Method of full-automatic vibration processing work-piece by frequency spectrum analysis

A technology of vibration processing and frequency spectrum analysis, which is applied in the field of vibration stress relief, can solve the problems that the workpiece cannot be processed by vibration, and the vibration noise is large, so as to achieve the effect of eliminating residual stress, eliminating the effect and ensuring the constancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

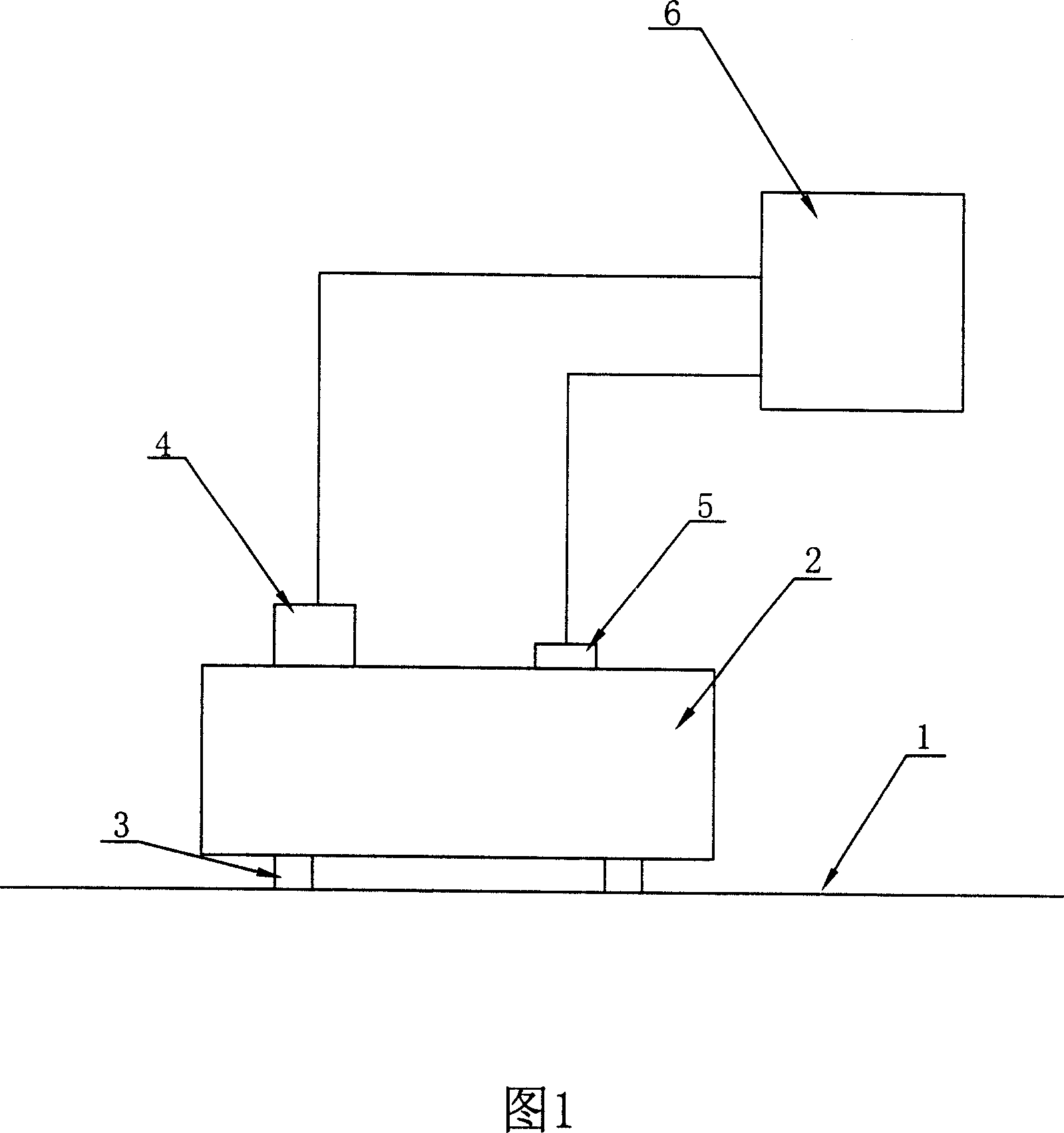

[0036] As shown in Figure 1, the workpiece (2) is supported on the foundation (1) through an elastic support, such as a shock absorbing pad (3), and the vibrator (4) is rigidly fixed on the workpiece (2) except for weak points ( Such as the arbitrary position of position such as big sheet plane), acceleration sensor (5) is placed on the workpiece (2) and is far away from the arbitrary position of exciter, and exciter (4) and acceleration sensor (5) are also respectively connected with including single-chip microcomputer , the software system and the controller (6) of the control key are connected.

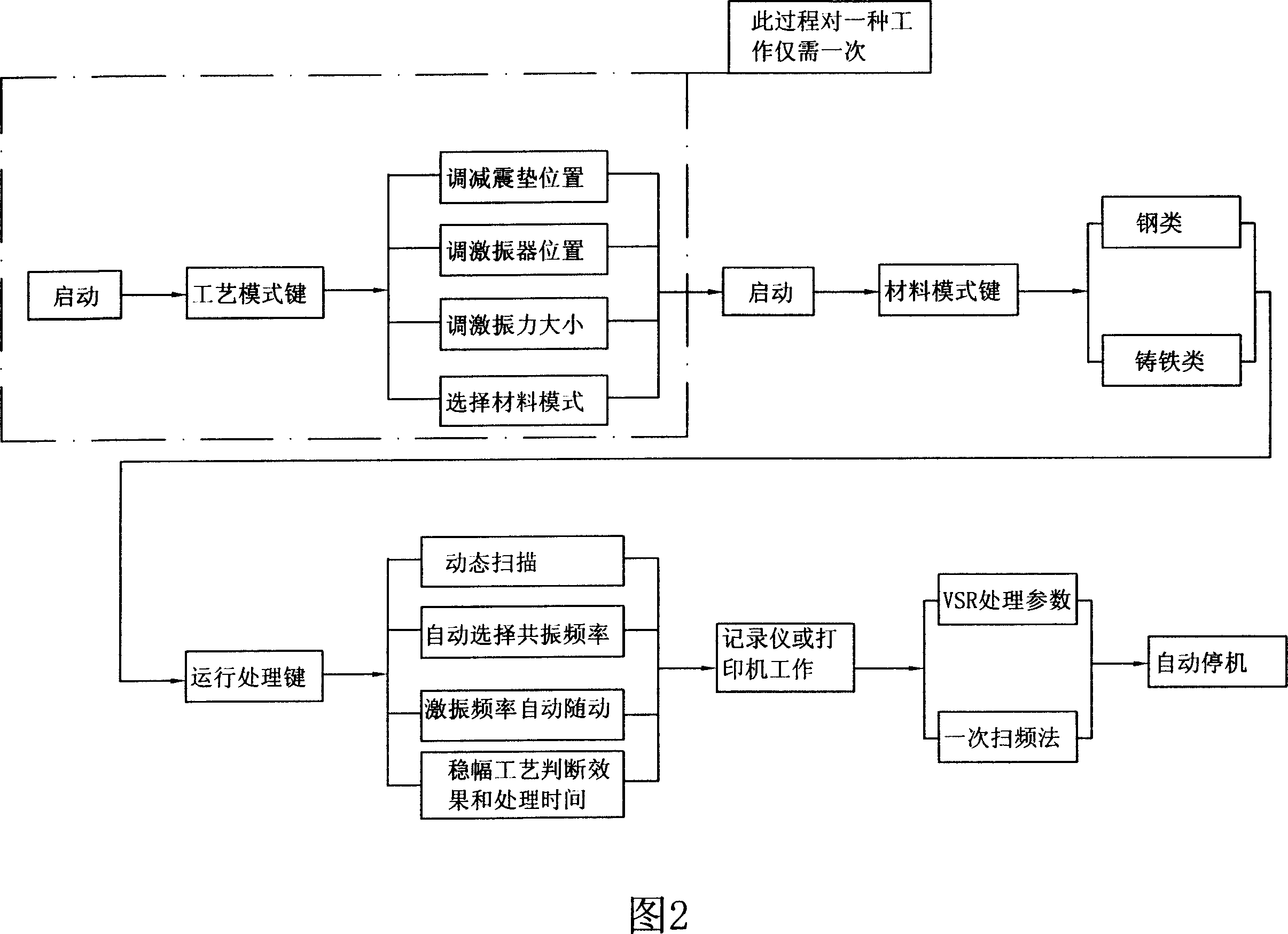

[0037] As shown in FIG. 2 , it is a step-by-step flowchart of a method for eliminating vibration stress of a workpiece in the prior art, and the method includes a workpiece processing preparation process and a workpiece processing operation process. The steps of the workpiece processing preparation process are: press the "Start" button to start the VSR device, press the "Technology...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com