Preparation of deep grooves

A deep trench and trench technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that etching liquid is not easily transported to the lower half of deep trenches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

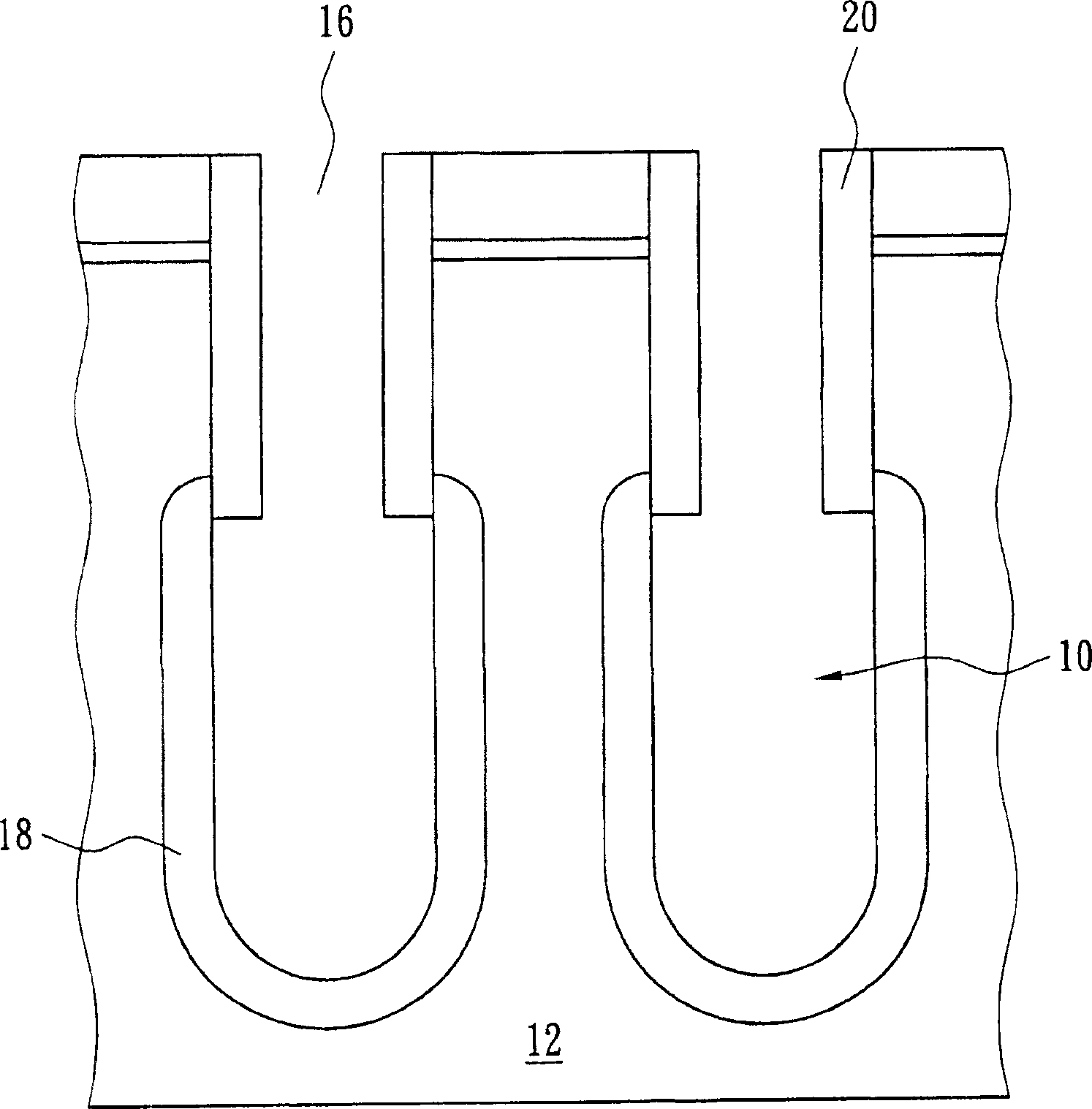

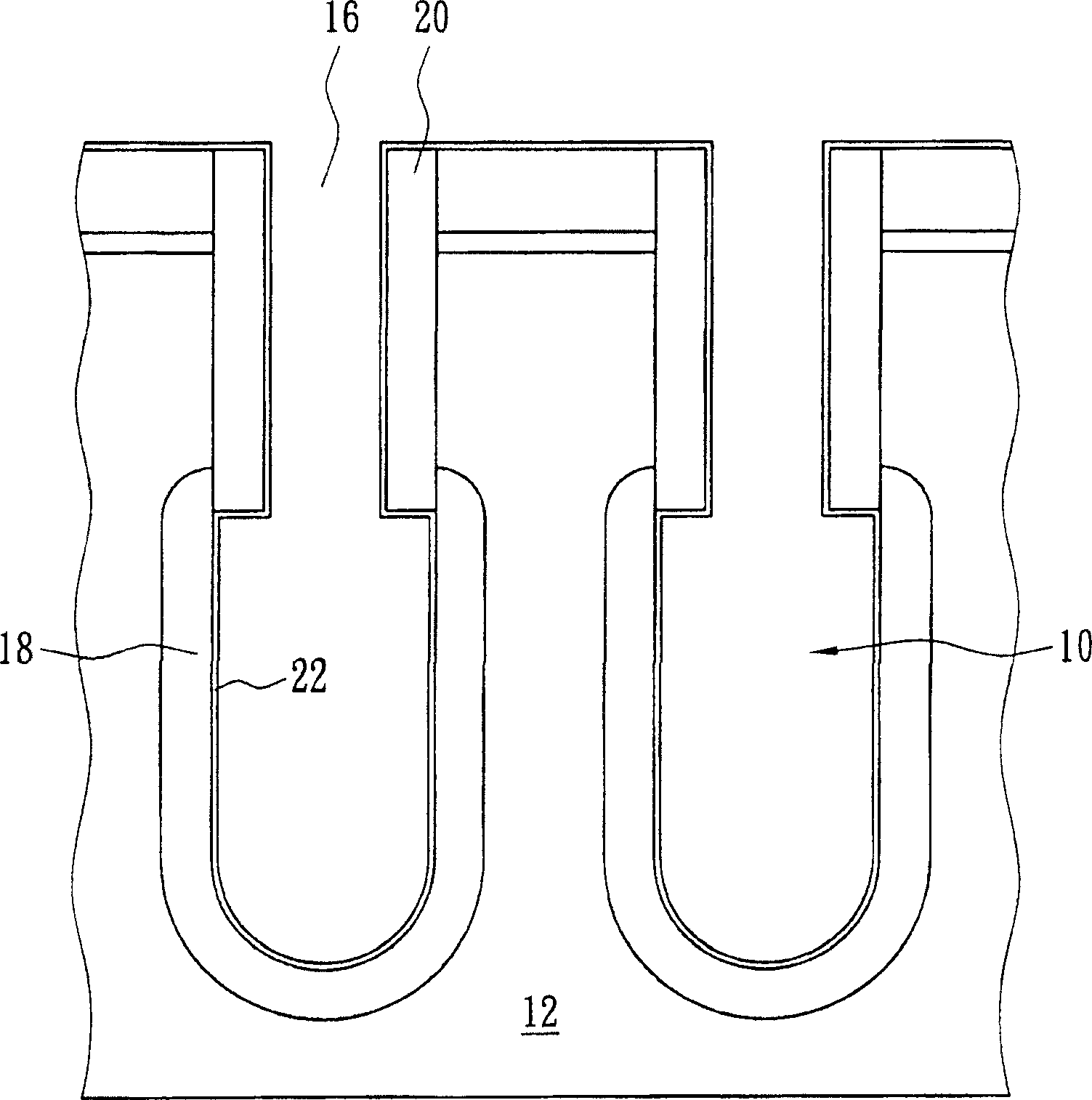

[0024] Figure 6 to Figure 11 The method of making a roughened deep trench 40 of the present invention is illustrated. First, two trenches 46 are formed in a substrate 42 . Generally speaking, countless grooves are usually formed on the substrate, which is only shown here for simplified illustration. Afterwards, an electrode 48 is formed on the outer edge of the lower half of the trench 46, and a ring-shaped oxide layer 44 is formed in the upper half of the trench 46 by thermal oxidation (or chemical vapor deposition) with anisotropic etching. edge surface.

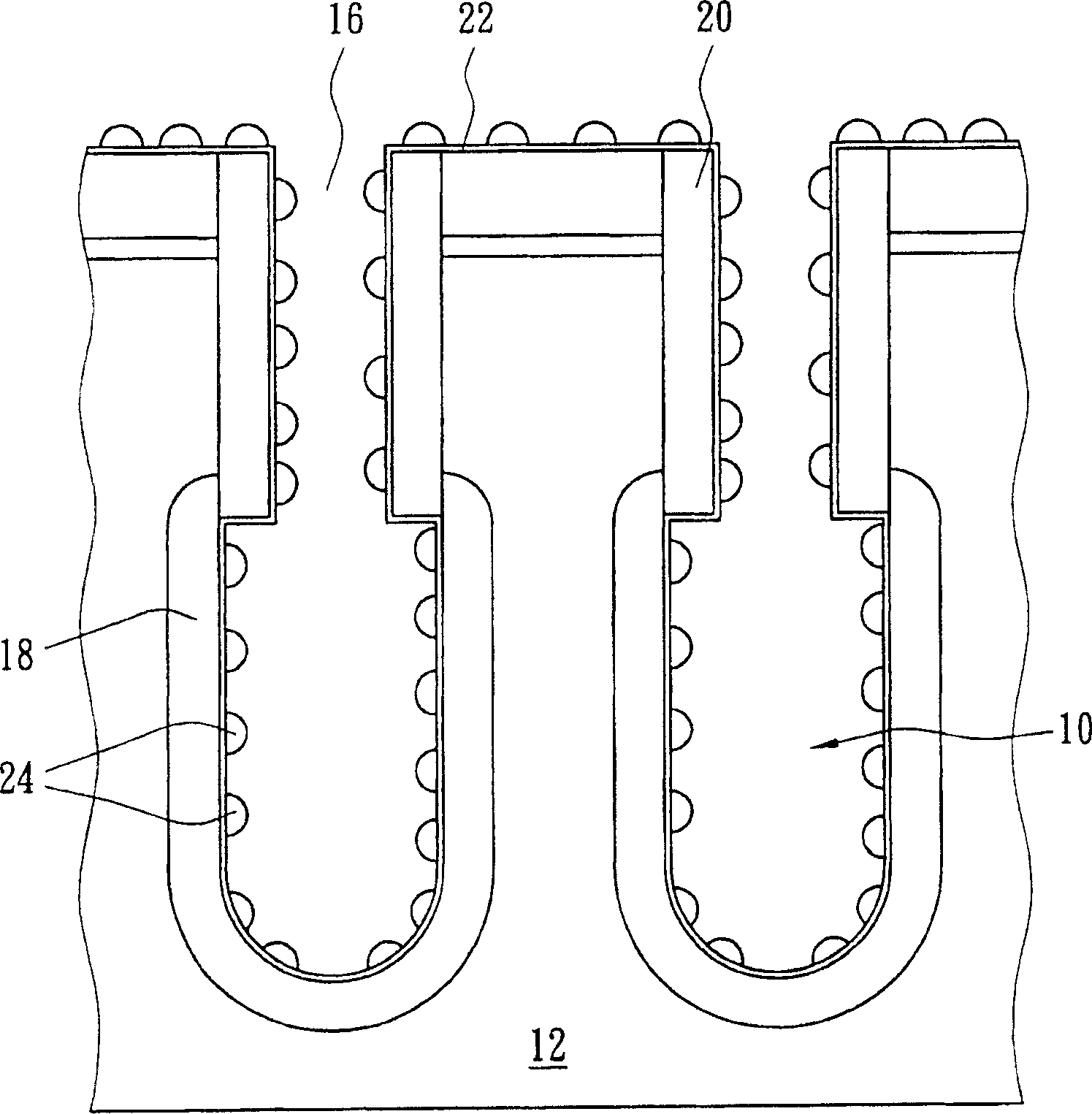

[0025] refer to Figure 7 , forming a nitrogen-containing layer 52 on the surface of the substrate 42 and the inner wall of the trench 46 by using a low pressure chemical vapor deposition process. After that, a plurality of crystal grains 54 are formed, which cover the partial surface of the nitrogen-containing layer 52, such as Figure 8 shown. The grains 54 may be polysilicon grains with a size between 15-30 nm, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com