Thin film for package of alkaline battery and thin air battery using the same

An air battery and air electrode technology, which is applied to fuel cell-type half-cells and primary cell-type half-cells, battery electrodes, and batteries/batteries that work under specific conditions, etc. Large battery and other problems, to achieve the effect of inhibiting the penetration of water vapor into and out of the battery, preventing self-discharge, and high long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

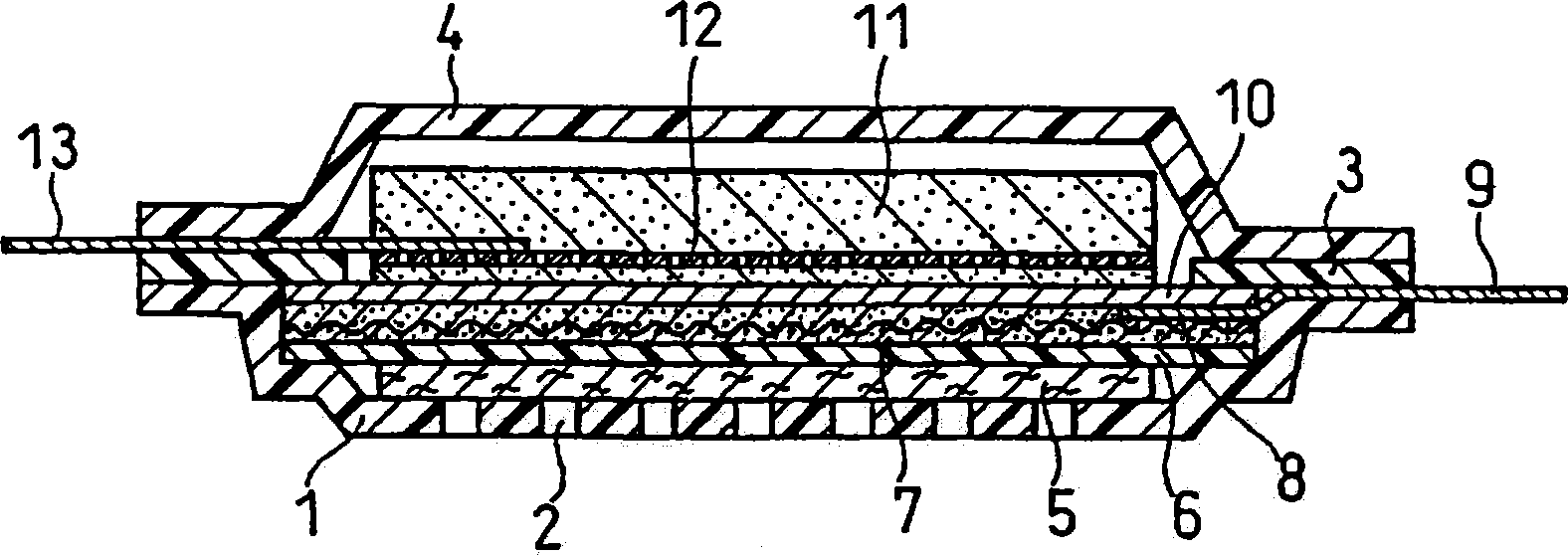

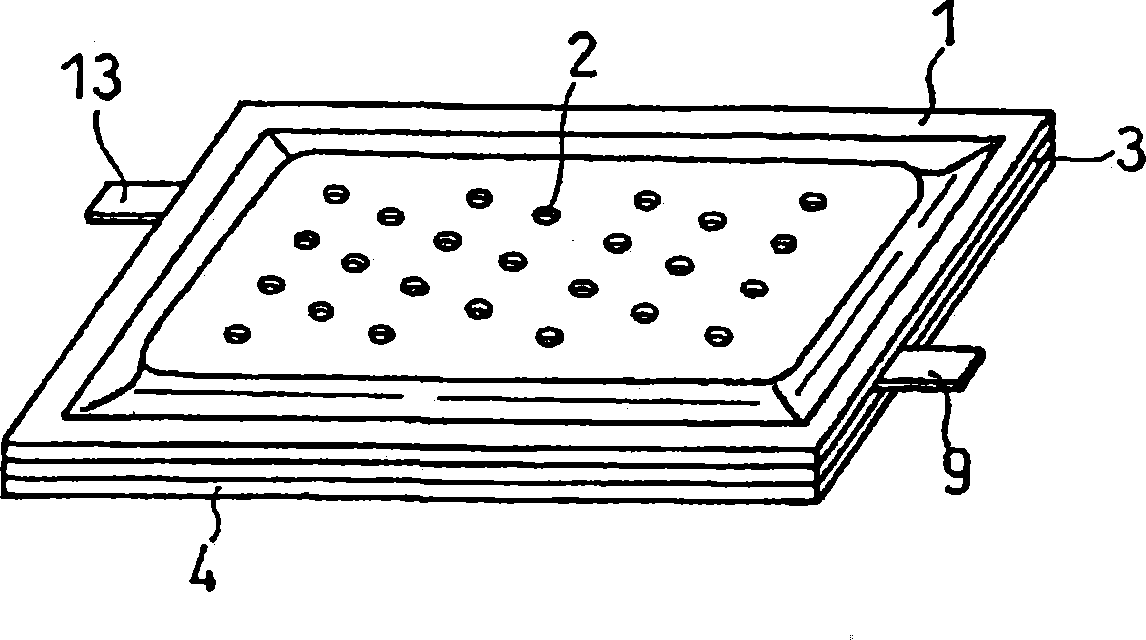

[0052] For the sheets 1, 3 and 4 of the casing, modified polypropylene (PPa) with a thickness of 0.02 mm was used as the hydrogen gas permeable material, PEN with a thickness of 0.035 mm was used as the gas barrier material, and a three-layer structure was used. The total thickness of the composition was a sheet of 0.075 mm in which both surfaces of PEN were coated with PPa (thin sheet film (PPa-N), manufactured by Dai Nippon Printing Co., Ltd.).

[0053]The first sheet 1 was stretched to have a depth of 0.6 mm using hot pressing. In the depression, vinylon fiber paper (thickness: 0.1 mm) was placed as an air-permeable paper 5 to cover the air intake hole 2, and spots were bonded with resin to be fixed. On the vinylon fiber paper, a fine porous film of polytetrafluoroethylene (PTFE) (thickness: 0.1mm) as the waterproof membrane 6, an air electrode 7 (thickness: 0.3mm), and polypropylene as the separator 10 are laminated in this order. (PP) fine porous film (thickness: 0.05mm)...

Embodiment 2~14

[0061] The hydrogen gas permeable material, the gas barrier material, and the metal material, the thickness thereof, the composition and the thickness of the casing composed of these materials are shown in Table 1. By uniformly and fully rolling-coating modified polybutadiene whose thickness is substantially negligible on the surface of the gas barrier material sheet as a coating cement, and bonding the hydrogen gas permeable material to it, the hydrogen gas permeable material and the gas barrier Materials bond to each other. A thin air battery was fabricated in the same structure as in Example 1 except for using those described above.

[0062] hydrogen permeable material

Embodiment 15~18

[0064] Acid-modified polypropylene (PPa) having a thickness of 0.02 mm was used as the hydrogen gas permeable material, and a fluorine-containing polymer material was used as the gas barrier material, and the combination of its structure and its thickness are shown in Table 1. The surface of the fluorine-containing polymer material sheet is surface-modified by corona discharge, and the surface of the fluorine-containing polymer material sheet is roll-coated with modified polybutadiene as a coating cement, and the The hydrogen permeable material is bonded to the coating surface such that the hydrogen permeable material is bonded to the fluorine-containing polymer material. A thin air battery was fabricated in the same structure as in Example 1 except for using those described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com