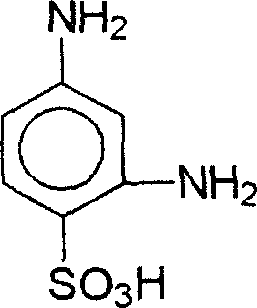

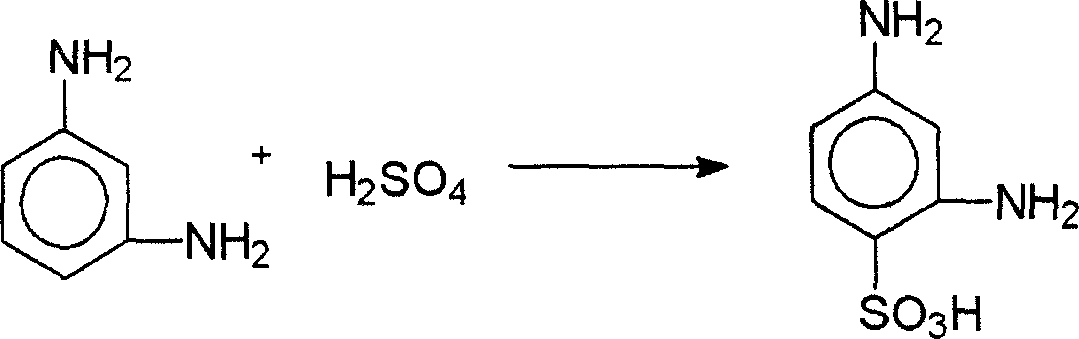

2,4-diamino benzenesulfonic acid and its salt synthesizing method

A technology of diaminobenzene sulfonate and diaminobenzene sulfonic acid, applied in 2 fields, can solve problems such as environmental pollution and rising production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the preparation method of the present invention, the sulfonation reaction is carried out in the temperature range of 160-250°C, preferably in the temperature range of 165-220°C, more preferably in the temperature range of 170-220°C, especially preferably at 175 It is carried out in the temperature range of ~220°C.

[0032] Amount of reactant

[0033] "Sulfuric acid" used in the present invention refers to sulfuric acid of any concentration or oleum of any concentration diluted to sulfuric acid of any concentration through water. For example, the sulfuric acid used in the present invention can be sulfuric acid with a concentration of 0.1-100% or any concentration of oleum diluted with water to 0.1-100% sulfuric acid. Sulfuric acid is more preferably sulfuric acid with a content of 60-100%, more preferably sulfuric acid with a content of 85-100%, particularly preferably sulfuric acid with a content of 90-100%.

[0034] The fuming sulfuric acid used in the preparation...

Embodiment 1

[0045] In reactor, add 100 milliliters of 98% sulfuric acid (184 grams) (corresponding to 100 percent sulfuric acid of 180 grams or 1.84 moles of 100 percent sulfuric acid) and 100 grams of 100% m-phenylenediamine (corresponding to 0.926 moles), after mixing, Raise the temperature to 181°C, react at 181-185°C for 4 hours, cool, add 400 ml of water, and purify by decolorization to obtain 168.8 g of 2,4-diaminobenzenesulfonic acid. The appearance of the obtained product is white crystal, the chromatographic content is 99% (as determined by HPLC), the chemical content is 98% (as determined by diazo titration), and the product yield is 95% (calculated as m-phenylenediamine).

Embodiment 2

[0047] Add 260 grams of 100% sulfuric acid and 100 grams of 100% m-phenylenediamine into the reactor, mix evenly, heat up to 210 ° C, react at 210-215 ° C for 4 hours, cool, add 400 ml of water, and purify through decolorization to obtain 159.9 grams of 2,4-diaminobenzenesulfonic acid. The appearance of the obtained product is white crystal, the chromatographic content is 99% (as determined by HPLC), the chemical content is 98% (as determined by diazo titration), and the product yield is 90% (calculated as m-phenylenediamine).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com