Glutinous rice cake and its making process

A technology of glutinous rice and glutinous rice, which is applied in food preparation, confectionery, confectionery industry, etc., and can solve the problems of easy aging of the cortex, short shelf life, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

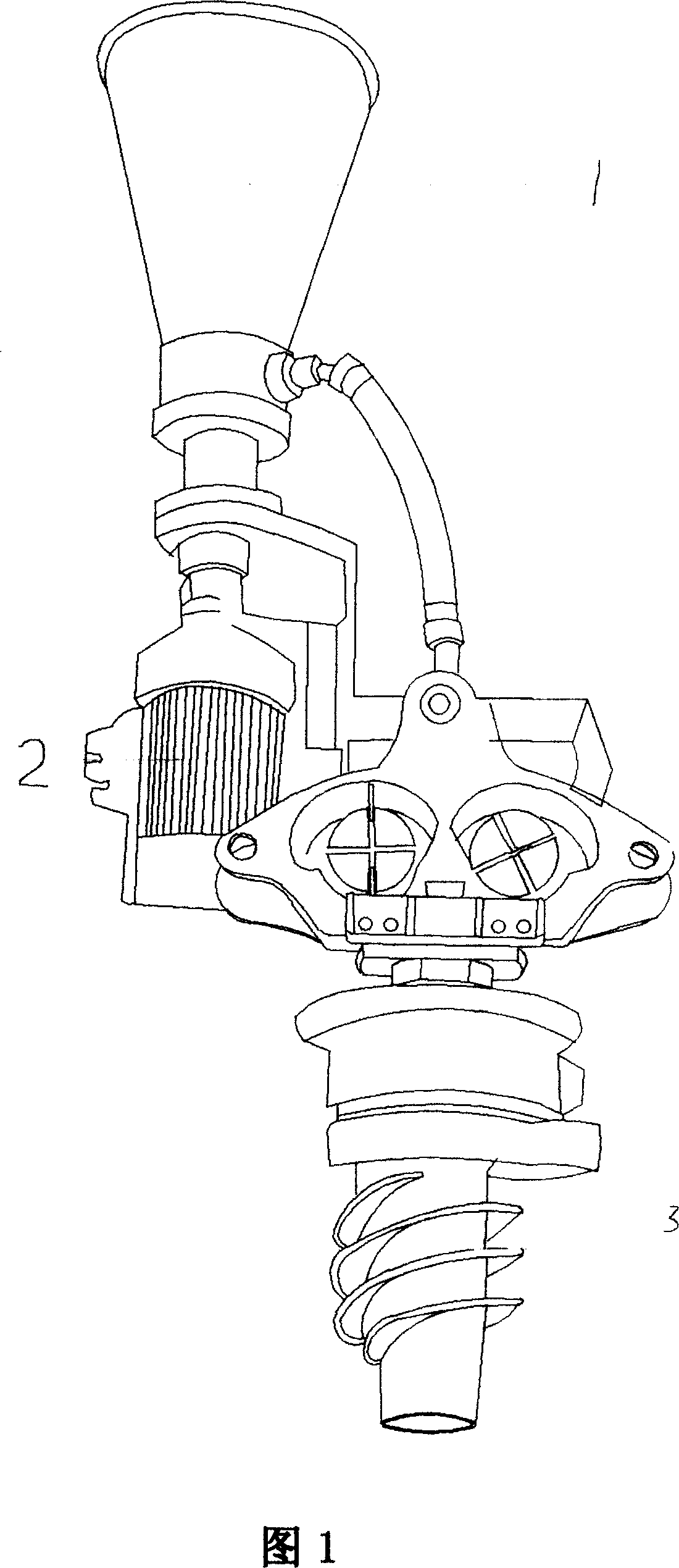

Image

Examples

Embodiment 1

[0064] Weigh each raw material: glutinous rice glutinous rice cake layer: 65kg, marshmallow layer: 15kg, inner filling: 20kg, described inner filling is made of the raw material of following weight kg: boiled soybean powder 23kg, white granulated sugar 30kg, high maltose syrup 30kg , vegetable oil 12.5kg, water 4.5kg, sodium dehydroacetate 0.05kg, BHA0.02kg (in oil basis); Described marshmallow layer is made of the raw material of following weight kg: white granulated sugar: 30kg, high maltose (concentration 84 ): 38.5kg, modified starch: 5kg, gelatin: 5.5kg, glucose: 10kg, water: 11kg; Described glutinous rice cake layer is made by the raw material of following weight kg: the maltooligosaccharide 65kg of concentration 75%, H78 powder ( Modified starch) 10kg, glutinous rice flour 5kg, sorbitol solution 5kg, sodium metaphosphate 0.1-2kg, sodium dehydroacetate 0.05kg, vanillin 0.03kg, water: 15kg.

[0065] Filling preparation method:

[0066] Pour the vegetable oil into the ste...

Embodiment 2

[0080] According to the method described in Example 1, glutinous rice cakes are prepared, and the required raw material formula is as follows:

[0081] Filling formula: 1. Cooked mung bean powder (red bean): 20kg 2. White sugar: 25kg3. Maltose syrup: 35kg 4. Vegetable oil: 10kg 5. Water: 9.93kg 6. Sodium dehydroacetate: 0.05kg 7. BHA: 0.02 kg (based on oil).

[0082] Marshmallow coating formula: 1. White granulated sugar: 25kg 2. High maltose (concentration 84): 31kg 3. Modified starch: 8kg 5. Gelatin: 7kg 6. Glucose: 14kg7, Water: 15kg.

[0083] The outer layer formula of glutinous rice bran: 1. Maltooligosaccharide (75% concentration): 60kg 2. H78 powder (modified starch) 15kg 3. Glutinous rice flour: 3kg 4. Sorbitol liquid: 3kg5. Sodium metaphosphate: 0.1~2kg 6 . Sodium dehydroacetate: 0.05kg 7. Vanillin: 0.03kg 8. Water: 19kg.

Embodiment 3

[0085] According to the method described in Example 1, glutinous rice cakes are prepared, and the required raw material formula is as follows:

[0086] Filling formula: 1. Cooked mung bean powder (red bean) 25kg 2. White sugar: 34kg 3. Maltose syrup: 23kg 4. Vegetable oil: 13kg 5. Water: 5kg 6. Sodium dehydroacetate: 0.05kg 7. BHA: 0.02kg( in oil).

[0087] Marshmallow coating formula: 1. White granulated sugar: 34kg 2. High maltose (concentration 84): 38kg 3. Modified starch: 8kg 5. Gelatin: 4kg 6. Glucose: 8kg7, Water: 8kg.

[0088] The outer layer formula of glutinous rice cake: 1. Maltooligosaccharide (75% concentration): 68kg 2. H78 powder (modified starch) 5kg 3. Glutinous rice flour: 8kg 4. Sorbitol liquid: 5kg5. Sodium metaphosphate: 0.1~2kg 6 . Sodium dehydroacetate: 0.05kg 7. Vanillin: 0.03kg 8. Water: 14kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com