Preparation of distributed optical fiber sensor reflector

A technology of distributed optical fibers and mirrors, applied in the directions of light guides, optics, instruments, etc., can solve the problems of high cost of fiber grating equipment, grating response function errors, complex additional conditions, etc., and achieve the effect of easy operation and simple mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The manufacture of a novel distributed optical fiber sensor reflector of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

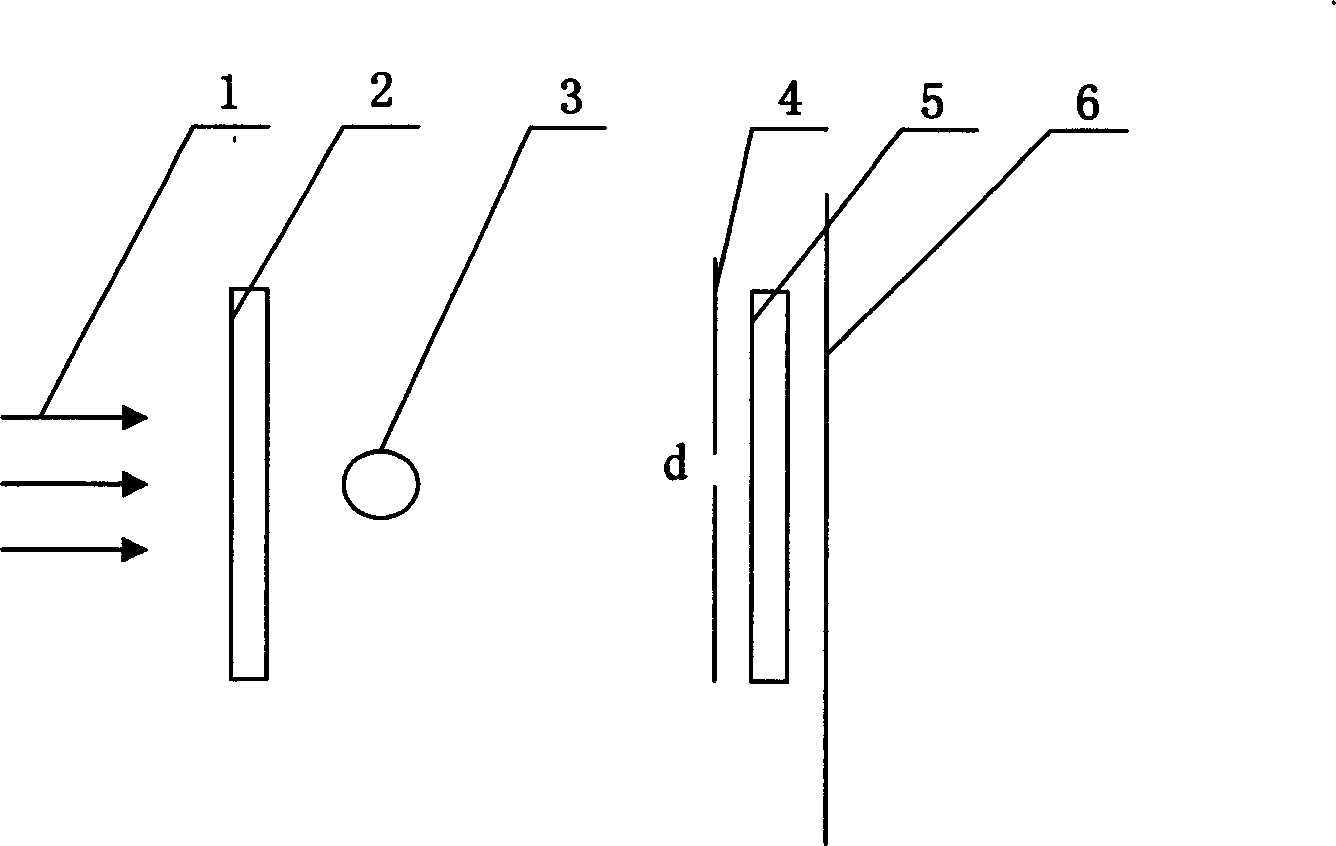

[0024] Such as figure 1 As shown, the manufacture of a novel distributed optical fiber sensor reflector of the present invention includes an ultraviolet laser 1, a cylindrical lens 2, a cylindrical lens 3, a phase template 5, and a slit plate 4. The overall configuration structure is: The ultraviolet laser 1, the cylindrical lens 2, the cylindrical lens 3, the slit plate 4, and the phase template 5 are arranged in sequence.

[0025] Wherein, the ultraviolet laser 1 is selected from one of a 139nm argon ion laser or a 248nm excimer laser.

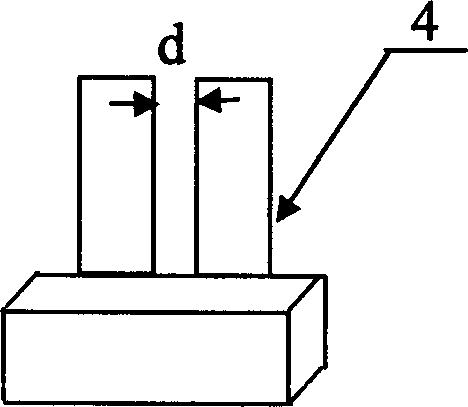

[0026] Such as figure 2 As shown, the slit plate 4 is made of a metal material with good thermal conductivity, its slit width d is adjusted according to the bandwidth width of the fiber grating reflector required, and the slit width d is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com