Alkalescent water-quality treatment and treating system for double-internal water-cooled generator

A double-water internal cooling and water quality treatment technology, which is applied in the direction of adsorption water/sewage treatment, neutralization water/sewage treatment, ion exchange water/sewage treatment, etc. Independently adjust the pH value and conductivity of the inner cooling water to achieve the effect of reducing the corrosion rate and inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

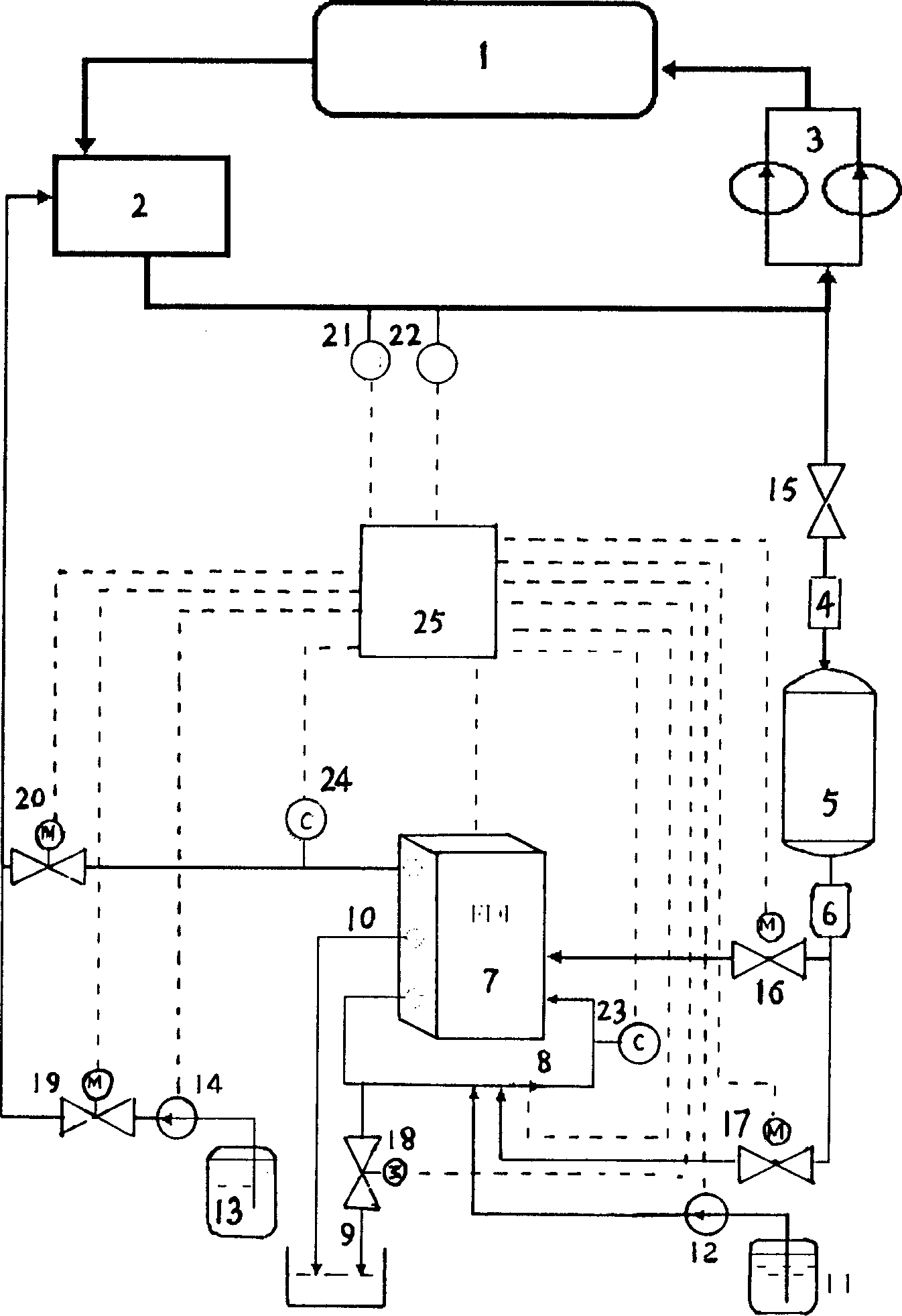

[0027] figure 1 is an embodiment of the present invention. The internal cooling water main circulation system of the generator is mainly composed of a generator 1, an internal cooling water tank 2, and an internal cooling water pump 3. Install a bypass system on the main circulation system. The bypass water flows sequentially through the resin trap 4, the cation exchanger 5, the precision filter 6, the EDI unit 7, and finally returns to the inner cooling water tank. The bypass water flow is controlled at 2-6t / h.

[0028]The resin filled in cation exchanger 5 can be strongly acidic cationic resin, weakly acidic cationic resin, chelating resin, NH 4 Type cation resin, Na type cation resin, K type cation resin. The amount of resin should be determined according to the parameters of the generator set and the characteristics of the internal cooling water system. In order to prevent clogging of the EDI unit, the index of the precision filter 6 is required to be no more than 2 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com