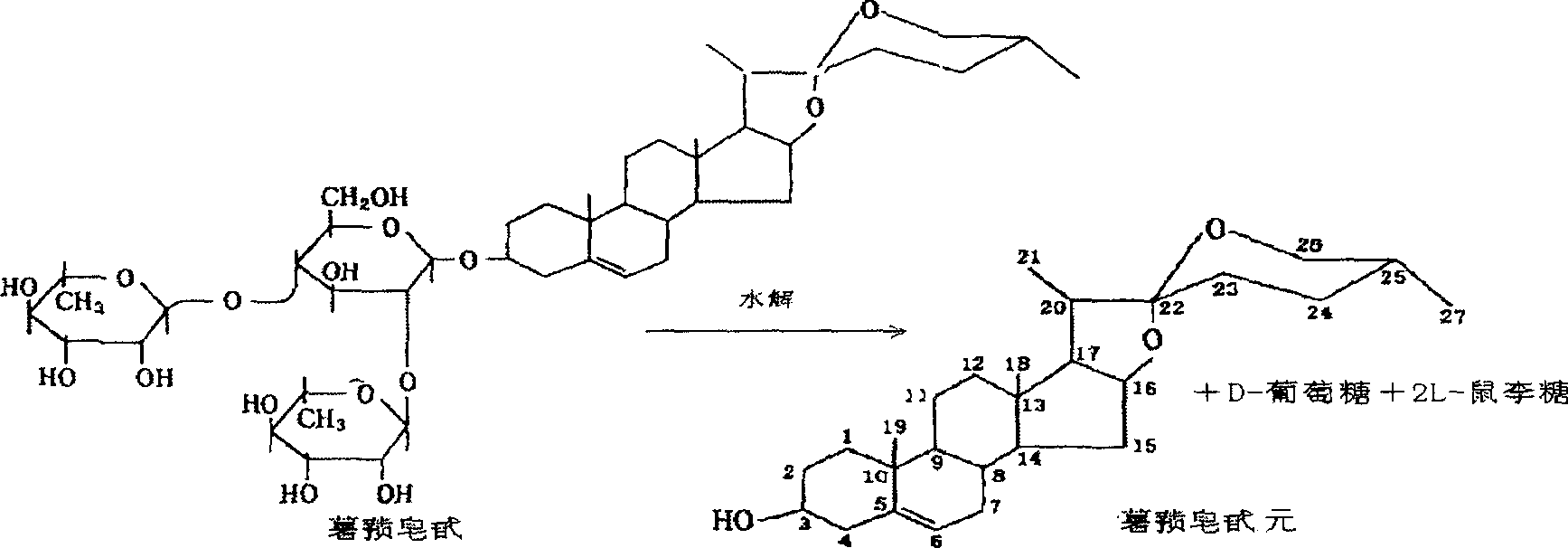

Preparation of yam saponine by hydrolysis of supercritical water

A technology of diosgenin and supercritical water, which is applied in the production of steroids, bulk chemicals, organic chemistry, etc., and can solve problems such as pollution and environmental products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Process and steps in the present embodiment are as follows:

[0020] (1) Get the average particle size of 50 meshes and mix 3 g of saponin dry powder made from 40 g of yam plant rhizome with water, and place it in a supercritical water device reactor; the weight ratio of dry powder to water is 1:50, that is, add 150 ml of water Heating in the reaction kettle to control the temperature of the supercritical water to be 250°C and the pressure to be 25MPa, so that the above-mentioned substances are hydrolyzed under the action of supercritical water;

[0021] (2) Stop heating after the hydrolysis reaction is carried out to 10 minutes, introduce the mixture in the supercritical state to condense in the coil condenser, and enter the sample collector after cooling down and depressurizing;

[0022] (3) Filter the condensed product in the collector, including the water phase and the solid phase, and retain the solid phase;

[0023] (4) Using ethanol as the extractant for the abo...

Embodiment 2

[0025] The process and steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is that 20ml of entrainer ethanol was added to the reaction kettle. Finally, 0.39 g of saponin was obtained, with a yield of 0.98% relative to the rhizome of the yam plant.

Embodiment 3

[0027] The process and steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is: the raw material put in the reaction kettle is 20g of dry root powder of yam plant, and the weight ratio with water is 1:8, that is, 160ml of water. Finally, 0.19 g of saponin was obtained, with a yield of 0.95% relative to the rhizome of the yam plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com