Burning utilizing method for super low concentration combustible gas

An ultra-low concentration, gas technology, applied in combustion equipment, steam boilers, steam generation, etc., to achieve the effect of simple installation, recovery and environmental protection, and reduction of construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

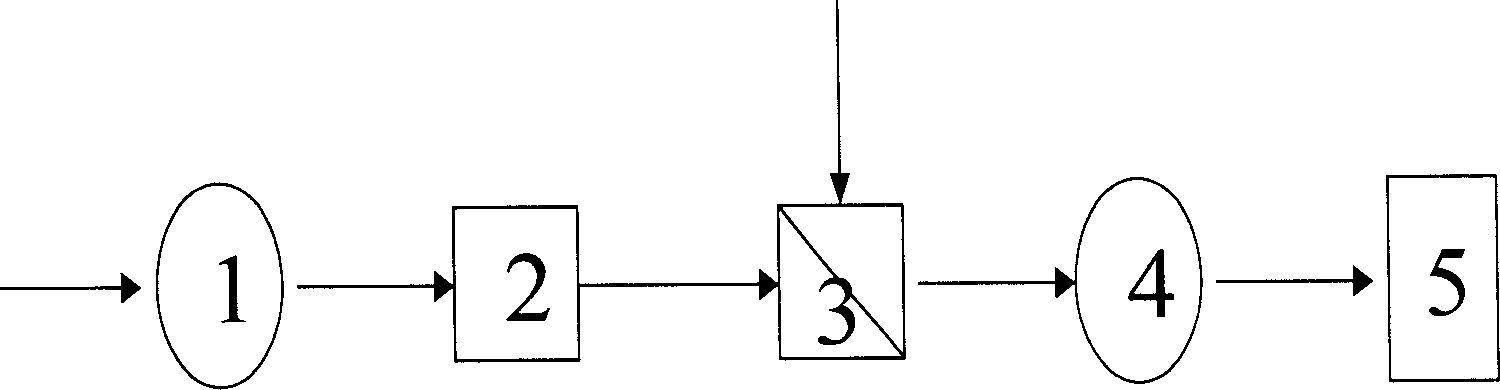

Image

Examples

Embodiment Construction

[0013] The combustible gas referred to in the present invention includes: coal mine ventilation exhaust gas with a methane concentration of less than 1%, ultra-low concentration methane discharged from the process of methane generation, and various chemical and metallurgical processes that cannot be used at room temperature. Ignite ultra-low concentration flammable gas.

[0014] The combustion utilization method of the ultra-low concentration combustible gas provided by the present invention is to transport the combustible gas to the air inlet of the combustion equipment through the pipeline, and the combustion-supporting air as the main fuel enters the combustion chamber of the combustion equipment for combustion; In view of the impact of previous explosion accidents on combustion equipment, explosion-proof devices should be installed in the combustible gas delivery pipeline; at the same time, in order to improve the safety performance of the system, a switch between ultra-low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com