Cement base material anticracking testing device and testing method thereof

A technology for cement-based materials and crack resistance, which can be used in measurement devices, analytical materials, material inspection products, etc., and can solve the problems of long test time, complex concrete force, and not a fast test method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

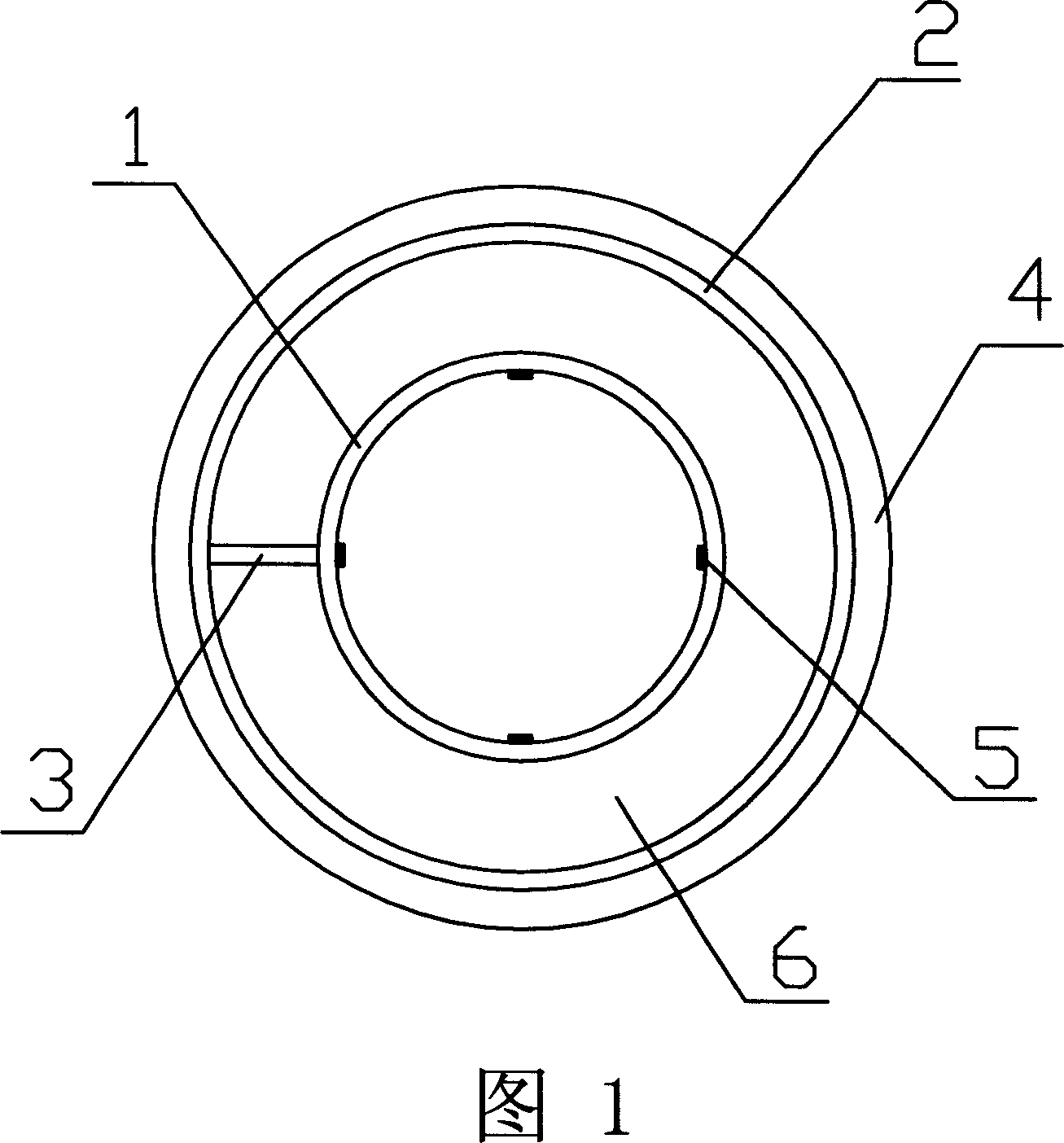

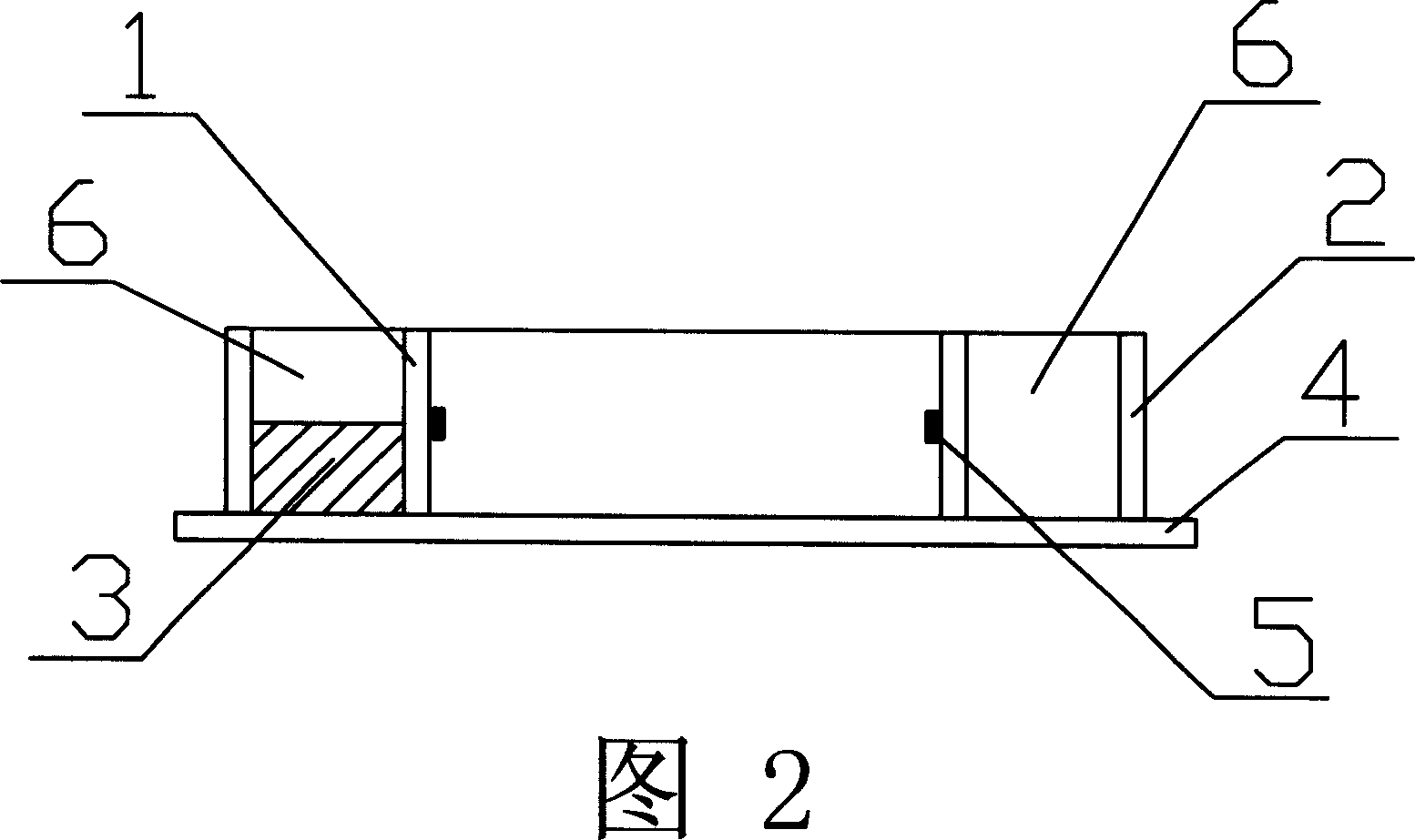

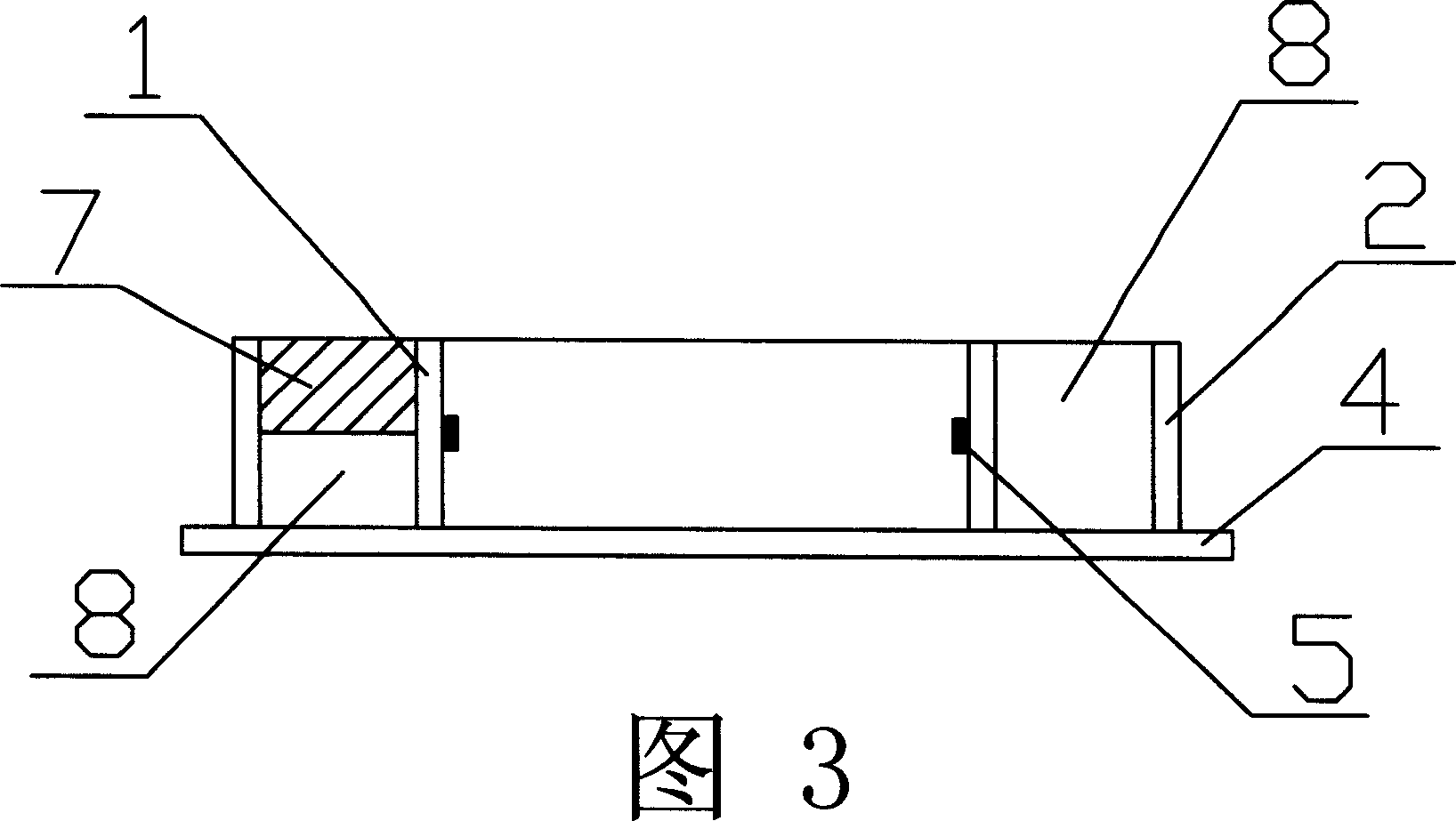

[0023] The difference between embodiment 1, embodiment 2 and embodiment 3 is that the positions and numbers of the connecting partitions are different, so as to change the size and position of the cracked interface of the tested cement-based material ring.

Embodiment 4

[0024] The difference between embodiment 4 and embodiment 1 is that the bottom plate 4 of embodiment 4 is elliptical, and the inner ring 1 and outer ring 2 are elliptical rings with the same focus. There are also three kinds of positions and quantities of connecting partitions provided in embodiment 4, which are the same as in embodiment 1, embodiment 2 and embodiment 3 respectively.

[0025] 3. Test method for crack resistance of cement-based materials

[0026] Pour cement-based materials between the inner ring 1, outer ring 2 and bottom plate 4, put them in a standard curing room or curing box for 8 to 24 hours, remove the outer ring 2, and seal them with waterproof materials such as asphalt wax or epoxy resin The upper surface of the cement-based material ring 6 is placed in an environment with a temperature of 20±2°C and a humidity of 20% to 70%, and the connection between the inner ring 1 and the bottom plate 4 is disengaged, so that the deformation of the inner ring 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com