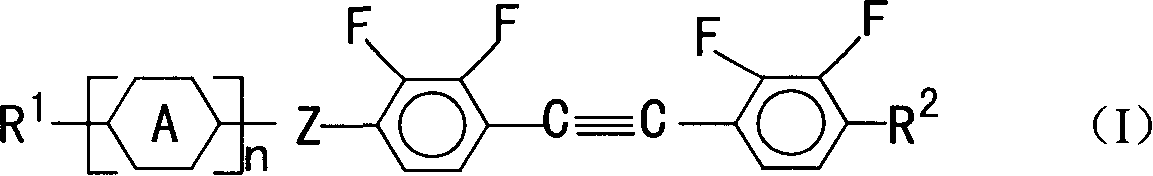

2,3,2,'3' tetrafluoro diphenyl acetylene derivative, its composition, preparation method and use

A technology of tetrafluorotoluene and its derivatives, which is applied in 2 fields and can solve problems such as insufficient effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

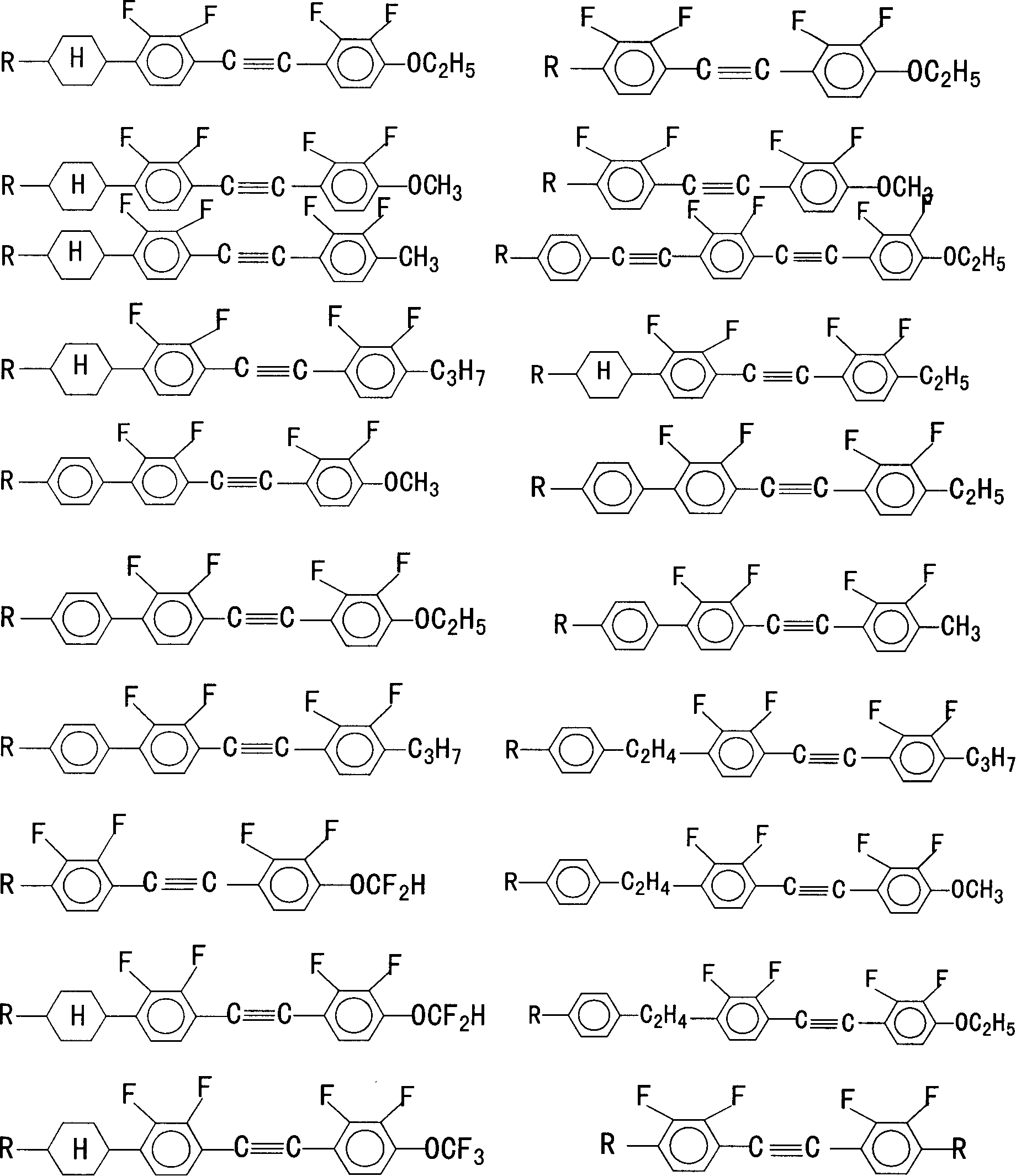

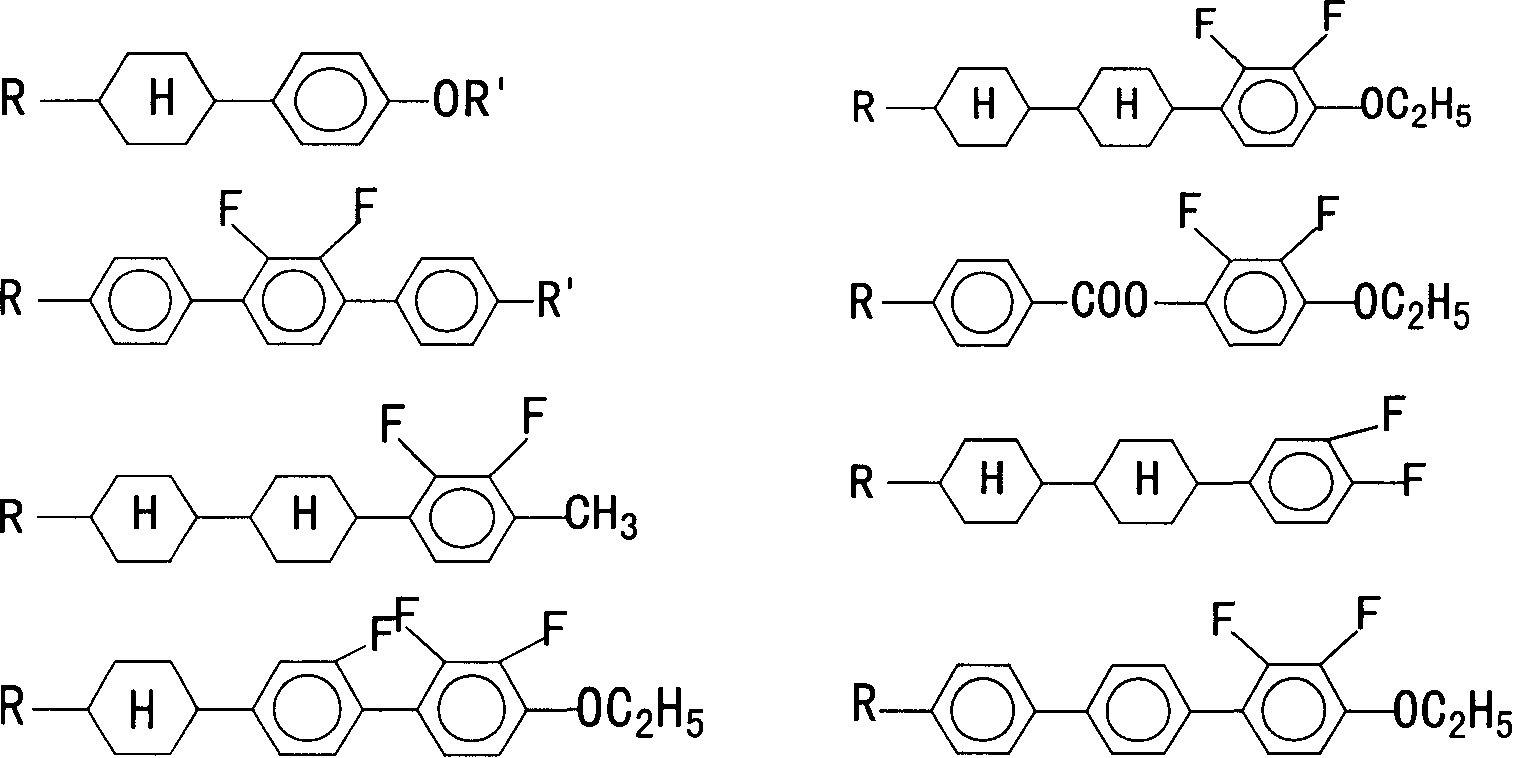

Image

Examples

Embodiment 1

[0094] Preparation of 4-propyl-4`-ethoxy-2,3,2`,3`-tetrafluorobenzil.

[0095]

[0096] Step 1-1: Synthesis of 4-ethoxy-2,3-difluoroiodobenzene: Add 52g (0.37mol) 2,3-difluorophenetole, 250ml dry tetrafluorofuran into a three-necked flask, and lower the temperature under nitrogen protection At -70°C, start to add 0.45mol of n-butyllithium dropwise for about half an hour. After the addition is complete, keep it at -70°C for 1.5 hours. Add dropwise for 1 hour, after dropping, keep for 1 hour; slowly add 10% NaHSO 3 Solution until discolored, separated, the organic layer was washed twice with water, anhydrous MgSO 4 Dry, filter off the desiccant, evaporate to dryness to obtain 88g, gas chromatography purity: 95%, yield: 81%.

[0097]Step 2-1: Synthesis of 4-propyl-2,3-difluoroiodobenzene: Add 117g (0.75mol) propyldifluorobenzene and 600ml dry THF into a three-necked flask, and cool down to -70°C under nitrogen protection Start to add 0.9 mol of n-butyllithium dropwise, cont...

Embodiment 2

[0105] Preparation of trans-4-propylcyclohexyl-4`-ethoxy-2,3,2`,3`-tetrafluorobenzil.

[0106]

[0107] Step 1-1: Synthesis of propylcyclohexene-2,3-difluorobenzene: Add 114g (1mol) of o-difluorobenzene and 300ml of dry THF into a three-necked flask, install and stir, cool down to -70°C under nitrogen protection, and start Add 1.1mol of n-butyllithium dropwise, control the temperature at -70°C, add dropwise for about 1 hour, after dropping, keep for 1 hour, then add 126g (0.9mol) of acetone dropwise at -70°C Add dropwise for about 1 hour, and keep for 4-5 hours after the drop is completed. Pour into about 1.5L of water for hydrolysis, extract with 500ml×3 toluene, combine organic phases, wash with water until neutral, divide into clean water, add another three-neck flask, add 5g of p-toluenesulfonic acid, heat up while stirring, and distill THF , when the internal temperature reaches 108°C, stop the distillation, change to a reflux condenser, and reflux for 5-6 hours. Aft...

Embodiment 3

[0120] Preparation of trans 4-pentylcyclohexyl-4`-ethoxy-2,3,2`,3`-tetrafluorobenzil

[0121]

[0122] With reference to the synthetic method in Example 2, the difference is that the acetone in step 1-1 is replaced with pentanecyclone, reacted with 2,3-difluorophenyllithium reagent, and undergoes dehydration, hydrogenation, transposition, Iodination gives 4-pentylcyclohexyl-2,3-difluoroiodobenzene, which is then coupled with 4-ethoxy-2,3-difluorophenylacetylene, and its total yield is 38%. The experimental results are as follows:

[0123] (1) Assay by gas chromatography: >99.7%.

[0124] (2) Compound phase structure: C: 84.5°C N: 208.7°C I. I

[0125] molecular formula

Characteristic ions (M / Z + ) and abundance (%)

C 27 h 30 f 4 o

446(M+,100),390(14.80),305(5.78),292(42.71),279(20.15),266(9.78),

[0126] Elemental analysis:

[0127] Theoretical calculated values: C: 72.63%, H: 6.77%.

[0128] Experimental values: C: 72.61%, H: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com