High-frequency-multiplication efficiency green laser producing method

A generation method and laser technology, which are applied to lasers, laser parts, phonon exciters, etc., can solve the problems of low KTP damage threshold, high-power frequency-doubling gray traces, and output two beams of green light, etc. The effect of short cavity length and improved beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

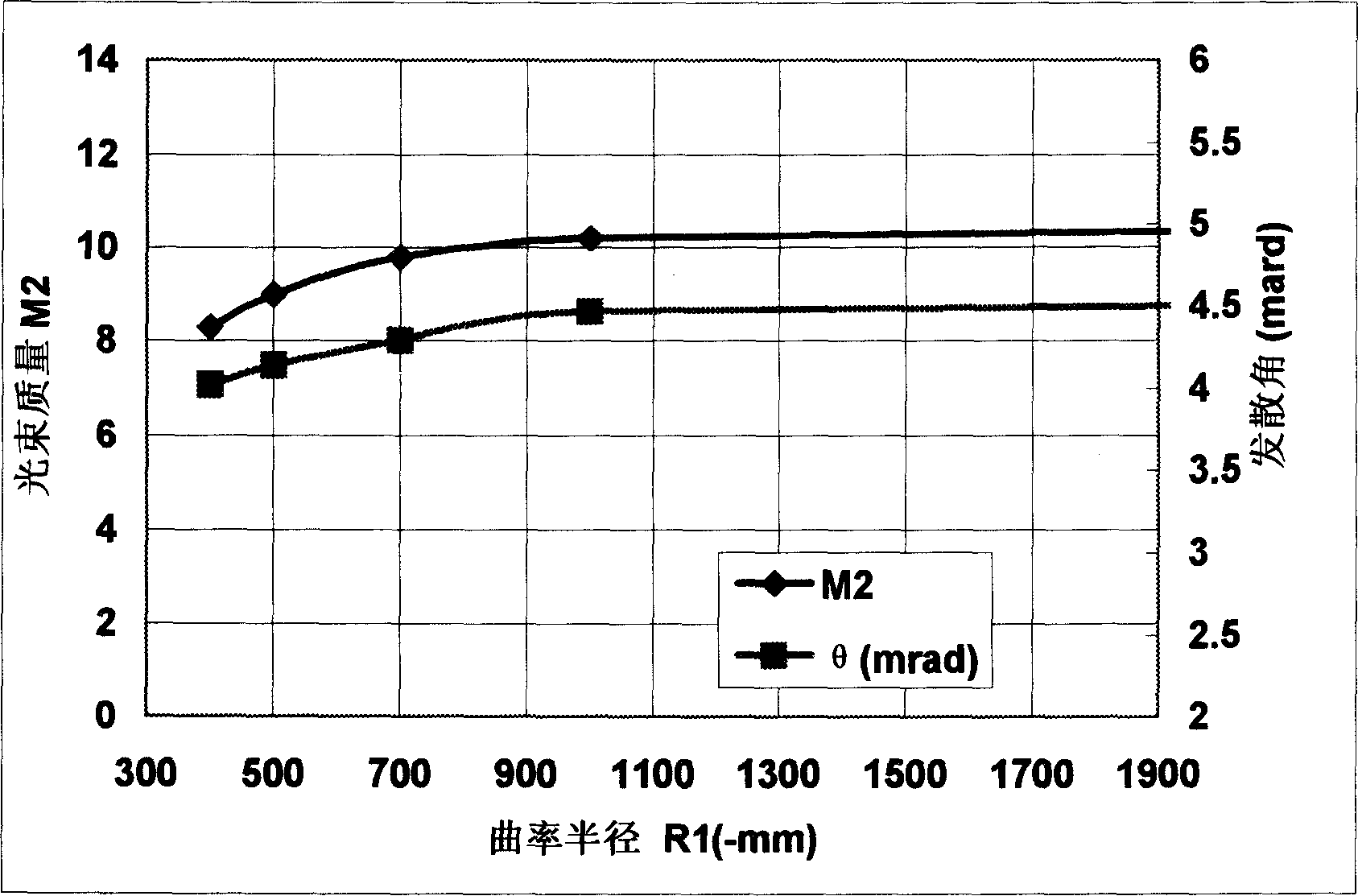

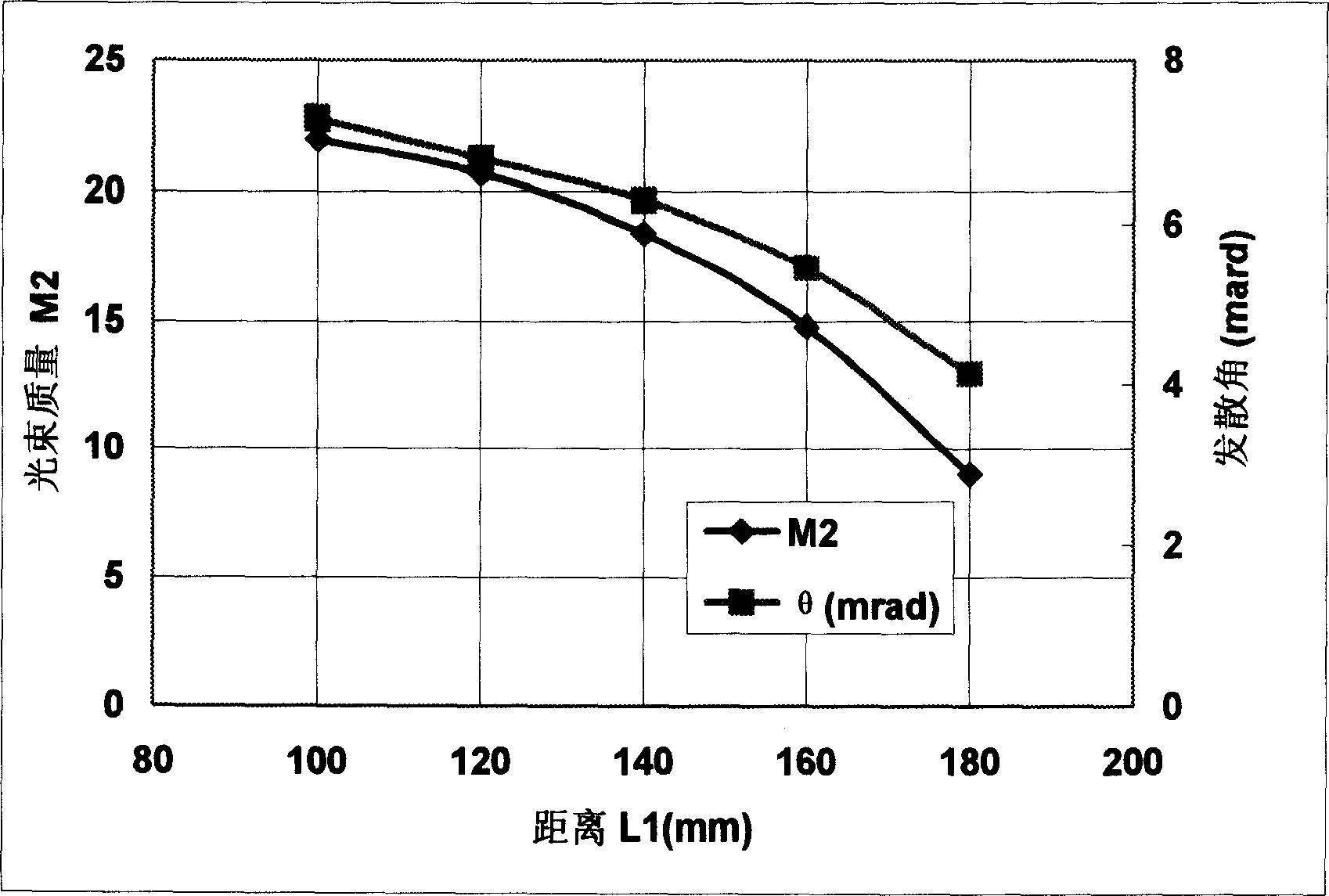

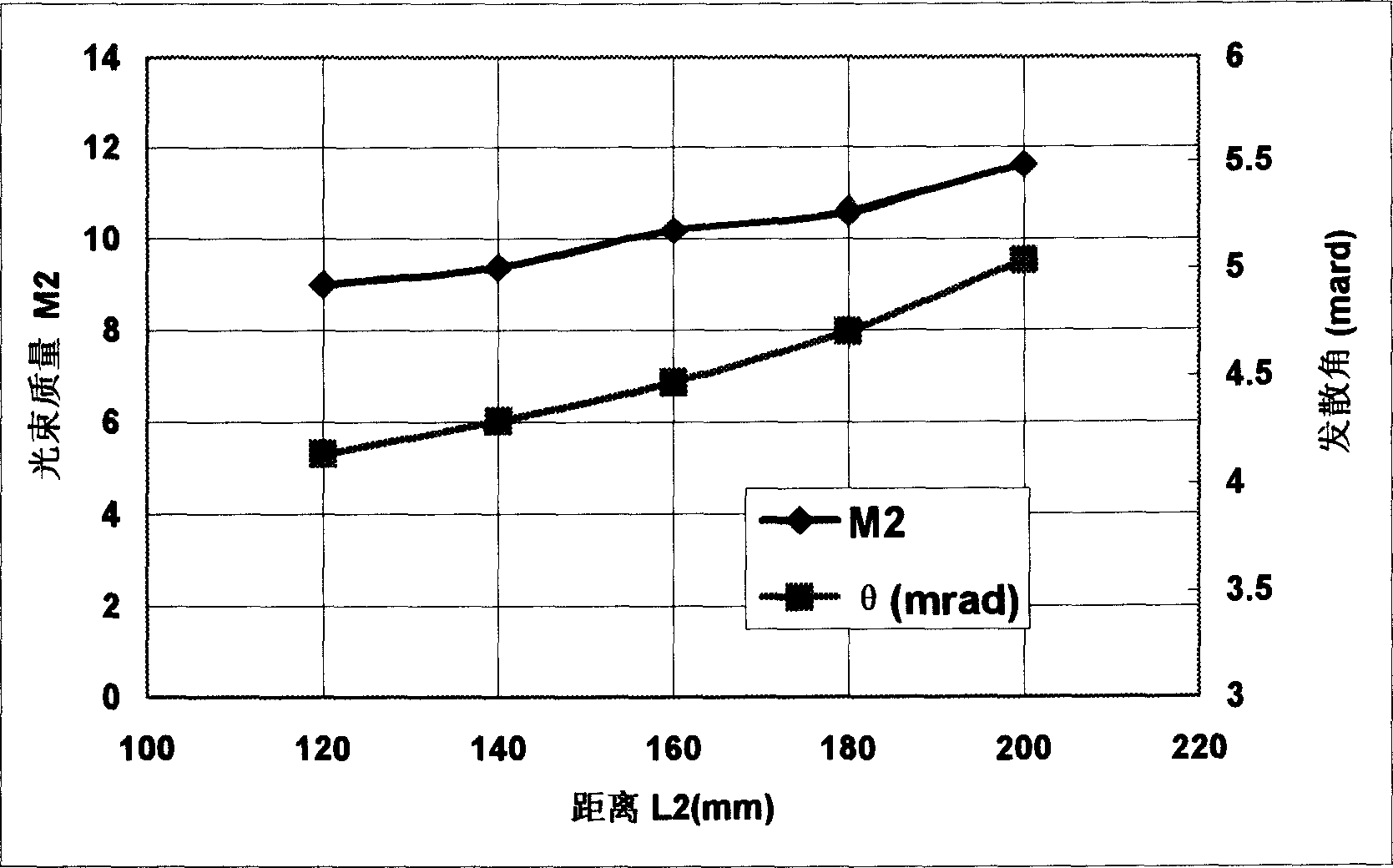

[0022] Such as figure 1 , figure 2 and image 3 As shown, by calculating the effect of the curvature of the convex cavity surface mirror on the beam quality and the incidence angle of the nonlinear crystal, the effect of the distance between the convex cavity surface mirror and the solid medium on the beam quality and the incidence angle of the nonlinear crystal, and the reflection of the flat cavity surface According to the influence of the distance between the mirror and the solid medium on the beam quality and the incident angle of the nonlinear crystal, the high-frequency-doubling-efficiency green laser generation method of the present invention is designed.

[0023] Such as Figure 4 As shown, the high frequency doubling efficiency green laser generation method of the present invention adopts a flat-convex "L" shaped resonant cavity, and the "L" shaped resonant cavity avoids the total inversion of the second harmonic inserted in the cavity relative to the straight shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com