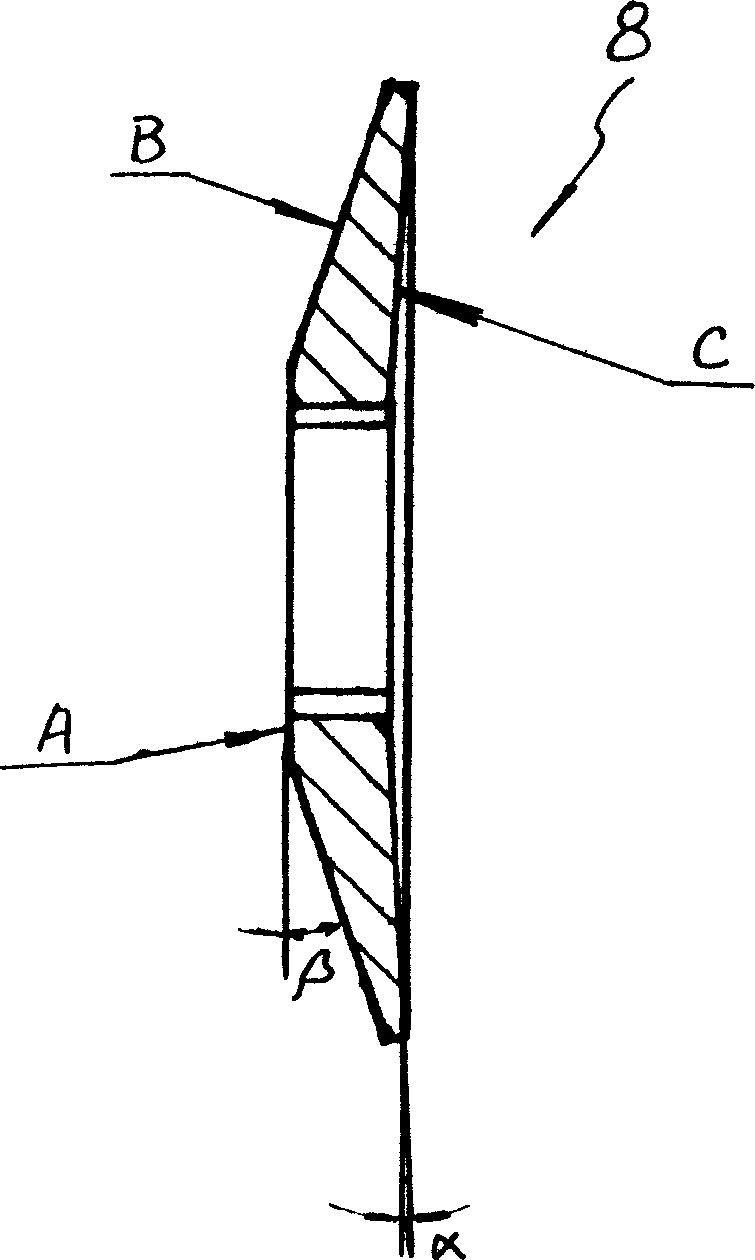

[0019] figure 1 It is a schematic diagram of the gearbox transmission mechanism of the present invention; Fig. 2 is figure 1 Partial enlarged cross-sectional view of the elastic friction structure on both sides of the main gear assembled on the output shaft in the middle gearbox; image 3 It is a half-sectional view of the elastic pressure puller in Fig. 2; Figure 4 yes image 3 right view of Figure 5 It is the front view of the friction plate in Fig. 2; Figure 6 yes Figure 5 left view of .

[0020] As shown in the figure, the present invention provides a concrete drilling machine with a friction plate. The structure of the concrete drilling machine includes: a motor 1; a gearbox 10 connected to the motor 1; Concrete drill bit 5. The friction discs 9 on both sides of the main gear 6 on the output shaft 4 in the gearbox 10 are installed.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap