Method for decoating on waste plastic metal

A metal coating and waste plastic technology, applied in the field of waste metal recycling, can solve the problems of high recycling cost, high cost of metal coating, and difficulty in recycling valuable metals, and achieve effective utilization, low cost, economic and social benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

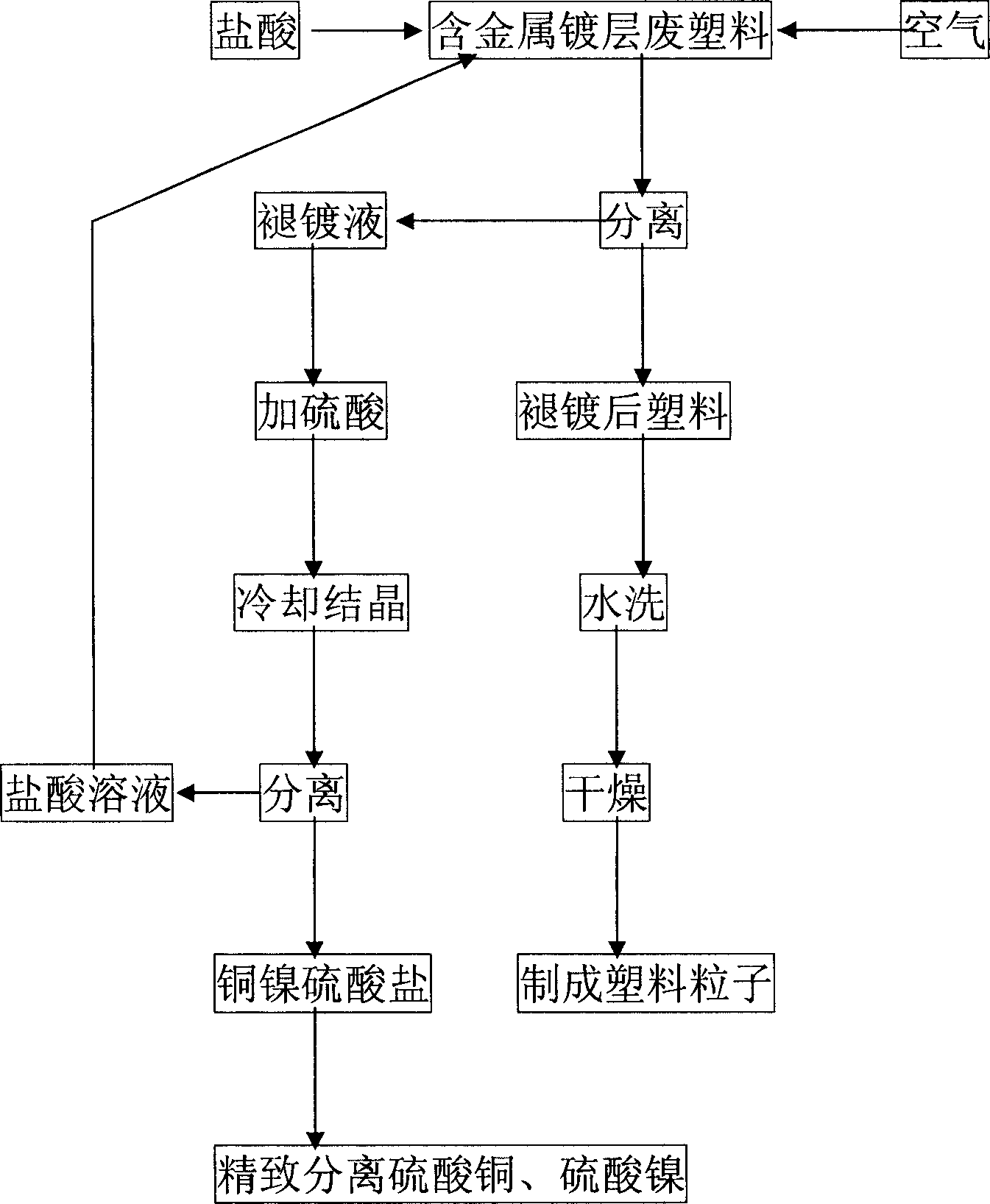

[0014] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0015] Put waste plastics mainly containing metal copper, nickel and chromium plating into the raw material hydrochloric acid solution, and fill in air at the same time to fully react the hydrochloric acid and the metal plating to generate a deplating solution containing copper chloride, nickel chloride and chromium chloride And the plastic after deplating; separate the deplating solution and deplating plastic produced, and recycle the deplating plastic into plastic particles after washing and drying; add sulfuric acid to the deplating solution after separation, sulfuric acid and deplating solution The metal chloride salt reacts to generate copper sulfate, nickel sulfate and hydrochloric acid, and the reacted mixed solution is cooled and crystallized to obtain copper sulfate and nickel sulfate crystals, and then separated by filtration to obtain copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com