Solvent in use for purifying products in anthracene series in crystal level

A product and crystallization technology, applied to the separation of heterocycles, can solve the problems of poor washing separation ability, infeasibility, and low yield, and achieve the effect of improving washing separation ability, improving purification effect, and improving separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The solvent used for crystallization and purification of anthracene series products provided by the invention is prepared by reacting crude benzene with hydrogen and then distilling.

[0019] Compare with prior art by using a specific embodiment of the present invention below, illustrate the beneficial effect of the present invention:

[0020] In the prior art, the solvent FO (anthracene-carba solvent oil) is used to wash and crystallize the anthracene segment AATO of the tar to obtain the intermediate product FACO (anthracene-carba crystallization product), which is then distilled under reduced pressure to produce a carbazole content of about 90%. carbazole products, but the quality of the carbazole products can not be further improved, and the yield is only about 50%, so that the purity of the carbazole products cannot meet the product quality requirements.

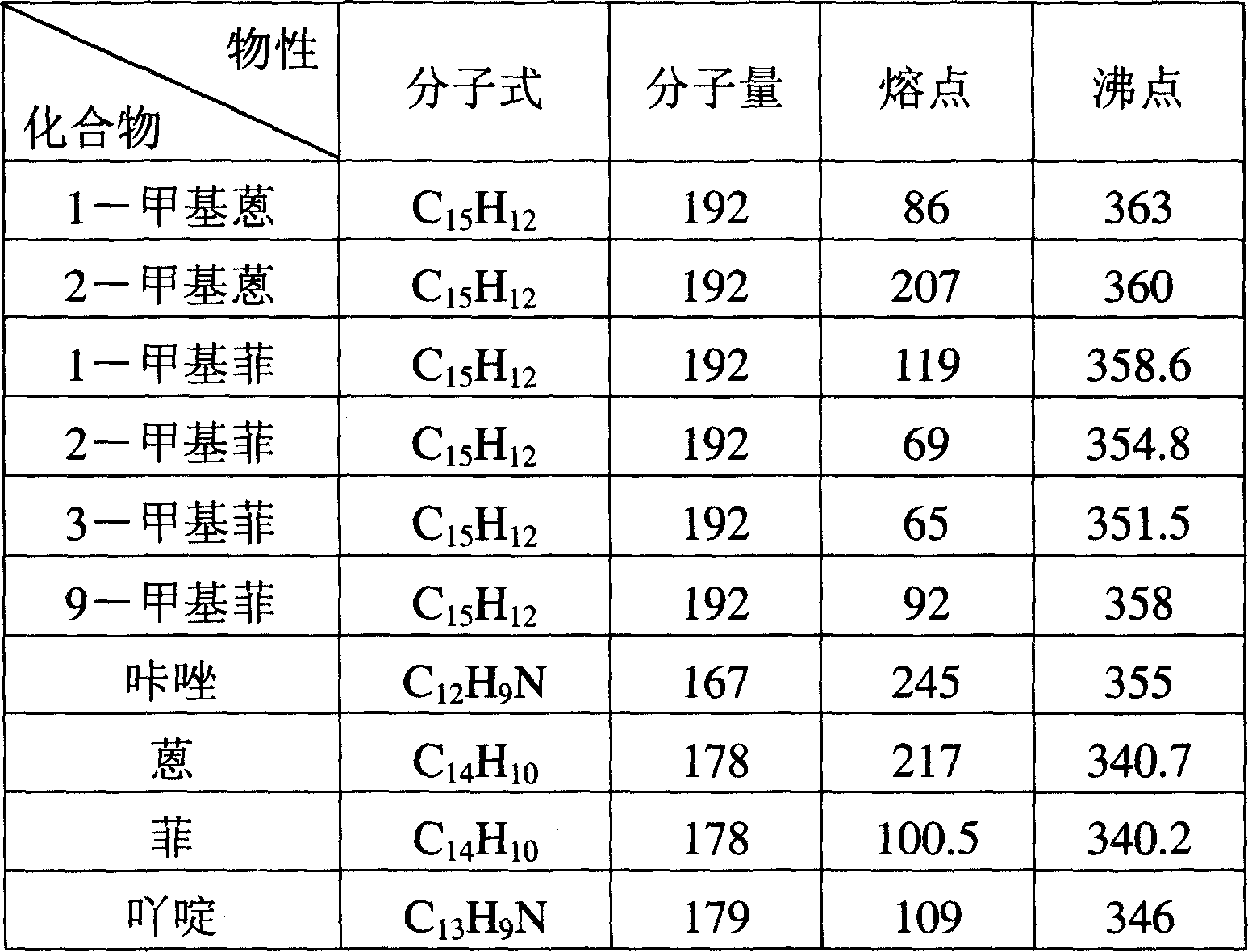

[0021] Judging from the product composition of the carbazole product obtained, it contains 2 kinds of impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com