Liquid crystal display drive circuit

A liquid crystal driving circuit and driving voltage technology, applied in the direction of logic circuit connection/interface layout, optics, instruments, etc., can solve the problems of large through current or charging and discharging current, driving voltage and voltage fluctuation, and chip size influence, etc. Prevents shoot-through current from flowing through the output transistors, reduces the number, and realizes the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

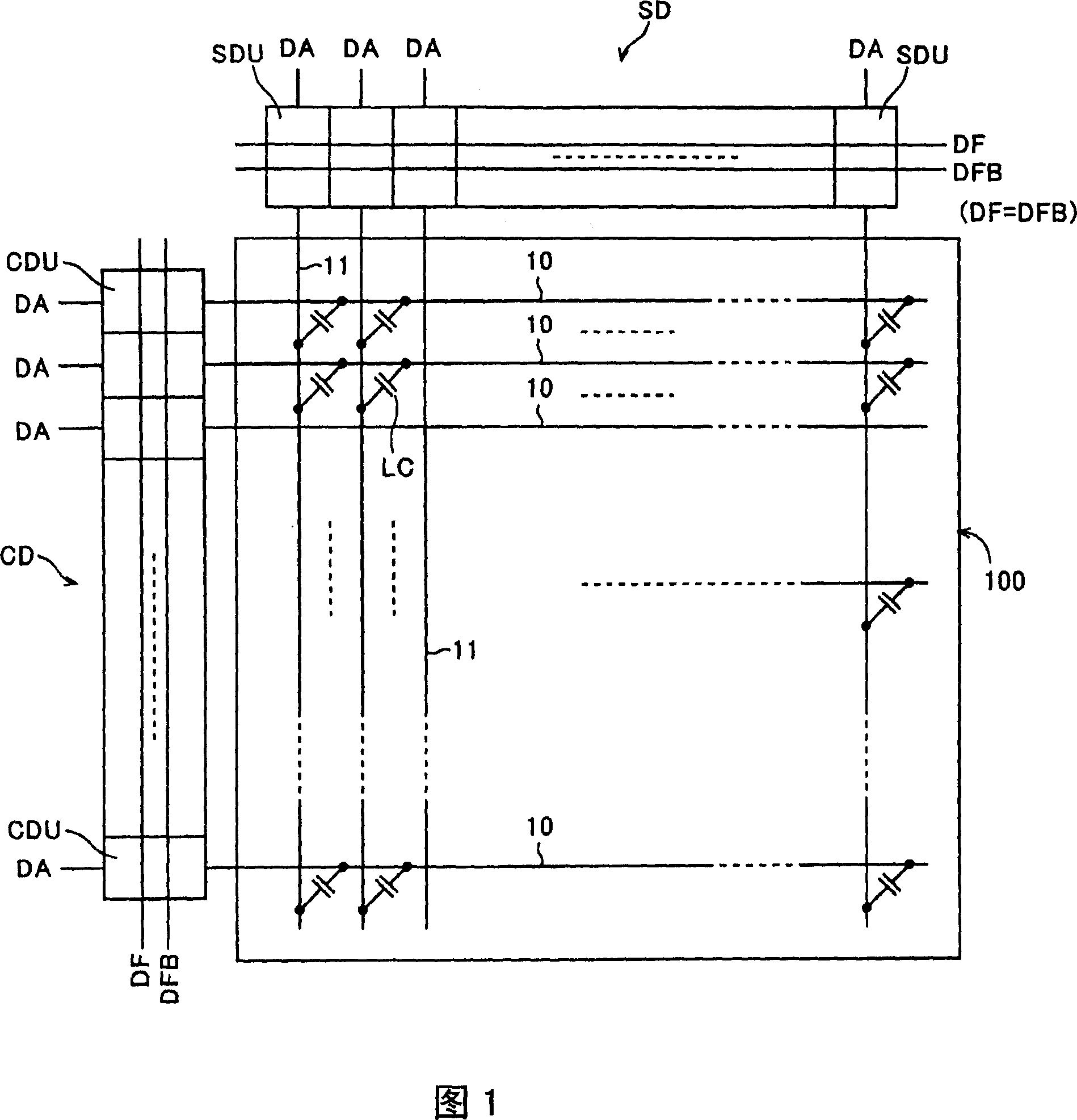

[0022] Next, embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a diagram showing the structure of a dot matrix type STN-LCD panel. In this STN-LCD panel, a common driver CD and a segment driver SD are provided around the display area 100 . The common driver CD has a plurality of common drivers / units CDU with the same circuit structure. In each driver / unit CDU, a dot signal DA, a field signal DF common to each driver / unit CDU, and an inverted field signal DFB are supplied. The segment driver SD also has a plurality of segment drivers / units SDU with the same circuit configuration, but the field signal DF and the inverted field signal DFB are set to the same signal.

[0023] Output signals of the driver / unit CDU are output to corresponding row lines 10 , and output signals of the segment driver / unit SDU are output to corresponding column lines 11 . A liquid crystal capacitor LC is formed at each intersection of the row line 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com