Steel product excellent in corrosion resistance and corrosion fatigue resistance, and surface treatment method therefor

A corrosion resistance and surface treatment technology, applied in the direction of metal material coating process, can solve the problems of complex process, high production cost, hydrogen embrittlement and reduced material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0016] 1. According to the first embodiment of the present invention, a steel material excellent in corrosion resistance and corrosion fatigue resistance has a coating film on its surface, and in the average composition of the coating film, the number of Al atoms has a significant effect on Fe, The ratio of the total number of C, Al, P, O atoms and optionally added Si, Mn, Cr atoms is 0.5% or greater, and the number of Al atoms in the average composition of the coating film is greater than that in the average composition of the steel before surface treatment. number of atoms.

no. 2 approach

[0017] 2. According to the second embodiment of the present invention, a steel material excellent in corrosion resistance and corrosion fatigue resistance has a coating film on its surface, and in the average composition of the steel material surface to a region up to a depth of 5 μm, Al atoms The ratio of the number to the total number of Fe, C, Al, P, O atoms and optionally added Si, Mn, Cr atoms is 0.5% or more.

[0018] In the above two items of 1 and 2 of the present invention, "the ratio of the number of Al atoms to the total number of Fe, C, Al, P, O atoms and optionally added Si, Mn, Cr atoms" is based on elemental analysis , it is sufficient to measure the area from the steel surface to a depth of 5 μm for analysis. This area may be the cover film alone, or a combination of cover film and base material. "Si, Mn, Cr optionally added" means that none of these elements is added or at least one of these elements is added.

[0019] In item 2 of the present invention, the...

Embodiment

[0043] Some examples will be described below, but the present invention is not limited to these examples.

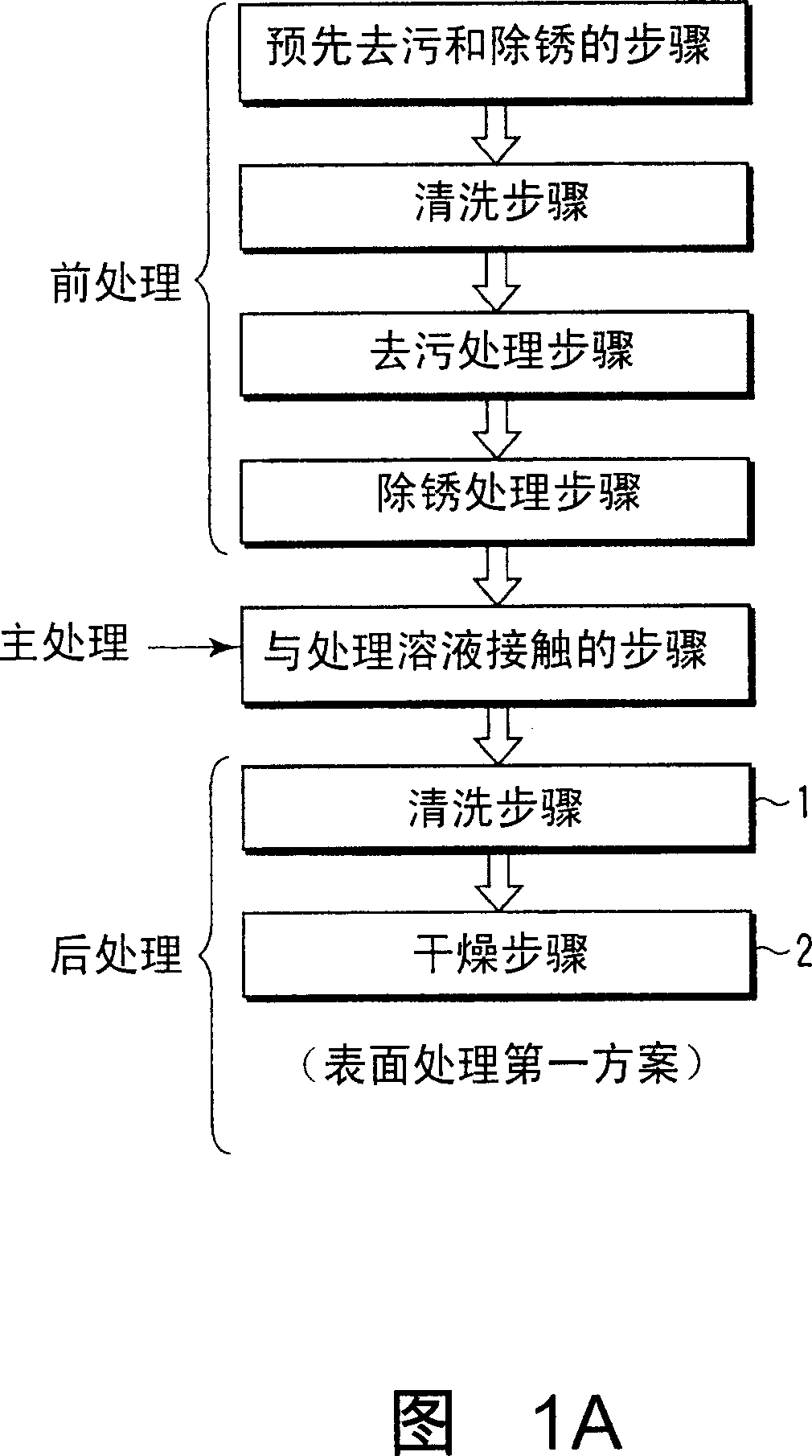

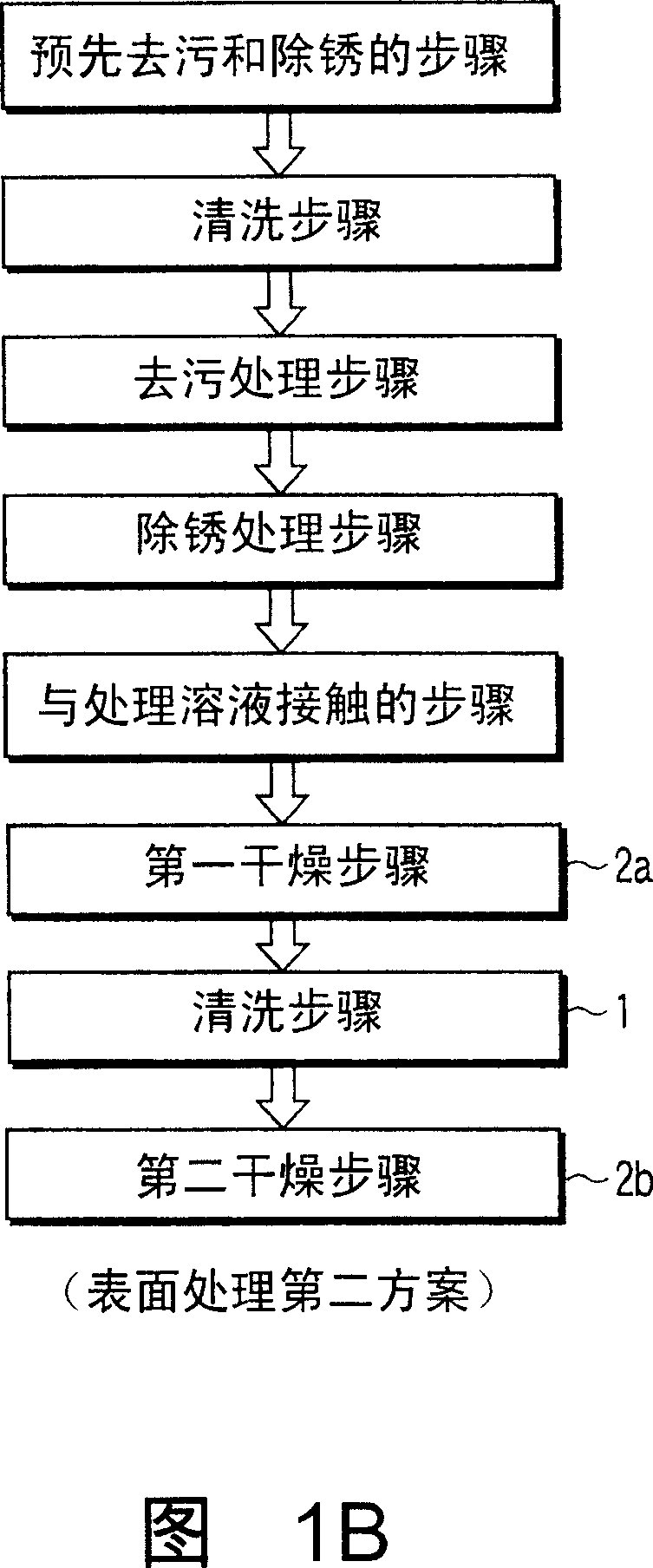

[0044] Take steel SAE 9254 (Fe-0.56%C-1.42%Si-0.75%Mn-0.68Cr) with a diameter of 4mm and a length of 20-80mm, and its surface is treated under various conditions in Table 1. The thick and dense oxidized rust is removed by spraying in advance to obtain the steel material used. The pretreatment step involves rinsing the steel with distilled water, desmutting it with acetone, and then immersing it in dilute aqueous hydrochloric acid to remove rust again. Then immerse the steel material to be surface treated in the treatment solution according to various conditions in Table 1, wash it with distilled water, and allow it to dry by itself (indicated by "-" in the row of 50°C drying in Table 1). The acidity ratio is controlled by adding an aqueous sodium hydroxide solution to the treatment solution. If necessary, after immersion in the treatment solution, the steel was dried i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com