Waste gas purifier

A technology of exhaust gas purifier and exhaust gas purification device, which is applied in chemical instruments and methods, exhaust devices, machines/engines, etc., can solve the problems of short service life of exhaust gas purification device and reduced ability of separation and purification treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

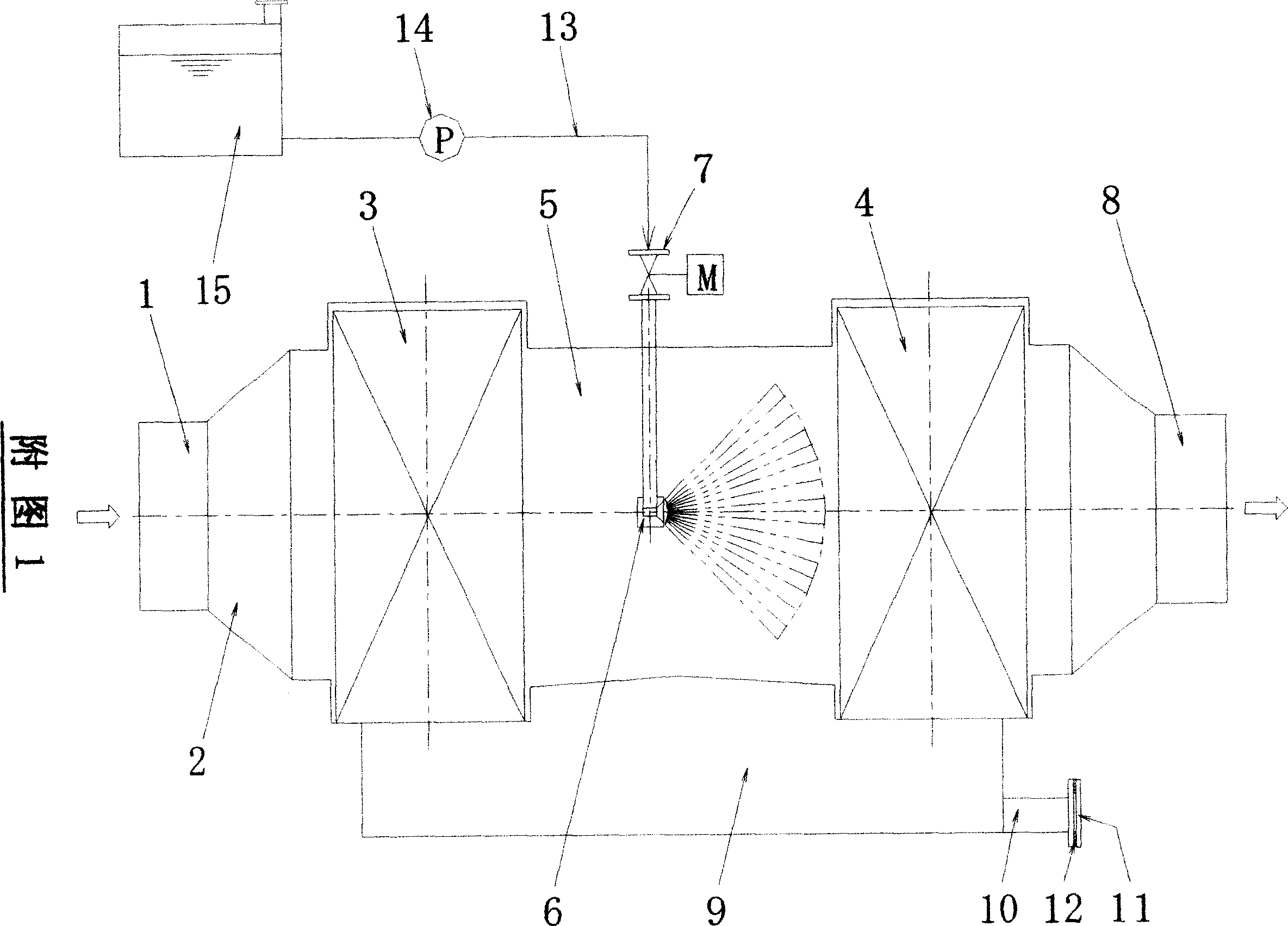

[0015] The device of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0016] As shown in Figure 1, when the exhaust gas produced by the incomplete combustion of the fuel internal combustion engine enters the exhaust gas inlet pipe 2 in the exhaust gas purifier housing 1, the exhaust gas after the separation and purification treatment by the first-stage exhaust gas purification device 3 There will be some turbulent flow, and the exhaust gas will flow into the second-stage exhaust gas purification device 6 after being rectified by the exhaust gas rectification channel 4 arranged at a distance between the first-stage exhaust gas purification device 3 and the second-stage exhaust gas purification device 6 at a distance of 800 mm to 1000 mm. Re-separation and purification are carried out. The spray sprinkler 5 in the exhaust gas rectification channel 4 is arranged in front of the second-stage exhaust gas purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com