Potassium hypermanganate and chloride united controlled milipore filter algae pollution pretreating method

A potassium permanganate, combined control technology, used in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of high ozone infrastructure costs and equipment investment, affecting drinking water safety, and inappropriate Emergency treatment and other problems to achieve the effect of improving algae removal rate, reducing self-use water consumption, and reducing infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add potassium permanganate and chlorine to the algae-containing water in the reservoir, the dosage of potassium permanganate is 0.3-2 mg / l, and the dosage of chlorine is 0.2-3 mg / l. The combination of the two can achieve a better treatment effect. Under different dosage ratios, they all have better algae removal effects. Compared with pre-chlorination alone, the removal rate of organic matter can be increased by more than 20%. Iron and The removal rate of manganese is increased by more than 30%, and the removal rate of algae is increased by more than 40%.

Embodiment 2

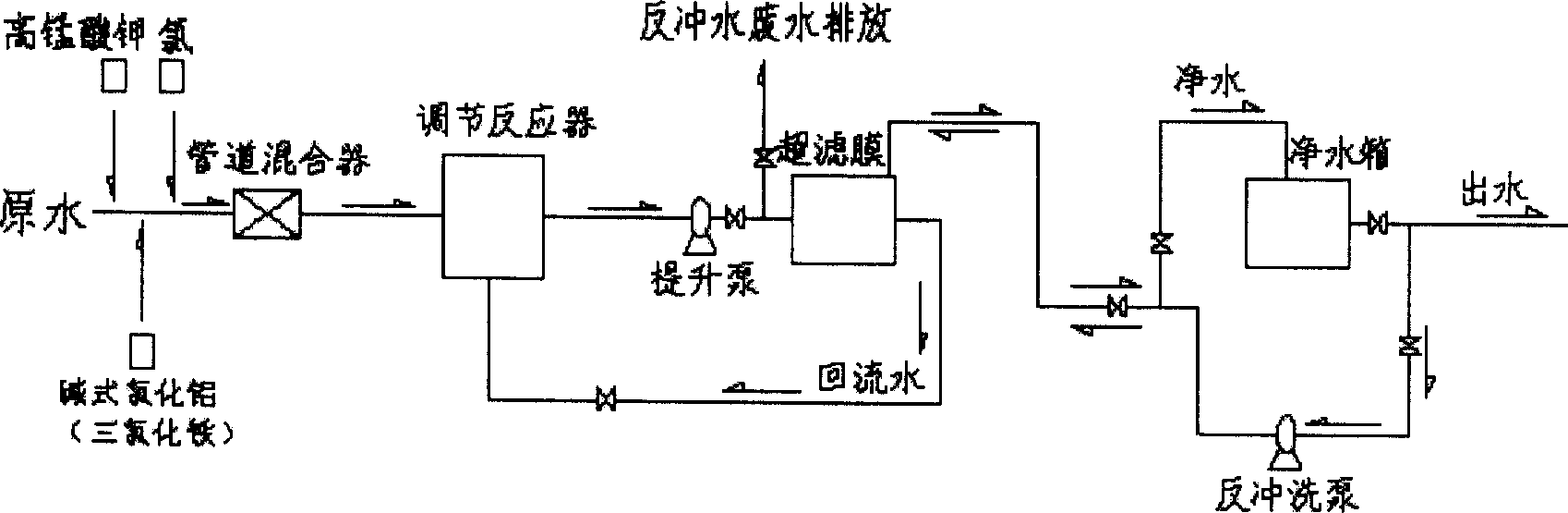

[0018] Add potassium permanganate and chlorine to the algae-containing water. The dosage of potassium permanganate is 0.3-2mg / l, and the dosage of chlorine is 0.2-3mg / l. The two oxidants are added at the same time, and then Add the coagulant basic aluminum chloride 1-10mg / l, after the pipeline is quickly mixed, after 5-10 minutes of flocculation reaction, the supernatant is pumped into the ultrafiltration membrane by the lifting pump, and passes through the cross-flow filtration of the ultrafiltration membrane module , The reflux ratio is controlled at 80-90%. The ultrafiltration membrane used is a hollow fiber structure made of organic synthetic material. During operation, the operating pressure of the ultrafiltration membrane is 0.05-0.2MPa, the backwash cycle is 45-120 minutes, and the backwash intensity is 200-300L / m 2 h, the backwashing time is 30-90 seconds. Compared with pre-chlorination alone, the ultrafiltration membrane backwash cycle can be extended by 15 to 45 mi...

Embodiment 3

[0020] The difference between this example and Example 2 is that the coagulant used is ferric chloride, the dosage is 3-15 mg / l, the flocculation reaction time is 10-20 minutes, and the reflux ratio is controlled at 80-95 %. The backwashing time is 30 to 120 seconds. Compared with pre-chlorination alone, the ultrafiltration membrane backwash cycle can be extended by 20 to 45 minutes, the removal rate of organic matter, iron, and manganese can be increased by more than 20%, and the removal rate of ultrafiltration membrane influent algae can be increased by more than 45%. Others are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com