Stepping-in axial vibration drilling technique and apparatus therefor

An axial vibration, step-by-step technology, used in metal processing equipment, drilling/drilling equipment, portable drilling rigs, etc., can solve the difficulty of parameter selection and optimization and the increase in workload, complicated control and optimization, and processing technology. Complex problems, to achieve the effect of simplifying the workload of parameter selection and optimization, convenient operation, and simple equipment production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

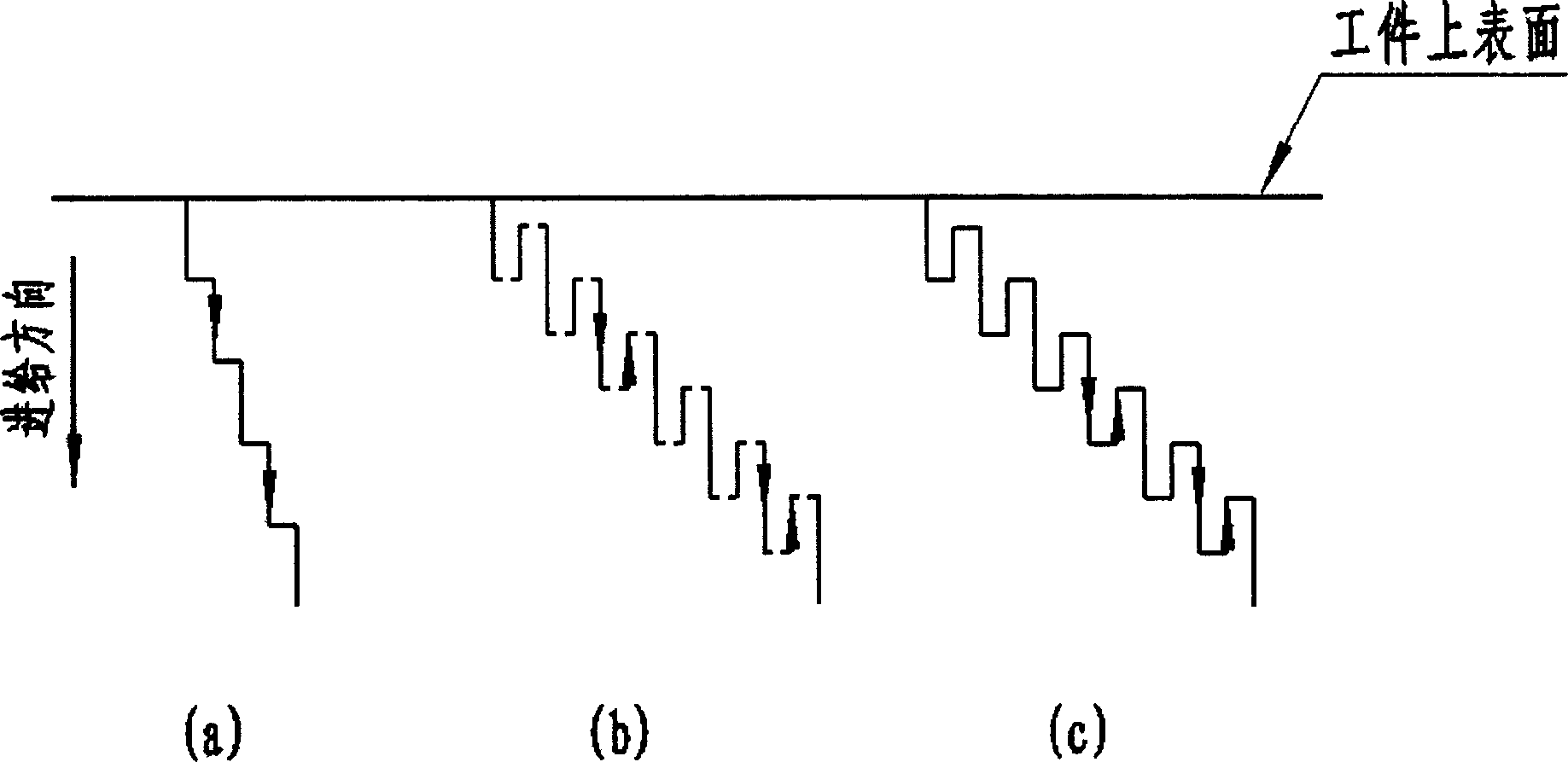

[0027] The present invention is a step-by-step axial vibration drilling process and equipment. "Instead, the axial movement characteristics of the drill bit are controlled by adjusting the pulse frequency and vibration shape of the stepper motor, and different vibration processing modes can be selected according to processing needs. This process simplifies the operation process of axial vibration drilling and expands the technological range of vibration drilling.

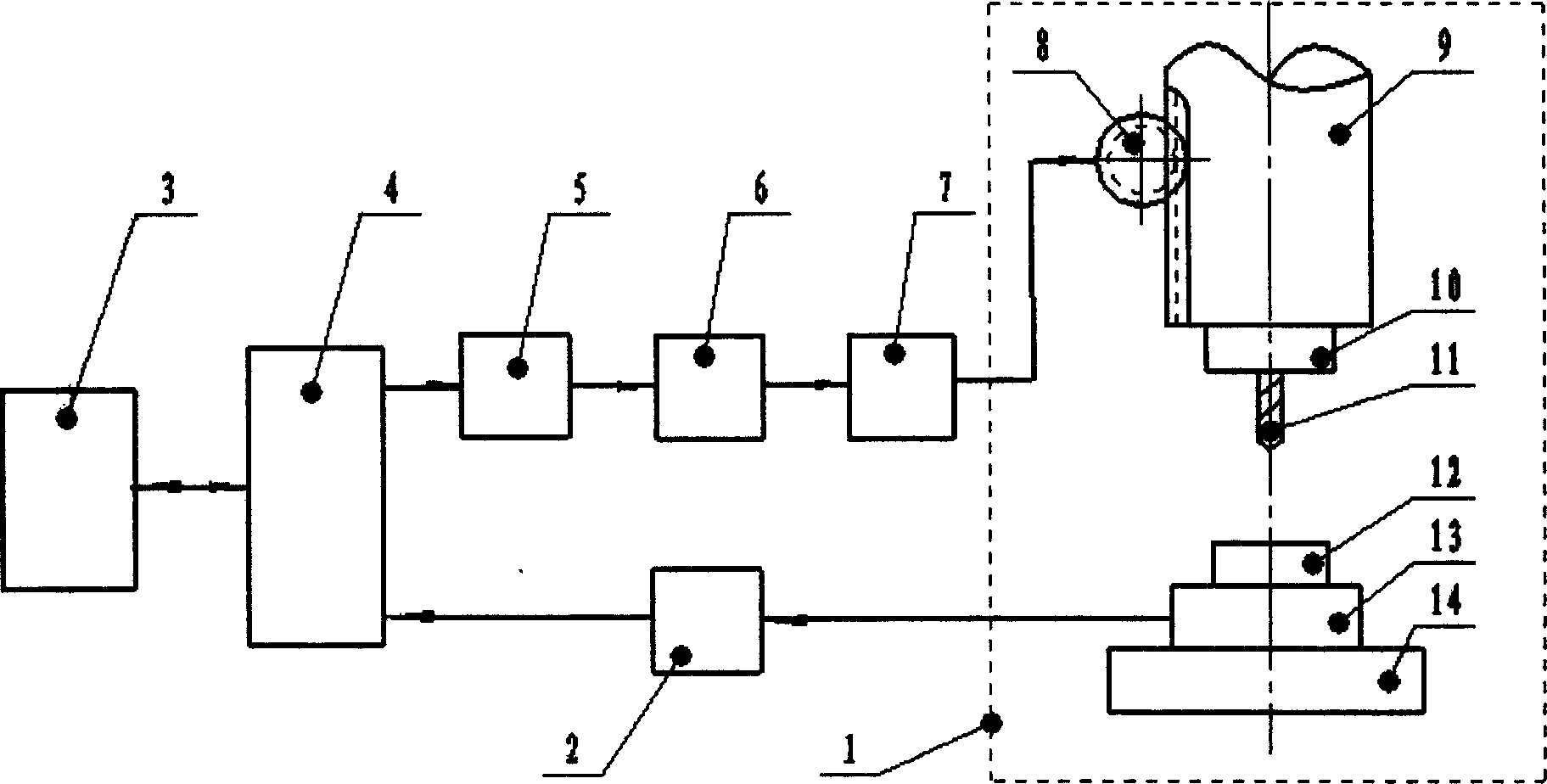

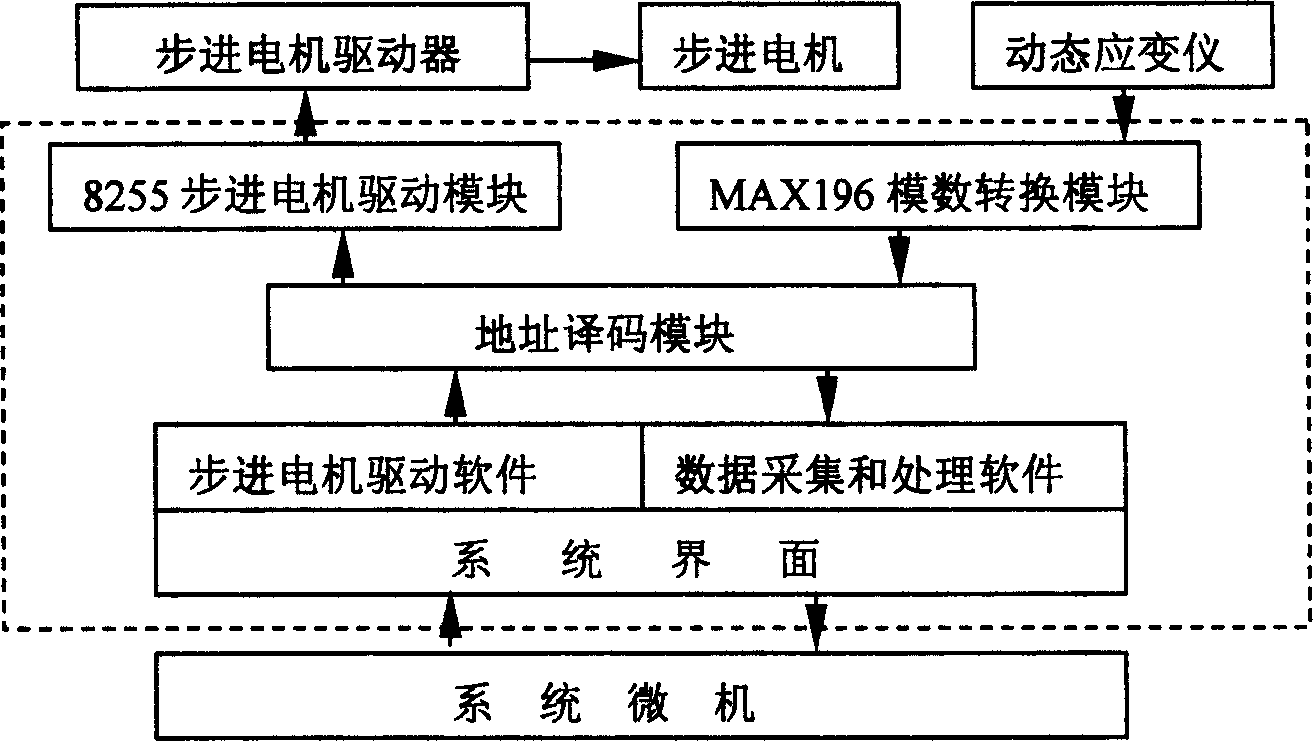

[0028] Such as figure 2 As shown, the equipment for realizing this process is mainly composed of machine tool body 1, dynamic strain gauge 2, system microcomputer 3, hardware interface circuit 4, stepper motor driver 5, stepper motor 6, reduction mechanism 7, and drilling dynamometer 13 ,

[0029] Wherein hardware interface circuit 4 mainly comprises address decoding module, 8255 stepper motor drive module, MAX196 analog-to-digital conversion module, and it adopts ISA bus technology, directly makes interface card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com