Electric connector, unit for covering its connected part between two terminals, storage cell and bus bar equipped with them

An electrical connector and battery technology, which is applied to the parts of the connecting device, the two-part connecting device, and the parts of the battery pack, etc., can solve the problems that the connector is smaller than the battery, is not easy to see, and damages the engaging part, etc. Achieve the effect of improving assembly efficiency, simple assembly and disassembly operations, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0147] Below, according to the attached Figure 1 While describing various embodiments of the present invention, the present invention will be described in more detail.

[0148] First, refer to figure 1 and figure 2 A basic embodiment of an electrical storage device in which the connector of the present invention can be suitably used will be described.

[0149] This power storage device is, for example, a large capacitor constituted by a plurality of electric double layer capacitor cells (battery batteries), and is used as a supercapacitor of a power storage power supply device of an electric vehicle.

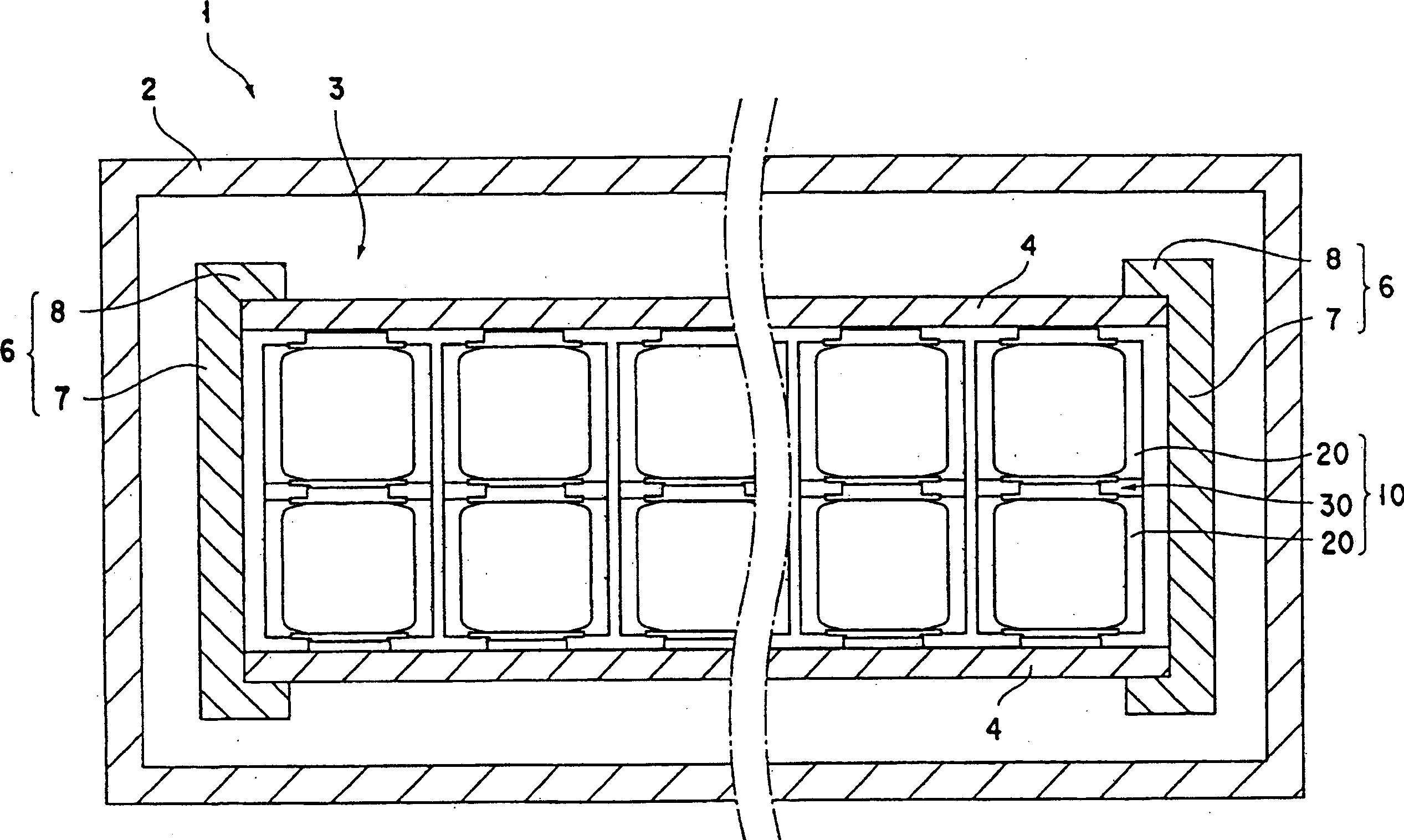

[0150] Such as figure 1 As shown, the power storage device 1 has a frame body 2 and a power storage module 3. The frame body 2 has a storage space inside; the power storage module 3 is housed in the frame body 2 and has a large power storage capacity.

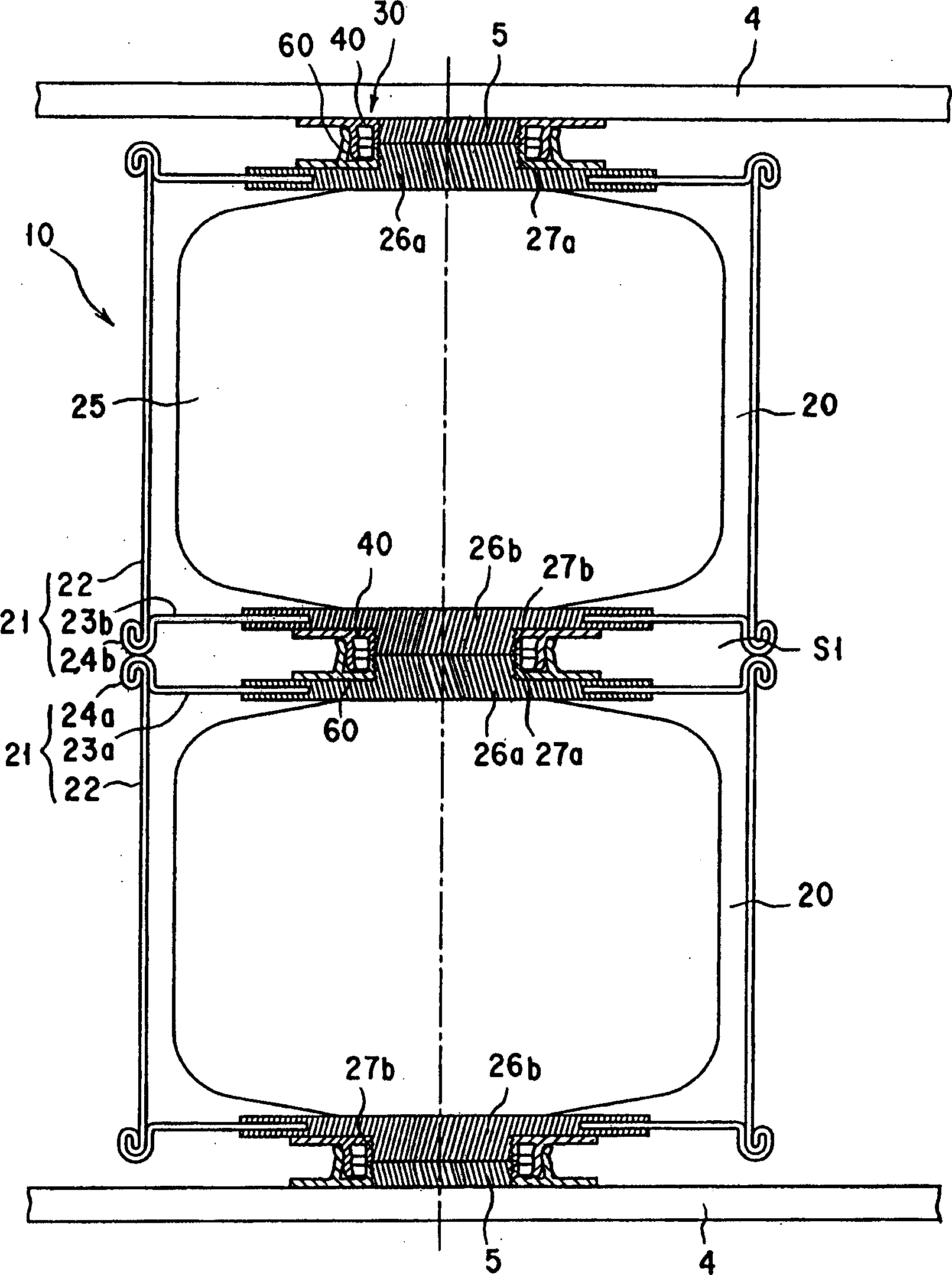

[0151] The storage battery module 3 has a capacitor unit (storage battery) 20, a bus bar 4, a binding plate (enclosed wit...

Deformed example 1

[0192] Refer to the following Figure 9 Modification 1 of the connector of the present invention will be described.

[0193] The basic structure of Modification 1 is the same as that of the connector 30 described in the first embodiment, but this Modification 1 is characterized by the female thread portion provided on the inner ring portion. In the following description, although the male connector part is used as an example, it is also applicable to the female connector part.

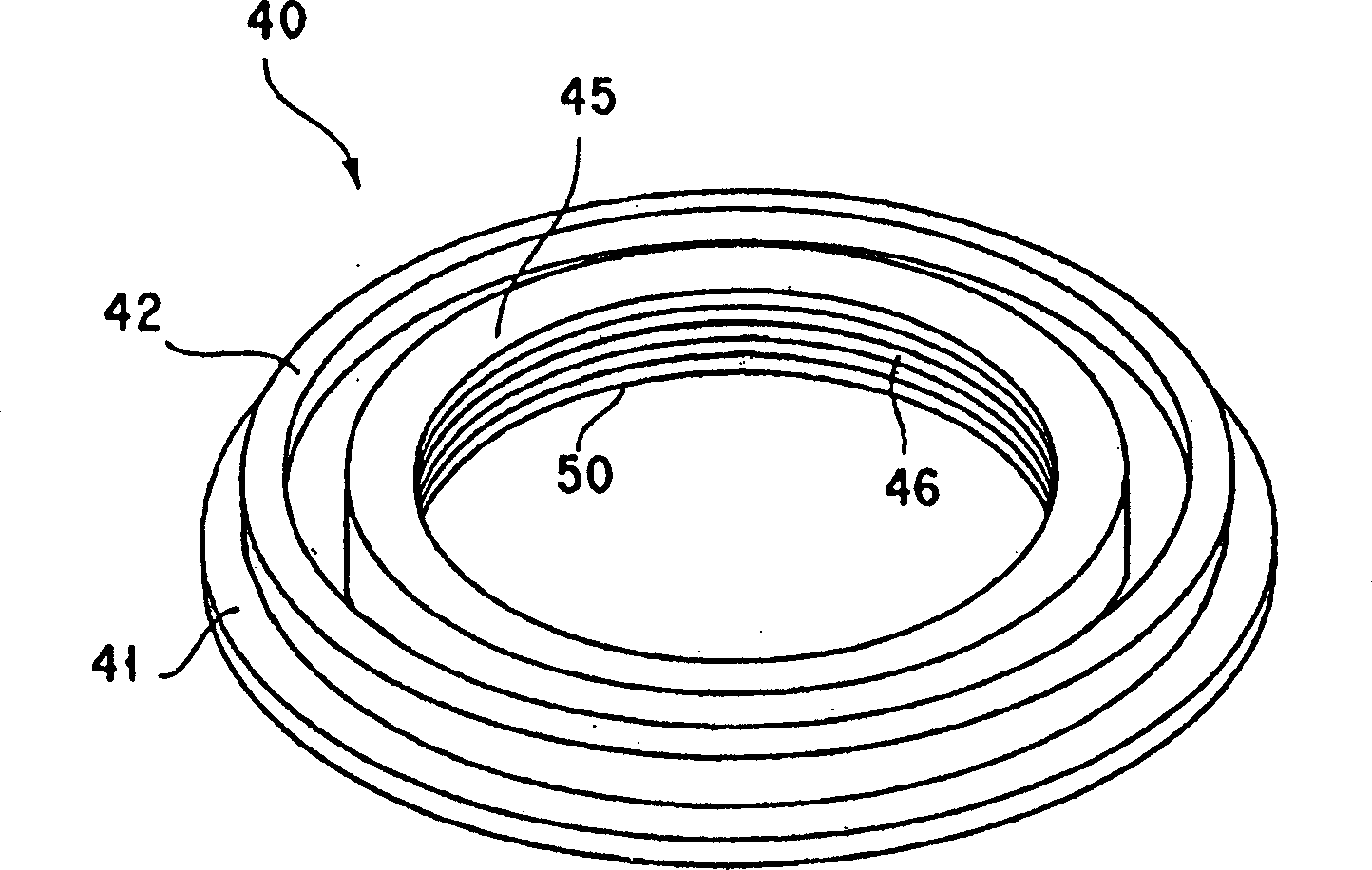

[0194] Figure 9 The male connector part 40a of the illustrated connector 30 has a base portion 41 , an outer ring portion 42 and an inner ring portion 45 .

[0195] A female thread portion 46 is provided on the inner peripheral surface of the inner ring portion 45 . Further, a groove 47 is recessed in the inner peripheral surface of the inner ring portion 45 in the axial direction (cylindrical axis direction) of the inner ring portion 45 . The grooves 47 are provided at predetermined intervals, fo...

Deformed example 2

[0200] Refer to the following Figure 10 Modification 2 of the connector of the present invention will be described.

[0201] The basic structure of Modification 2 is the same as Modification 1, but Modification 2 is characterized by having a handle portion. In addition, in the following description, although the male connector part is used as an example for description, it is also applicable to the female connector part.

[0202] Figure 10 The male connector part 40b of the illustrated connector 30 has a base portion 41, an outer ring portion 42, and an inner ring portion 45 having an internal thread portion 46 and a groove 47 formed by roll forming on the inner peripheral surface thereof.

[0203] exist Figure 10 In the upper end portion of the inner ring portion 45, a handle portion 48 protruding radially is provided. The handle portion 48 is formed in connection with the groove 47, and three are provided at intervals of 120°.

[0204] Here, a method of forming the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com